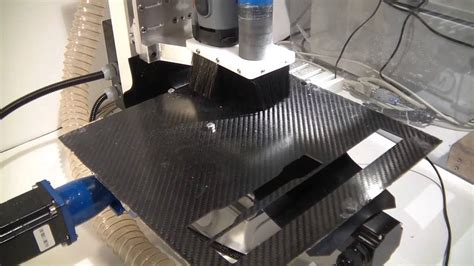

billet of carbon fiber for cnc machine Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes. What does a "1 Gang" mean when talking about electrical boxes? Example: CARLON 1-Gang Metal Adjustable Electrical Box (Lowes.com) It refers to the width of the box. A 1-gang box is wide enough for a switch or duplex receptacle. The idea is that you can "gang" up electrical components in the box.

0 · carbon fiber sheets prices

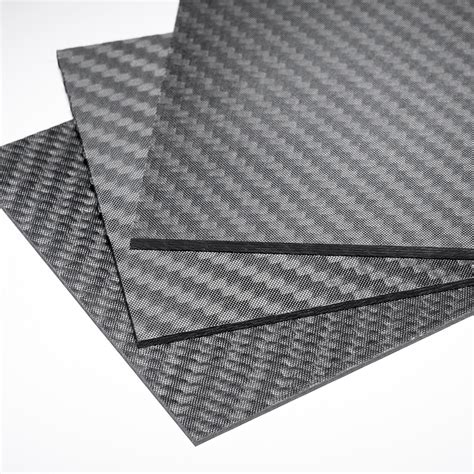

1 · carbon fiber sheets

2 · carbon fiber sheet milling

3 · carbon fiber sheet machining

4 · carbon fiber milling parts

5 · carbon fiber milling machine

6 · carbon fiber cutting parts

7 · carbon fiber cutting machine

What is a CNC Wood Router and How Does a CNC Router Work? A CNC wood router is a high-tech tool that has transformed how makers and craftsmen create and carry out difficult cuts on different materials, such as wood, plastic, or even soft metals.

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably.

Carbon Fiber Blocks and Billets. Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent . Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably.

Carbon Fiber Blocks and Billets. Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent wear-and-tear or where weight is at a premium.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes. That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with an 8" diameter 1" thick disc on top.

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. During machining, you are less likely to experience heating, which can damage your workpiece and degrade your machining tool. We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the.

CNC machining carbon fiber is a process that applies computer-controlled digital technology to remove the extra material and complete any necessary cutting, turning or milling. This can be done with machine tools depending on what's needed for your specific programmings before getting an end product from carbon fiber in their final form.We stock a wide range of billet carbon fiber composites for machining in thicknesses up to 6". Karman Innovations' custom additive manufacturing solutions help our customers produce low volume field ready components with properties that meet or exceed their current metal or composite components.DragonPlate is a leading innovator in high-performance carbon fiber-reinforced composites. From custom carbon fiber shapes, to products including tubes, sheets, plates and more, DragonPlate has a solution to fit you. The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably.

Carbon Fiber Blocks and Billets. Our carbon fiber blocks and billets boast a lower density and a higher strength-to-weight ratio than traditional materials, making them the superior choice for products that face frequent wear-and-tear or where weight is at a premium.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

carbon fiber sheets prices

That's right, you heard right, "billet" carbon fibre. Actually not a billet of solid material, but 250 layers of carbon/resin cloth autoclaved into a 20" square about 2" thick with an 8" diameter 1" thick disc on top. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. During machining, you are less likely to experience heating, which can damage your workpiece and degrade your machining tool. We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the.

injection moulding cnc machines

CNC machining carbon fiber is a process that applies computer-controlled digital technology to remove the extra material and complete any necessary cutting, turning or milling. This can be done with machine tools depending on what's needed for your specific programmings before getting an end product from carbon fiber in their final form.We stock a wide range of billet carbon fiber composites for machining in thicknesses up to 6". Karman Innovations' custom additive manufacturing solutions help our customers produce low volume field ready components with properties that meet or exceed their current metal or composite components.

industrial metalmecanica

carbon fiber sheets

carbon fiber sheet milling

Metallic fiber is manufactured fiber composed of metal, plastic-coated metal, metal-coated plastic, or a core completely covered by metal. These are light weight and relatively inexpensive yarns.

billet of carbon fiber for cnc machine|carbon fiber sheets prices