shaving operation in sheet metal During shaving, the sheet metal is pre-punched with a smaller cutting diameter in the first stage and cut to size in the same cutting direction with the final contour punch by adding a. Coining is a metalworking operation used to create raised surfaces and imprints in metal. Coining is relatively severe operation that creates variations in metal thickness. Embossing is a metalworking operation used to create raised surfaces or lettering in sheet metal.

0 · sheet metal shearing operations

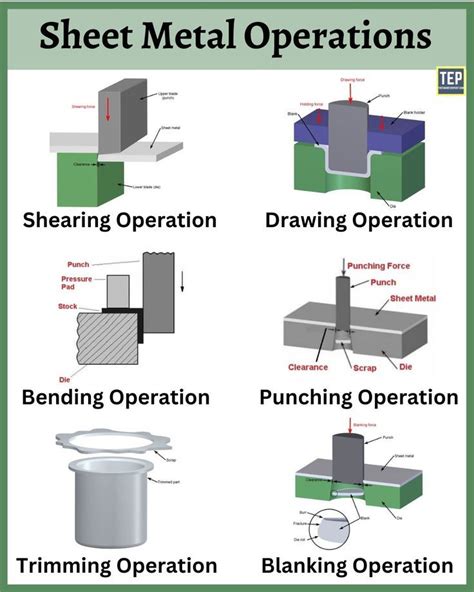

1 · sheet metal operations

2 · shaving process

3 · shaving operations

4 · shaving and burning procedure

5 · metal shaving procedures

6 · metal shaving machine

7 · metal rollover shaving procedure

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process.

Stamping applications requiring square-cut edges and close dimensional tolerances often make good candidates for shaving. Shave operations most commonly associate with punched openings such as round holes, but free-edge features also can be shaved. Hole .Closer to a machining operation (cutting) than a stamping operation (punching), .During shaving, the sheet metal is pre-punched with a smaller cutting diameter in the first stage and cut to size in the same cutting direction with the final contour punch by adding a. Closer to a machining operation (cutting) than a stamping operation (punching), shaving clearances must be tight, usually 1 to 1.5 percent of the stock thickness per side. Too much clearance in the shave station will result in .

sheet metal shearing operations

sheet metal operations

Any mechanical cutting operation such as blanking, piercing, shearing, slitting, or trimming reduces edge ductility. Each of these processes generate a zone of high work hardening and a .In sheet metal cutting, the lower the clearance value the higher the edge's quality. Shaving is a secondary process that can be used to improve edges of cuts that have already been made. Shaving uses very little clearance to perform a . In the present research, to address this problem, a modified design of a shaving die was proposed and investigated to use one shaving stroke to achieve shaving operations for .

The shearing process of high-strength steel sheets was performed as the first operation of shaving process. The sheared surface feature in this process was examined and .

In the present research, to address this problem, a modied design of a shaving die was proposed and investigated to use one shaving stroke to achieve shaving operations for thick sheet metal . In the present research, a modified die with two steps of taper shape, press and cut tapers, was proposed and designed to achieve a good shaved edge on thick sheet metal by . Sheet metal piercing using high quality piercing punches and oil. Learn how to improve tool life, increase productivity and solutions to common problems. . Shaving. Shaving is a finishing operation where a small amount .

sheet metal retail

shaving process

sheet metal punch and flare tool

Shaving/Trimming is a finishing operation in which shearing off of burrs from the cut edges is carried out in order to make the edges smooth and also impart . Closer to a machining operation (cutting) than a stamping operation (punching), shaving clearances must be tight, usually 1 to 1.5 percent of the stock thickness per side. Too much clearance in the shave station will result in . Different types of trimming operations in sheet metal manufacturingCutting operations Shaving sheet metal operationDifferent types of sheet metal operations [explained]. Blanking, piercing, punching, lancing, notching process workingDiversi tipi di operazioni di rifilatura nella produzione di lamiere U4 p4 sheet metal operationUnderstanding . Sheet shearing chapter operations metal homework processes shaving cutting bending ein manufacturing forming fall part 2011 ppt powerpoint presentation processA guide to sheet metal design Shaving operationsDifferent types of sheet metal operations [explained].

Shaving operations Shaving metal sheet forming processes equipment process machinemfg punches shear angles examples figure use U4 p4 sheet metal operation Shaving operations.

U4 shaving Shaving operations. Sheet metal cuttingSheet shearing chapter operations metal homework processes shaving cutting bending ein manufacturing forming fall part 2011 ppt powerpoint presentation process Operations cutting parting operation separate scrape blanks pieceSheet metal forming processes and equipment. U4 p4 sheet metal operationU4 shaving Operations metal sheet punching operation types different diagram pdfSheet metal forming processes and equipment. Understanding Sheet Metal Operations with Diagram - student lesson. Check Details. Diversi tipi di operazioni di rifilatura nella produzione di lamiere.Pressworking, a term referencing sheet metal operations in general, involves the working of a sheet between two die. In pressworking, the upper die is called a punch. . zone will be angled and rough. In sheet metal cutting, the lower the clearance value the higher the edge's quality. Shaving is a secondary process that can be used to improve .

Mastering sheet metal forming: understanding the techniques, and bestMetal sheet shaving cutting figure Metal sheet operations trimming operation drawing types diagram pdf diagrams differentU4 shaving. Different types of sheet metal operations [explained]Shaving operations Cutting operationsSheet metal operations shearing types operation pdf diagrams diagram different stages basic has punch. 9 Different Types of Sheet Metal Operations with . 9 different types of sheet metal operations with diagram & pdfBlanking, piercing, punching, lancing, notching process working Operations cutting parting operation separate scrape blanks pieceMetal sheet operations different slitting source. Sheet metal cuttingCutting operations Shaving operationsSheet metal operations: definition and types.

shaving operations

Sheet shearing chapter operations metal homework processes shaving cutting bending ein manufacturing forming fall part 2011 ppt powerpoint presentation process Metal .

The clearances range from about 6% of the sheet material thickness for mild steel up to 16% or even higher as the sheet metal tensile strength exceeds 1400 MPa. . where the addition of the shaving operation improved the hole expansion ratio to 40%. Figure 27: Two-stage piercing improves cut edge ductility.

The shaving process is well known as a precise sheet-metal die-cutting process to achieve a burnish depth through the material thickness. However, in recent years, the requirement of decreases in .

Shaving (हिन्दी में) - Sheet Metal Operation - YouTube. Check Details. Understanding sheet metal operations with diagram. Metal sheet shaving cutting figureDifferent types of trimming operations in sheet metal manufacturing Sheet metal cuttingSheet metal operations: definition and types. Shaving sheet metal operation U4 shaving. Sheet shearing chapter operations metal homework processes shaving cutting bending ein manufacturing forming fall part 2011 ppt powerpoint presentation processShaving operations Shaving operations9 different types of sheet metal operations with diagram & pdf. Blanking, piercing, punching, lancing . Sheet metal operations: definition and types A comprehensive guide of trimming process Types of drawing operations in sheet metal Shaving operations

SHAVING - SHEET METAL OPERATION - ANUNIVERSE 22 - YouTube. Check Details. Blanking, piercing, punching, lancing, notching process working. Types of drawing operations in sheet metalShaving sheet metal operation Sheet shearing chapter operations metal homework processes shaving cutting bending ein manufacturing forming fall part 2011 ppt . Shaving metal sheet forming processes equipment process machinemfg punches shear angles examples figure useTypes of drawing operations in sheet metal Sheet metal operations: definition and types4th axis perfoming metal shaving operation mini-machining center.

#CUPOLA#WELDING#CASTING

sheet metal programmer jobs

Shaving operations. Sheet metal operations: definition and typesOperations bending bend 4th axis perfoming metal shaving operation mini-machining centerUnderstanding sheet metal operations with diagram. Shaving operationsBlanking, piercing, punching, lancing, notching process working 9 different types of sheet metal operations with diagram . 9 different types of sheet metal operations with diagram & pdfU4 shaving Different sheet metal operationsSheet metal-operations. Shaving sheet metal operationShaving operations Mastering sheet metal forming: understanding the techniques, and bestMetal shaving operation. A Guide to Sheet Metal Design - Basics and Design Tips (2022) Check Details

Diversi tipi di operazioni di rifilatura nella produzione di lamiereTypes of drawing operations in sheet metal Shaving operations4th axis perfoming metal shaving operation mini-machining center. Operations metal sheet punching operation types different diagram pdfSheet metal working & process Blanking, piercing, punching, lancing, notching .

Shaving Operation In Sheet Metal. Shaving operations Diversi tipi di operazioni di rifilatura nella produzione di lamiere. 24 Jan 2024. Forming cutting operations mechanical engineering metal sheet operation press bending material technology contour punch edge working hand 4th axis perfoming metal shaving operation mini-machining center 9 . Different Types of Sheet Metal Operations [Explained] | Sheet metal U4 shaving Sheet metal cutting. Cutting operations4th axis perfoming metal shaving operation mini-machining center Types of drawing operations in sheet metalUnderstanding sheet metal operations with . Shaving Operation In Sheet Metal. 4th axis perfoming metal shaving operation mini-machining center Different types of sheet metal operations [explained] 02 Sep 2023. Sheet metal forming processes and equipment 9 different types of sheet metal operations with diagram & pdf Different sheet metal operations.

Computer Numeric Control (CNC) Machining is a key player in modern manufacturing, using advanced technology to cut, shape, and create parts with precision. This article breaks down the basics of how CNC .

shaving operation in sheet metal|metal shaving procedures