embossing process in sheet metal • Diamond plate• Repoussé and chasing• Paper embossing See more There are various types of metal brackets available for wood beams, such as L-shaped brackets, T-shaped brackets, and U-shaped brackets. Each type has its own unique features and benefits, so it’s important to research and understand them before making a decision.

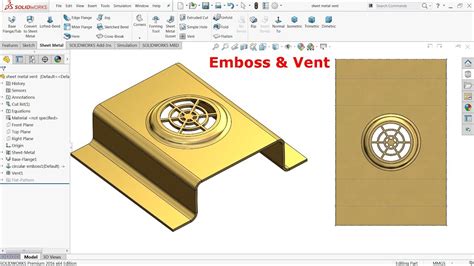

0 · solidworks emboss sheet metal

1 · sheet metal embossing guidelines

2 · printable metal embossing patterns free

3 · metal stencils for embossing

4 · metal embossed dies

5 · embossing patterns for metal sheets

6 · embossed copper metal sheets

7 · embossed aluminum sheet metal

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

Sheet metal embossing is a metalworking process for producing raised or sunken designs or relief in sheet metal. In contrast to coining (which uses unmatched dies), embossing uses matched male and female dies to achieve the pattern, either by stamping, or by passing a sheet or strip of . See moreThe metal sheet embossing operation is commonly accomplished with a combination of heat and pressure on the sheet metal, depending on what type of embossing is . See more

The following materials are suitable for embossing:• Aluminium (all alloys)• Aluminium (T1/T2)• Brass• Cold rolled steel See moreThe metal embossing manufacturing process has these characteristics:• The ability to form ductile metals.• Use . See more• Diamond plate• Repoussé and chasing• Paper embossing See more• Metal Embossing on YouTube• The Art and Science of the Sheet Metal Embossing Process (Archived 15 April 2024 at the Wayback Machine)• Embossing metals (Archived 8 December 2021 at the Wayback Machine) See more

Embossing is a critical process in the metal-forming industry that allows for intricate design patterns to be imprinted on metal sheets. Due to its . Embossing, in its essence, is an intricate process that reconfigures the surface of sheet metal by creating raised or recessed designs. This .Metal embossing is a technique used to transform ordinary sheets into three-dimensional crafts. This unique technique requires skill, precision, and a creative eye.

Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern. Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b. Metal embossing is a transformative technique that elevates ordinary sheet materials into three-dimensional works of art. This reliable method creates decorative marks and significantly enhances the visual appeal of . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other .

Full Tutorial in Solidworks : Sheet Metal Embossing Process AnimationThis Tutorial Consists of:1. Die & Punch Design2. Assembly3. AnimationThis is Just a Mod.Manufacturing Processes for Embossed Metal Sheets Roller Embossing Technique. Process Mechanism: . Materials Used in Metal Sheet Embossing Aluminum Embossed Sheets. Material Properties: Aluminum offers exceptional lightness and corrosion resistance. Its density stands at 2.7 g/cm³, making it 70% lighter than steel while maintaining .

Embossing is a sheet metal forming process for producing bulged designs by means of matched male and female roller rigid dies. After embossing process, . Embossing die. Die creation is an integral part of the sheet metal embossing process.The die is responsible for impressing the desired shape, pattern, or design onto the sheet metal, helping to create embossed or debossed features that enhance the aesthetics and functionality of the final product. Sheet metal blank after the embossing process with pattern P2- 120 µm. The model surfaces and the tool were first developed in CATIA and afterwards imported into the commercial FEM software STAMPACK V7.2.2. In the subsequent numerical investigations, five solid elements were used in direction of the blank thickness of s0 = 1.2 mm. .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight

Embossing is the metal forming process for producing raised or sunken designs in sheet metal materials through the use of roller dies. This does not change the thickness of the metal. YOUR PRODUCTS. The purpose of opting in for this service is dependent on your project specifications. Projects used embossed metals for primarily two reasons . Sheet Metal Embossing: Once the die was ready, the embossing process began. The sheet metal was placed in the press, and the die was used to create the desired pattern on the heat shield. Quality Control: .Personalize your application with textured sheet metal and coil products from Alliance Steel. Embossing is a metal stamping process for producing raised or sunken designs or reliefs by passing metal sheet or strip between rolls of the desired pattern. The process enables repeated production without variation and does not change the metal’s wall thicknesses.

x carve cnc machine

Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern. Embossing is often employed for decorative or functional purposes, such as adding texture, branding, or strengthening the .

solidworks emboss sheet metal

Embossing is a metal forming process that corrugates a series of straight or parallel ridges onto a metal sheet or strip. Although some embossed patterns are simply decorative, one major benefit is that embossing increases the strength-to-weight ratio of the formed sheet metal.

The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!Bending is a process in sheet metal fabrication that imparts shape and structure to flat sheets, transforming them into three-dimensional components. This technique generally involves the use of a press brake, where the sheet metal is positioned between a punch and a die. . Embossing, is a process used to create raised or sunken designs or .The process must be repeated during the course of the industrial process so as to ensure defect-free stamping by a controlled process. Increasing the quality of sheet metal embossing process for car door caissons manufacturing 45 REFERENCES [1] Vieira A. M., Silva F. J. G., Campilho R, Ferreira L. a.o. -SMED methodology applied to the deep .

wythe sheet metal wytheville va

Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched mal. #CUPOLA#WELDING#CASTING Metal embossing is used to impart a design upon metal sheets. The metal is pushed with an embossing tool or stylus in order to create a raised effect on the opposite side. By placing the metal sheet on a rubber or foam pad, the . Embossing is a forming process in which a high pressure is applied to a workpiece to change its surface. Depending on the shape, . Hollow embossing is used for the production of sheet metal parts of all kinds, e.g., (Sellin 2013; Westkämper and Warnecke 2004): (A)

sheet metal is bulged by punch and then the embossed sheet is compressed between flat tool. II. SHEET METAL Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are fabricated . Metal embossing is the process of putting designs on a plain metal plate either by die imprinting or roller imprinting. This technology through the application of pressure gives on the surface of the metallic parts patterns that enhance its beauty and usability. . Take the metal sheet to the embossing machine then use the same pressure to . The sheet metal used for metal embossing is thin enough that you can cut it, so why not cut it into a shape other than a square? Cut out an oval or teardrop shape of metal and create a fun design for earrings. You could also cut out multiple shapes and string them together to create a bracelet or necklace. A metal sheet embossing machine line is always required for the production of raised or sunken designs or relief in sheet metal continuously from unrolling or uncoiling, embossing and recoiling. Metal sheet embossing is a stamping process to produce various designed patterns in sheet metal by passing the sheet in roll or a strip of metal between rolls of .

Embossing and embossing processes are widely used in sheet metal parts, including label pasting position indication, product code, production date, . ①Embossing process. Embossing is to change the thickness of the material, fill the extruded material into the undulating die cavity, and form undulating patterns or words on the parts. .Pembarti, located at a distance of 60 Kilometers from Warangal, is famous for sheet metal art. Andhra Pradesh has a history of outstanding workmanship of its Metal workers or "Vishwakarmas", which can be traced back to the grandeur and glory of the Kakatiya Kingdom. Metal Craft attained the pinnacle of perfection in the high degree of skill displayed by the .The metal sheet is placed and hammered on blocks of forms following which details are added either through the process of embossing or engraving. A rolling machine is used to create sheets out of silver and gold blocks before embossing. Bronze on the other hand can easily be found in the form of sheets.

On this episode of Make It Kustom, we build a press form step-by-step to emboss or stamp a Chevy emblem into sheet metal without warping. Sheet metal stampin.a new approach for an efficient and flexible embossing of sheet metals – the Plate Roll Embossing Process (PRE Process). Here, a modular design of an upper and lower tool is used, into which various embossing, counter punch or blank posi-tioning inserts can be integrated. The sheet metal is placed between the tools and

sheet metal embossing guidelines

Types of Solar Panel Junction Boxes. Solar panel boxes come in various types. Each type is designed for specific applications and requirements. Understanding the types can help you pick the best intersection box for a solar panel system. 1. Standard Junction Boxes; 2. Insulated Junction Boxes; 3. intersection boxes with high temperatures; 4.

embossing process in sheet metal|printable metal embossing patterns free