hemming metal sheet A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a . See more $179.99

0 · types of sheet metal seams

1 · sheet metal hem design guide

2 · sheet metal hand hemming tool

3 · seaming process in sheet metal

4 · seam joint in sheet metal

5 · open hem sheet metal

6 · hemmed edge sheet metal

7 · hem300 vs hem305

$5.18

Hemming in sheet metal operations refers to the bending of a sheet metaledge onto itself. It is very similar to edge stitching in clothes. Similar to how an edge stitch strengthens the . See moreThe hemming process can be carried out in one of the following two ways: 1. Die hemming process 2. Roller hemming process See more

A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a . See more Hemming in sheet metal fabrication refers to the process of folding a piece of metal over onto itself to conceal an edge or burr, provide added strength, or achieve a smooth aesthetic appearance. What are the four most . Sheet metal hemming is a manufacturing process that folds metal edges to reinforce strength and safety. It reduces sharpness and enhances aesthetics, often used in . Sheet metal hemming is a standard method for improving the quality and appearance of your sheet metal products. This article discusses the principle behind sheet metal hemming, its purpose, and how you can get the .

Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in .

Sheet Metal Hemming Vs. Sheet Metal Seaming. The rolling over of a sheet metal edge onto itself is known as hemming in the metalworking industry. Hemming includes rolling the edge flush against itself instead of sewing, which joins the .

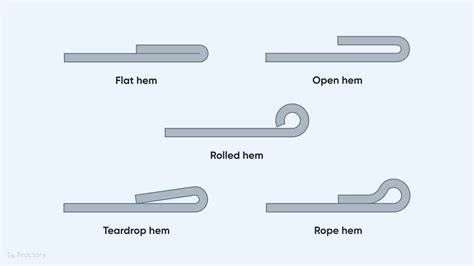

Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. This process adds durability and strength to the part but eliminates sharp edges. It ensures . In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet .What is Hemming in Sheet Metal? How to Hem Sheet Metal? Different Types of Sheet Metal Hems; Processes of Sheet Metal Hem; Pros and Cons of Hemming in Sheet Metal; Tips for .

Master sheet metal hemming with our comprehensive guide. Explore processes, applications, and best practices for professional-looking metal edges. Improve your fabrication skills today! What is the preferable length of a hem on sheet metal? For open hems, The preferred hem length should be between 0 and 2mm. 16 to 0. It ranges from 5 inches and may vary depending on the sheet metal thickness. Closed .

In car part production, hemming is used in assembly as a secondary operation after deep drawing, trimming and flanging operations to join two sheet metal parts (outer and inner) together. Typical parts for this type of assembly are hoods, doors, trunk lids and fenders.

Sheet Metal Hemming vs Seaming. As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded .hemming process A closed hem A seam. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. [1]Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance.

Hem Types in Sheet Metal Hemming Open. The open hem type allows you to fold the edge of the sheet metal to a 180-degree angle while leaving some space between the hem part and the primary sheet metal area. You can use the open hem space for various purposes, such as to ease the assembly process.Hemming is a forming and joining technique used in sheet-metal working. This technology can be used to join components of the same material or different materials – one reason why the process is frequently used in the automotive industry. . In hemming, the sheet-metal parts are bent in a forming process and then positively joined by welding .

Hemming (or flattening) is a great way to finish sharp edges and to strengthen parts after bending sheet metal. +31 573 289 850 Find your local dealerAJC Sheet Metal Folding & Hemming Tool (15.25 Inches) 4.3 out of 5 stars. 42. .00 $ 59. 00. FREE delivery Mon, Nov 25 . Only 20 left in stock - order soon. Add to cart-Remove. HURRICANE 18 Inch Folding Tool, Sheet Metal Bending Tool for HVAC, Bending and Forming Metal. 4.5 out of 5 stars. 718.

types of sheet metal seams

Sheet Metal Hemming vs Seaming. As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded . Answer: Let’s begin by looking at the hem. While those in the sheet metal trade form dozens of different kinds of hems and seams, most are simply outdated, and only three are in general use. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the Fabricators & Manufacturers Association International®. Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Common sheet metal design guidelines in Hem Feature Guidelines or Hem. Metal Hemming Machine. A metal hemming machine is a specialized piece of equipment used in sheet metal fabrication and manufacturing processes. It is designed to fold, bend, or curl the edges of metal sheets, creating secure, .

KDM sheet metal hemming machine is manufactured under the strict quality control. KDM can provide you sheet metal hemming machine with full certifications. KDM manufacturing company is really your one-stop-shop sheet metal hemming machine solutions. To get benefits with our 15 years of experience, please don’t hesitate to contact KDM team now! The process, called hole hemming, involves deforming the metal sheet to establish a mechanical interlock with the polymer sheet, requiring neither heating nor auxiliary elements. The applicability of this process is tested for joining aluminum and polycarbonate (PC) sheets. Initially, an analytical design method is presented to achieve a . Hemming suits only high-gauge sheet metal (thinner sheets <=0.125”). Low-gauge sheets (thicker sheets) are prone to fracturing on bending. How Sheet Metal Hemming Works. Sheet metal hemming is a multi-step . This video discusses the different commonly used connection joints found on Sheet Metal Duct work.

Hello all I would like to use the hem feature on a curved feature, as the one below. Inventor hem feature does not recognize the inner bottom edge as a valid edge for hemming. I understand that it can be seen as an impossible . Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. This paper present a systematic review of sheet metal hemming process based on materials used in hemming process .Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the world of sheet metal hems. I’ll show you the importance of these hems and the types of hems available, and .

stalwart 22.5 in. rolling stacking portable metal trolley tool box

A hemming tool is a device used in sheet metal fabrication to create a folded edge, also known as a hem, on a metal sheet. It is commonly used in industries such as automotive, aerospace, and construction. The tool consists of a clamping mechanism that holds the metal sheet in place and a folding blade that bends the edge of the sheet to create . Hemming is a crucial process in sheet metal fabrication that involves bending and folding the edge of a sheet metal onto itself to achieve several key. Products Product Category PRESS BRAKE TOOLINGS PANEL BENDING TOOLS SHEAR BLADES PUNCHING AND IRONWORKER TOOLS LASER ACCESSORIES . AJC Tools & Equipment AJC Tools AJC Sheet Metal Folding & Hemming Tool (11.25 Inches) Recommendations Midwest Snips MIDWEST Seamer - 15 Inch Offset Sheet Metal Bender with Aluminum Blades & KUSH'N-POWER Comfort Grip Handle - MWT-SO15

The gauge, of course, refers to the thickness of sheet metal. High-gauge sheet metal is thicker than low-gauge sheet metal, which can make it difficult to manipulate using processes like hemming. With the right tools, however, manufacturing companies can hem sheet metal by bending and rolling the edge over and onto itself. In order to join two ultra-high strength steel sheets with low ductility for automobile parts, a joining process by hemming with a pre-bent inner sheet was developed. In this joining, the pre-bent inner sheet instead of the conventional flat inner sheet was used to relax the deformation concentration of the outer sheet. Although 780 MPa steel sheets were joined without the pre . Sheet metal hemming process can be generally classified into two major categories such as Classical (conventional) hemming and roller hemming process. Fig. 1 depicts three different steps of conventional sheet hemming in which an inner sheet is placed over outer sheet and with help of punch outer sheet is bent to form hem with the help of rigid .Our 3/4″ QuickHem machine This machine is a real time-saver for your production requirements allowing you to hem and fabricate metal on your schedule and not someone else’s! . Ideal for roofing contractors, sheet metal fabricators, and HVAC shops. Form your hem/kick and finish it to the desired shape with your brake.

Here we demonstrated the hemming process in press brake machine.

stamped sheet metal parts suppliers

Design styles three-tier wall file holder – Durable black metal rack with spacious slots for easy organization, mounts on wall and door for office, home, and work. This metal file holder is the perfect solution for loose papers and a messy desktop.

hemming metal sheet|seam joint in sheet metal