at a fabrication plant a hot metal At a fabrication plant, a hot metal forging has a mass of 76 kg and a specific heat capacity of 430 J/(kg Request Service Online - White's Heating and Sheet Metal | Seaside, Oregon .

0 · Solved At a fabrication plant, a hot metal forging has a

1 · Solved 49. At a fabrication plant, a hot metal forging has a

2 · SOLVED:At a fabrication plant, a hot metal forging

3 · SOLVED: At a fabrication plant, a hot metal forging has a

4 · Problem 49 At a fabrication plant, a hot me [FREE SOLUTION]

5 · For the first question: Calculate Initial Temp of Forging (76kg,

6 · At a fabrication plant, a hot metal forging has a mass of 75 kg and

7 · At a fabrication plant, a hot metal forging has a mass of 72

8 · Answered: At a fabrication plant, a hot metal

$51.99

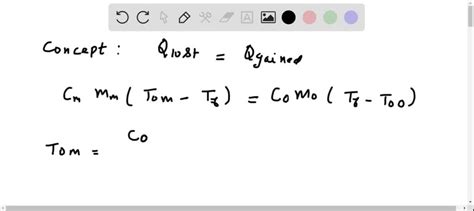

At a fabrication plant, a hot metal forging has a mass of 76 kg and a specific heat capacity of 430 J/(kg At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J/(kg • °C). To harden it, the forging is immersed in 710 kg of oil that has a temperature of . To find the initial temperature of the forging, we can use the principle of heat transfer. The heat gained by the oil is equal to the heat lost by the forging. The equation for .At a fabrication plant, a hot metal forging has a mass of 75kg and a specific heat capacity of 430 J/(kg.C°). Toharden it, the forging is immersed in 710 kg of oil that has atemperature of 32 °C .

Solved At a fabrication plant, a hot metal forging has a

Solved 49. At a fabrication plant, a hot metal forging has a

At a fabrication plant, a hot metal forging has a mass of 72 kg and a specific heat capacity of 500 J/(kg C). To harden it the forging is immerse in 840 kg of an oil that has a temperature of 32 C .At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J / (kg ⋅ C ∘). To harden it, the forging is immersed in 710 kg of oil that has a temperature of 32 .At a fabrication plant, a hot metal forging has a mass of 71.3 kg and a specific heat capacity of 427 J/(kg C°). To harden it, the forging is quenched by immersion in 717 kg of oil that has a .

At a fabrication plant, a hot metal forging has a mass of \mathrm{kg}$ and a specific heat capacity of 0 \mathrm{J} /\left(\mathrm{kg} \cdot \mathrm{C}^{\circ}\right) .$ To harden it, the forging is immersed in 0 .

To determine the specific heat of a new metal alloy, At a fabrication plant, a hot metal forging has a mass of \mathrm{kg}$ and a specific heat capacity of 0 \mathrm{J} /\left(\mathrm{kg} \cdot \mathrm{C}^{\circ}\right) .$ ..150 \mathrm{~kg}$ of the substance is heated to 0^{\circ} \mathrm{C}$ and then placed in a At a fabrication plant, a hot metal forging has a mass of 76 kg and a specific heat capacity of 430 J/(kg .200-\mathrm{kg}$ .At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J/(kg • °C). To harden it, the forging is immersed in 710 kg of oil that has a temperature of 32°C and a specific heat capacity of 2700 J/(kg . °C). To find the initial temperature of the forging, we can use the principle of heat transfer. The heat gained by the oil is equal to the heat lost by the forging. The equation for heat transfer is Q = m * c * ΔT, where Q is the heat transferred, m is the mass, c is the specific heat capacity, and ΔT is the change in temperature. Let's calculate:

am20 universal speaker mount for electrical box installation

SOLVED:At a fabrication plant, a hot metal forging

aluminum sheet metal work parts factory

At a fabrication plant, a hot metal forging has a mass of 75kg and a specific heat capacity of 430 J/(kg.C°). Toharden it, the forging is immersed in 710 kg of oil that has atemperature of 32 °C and a specific heat capacity of 2700J/(kg.C°).At a fabrication plant, a hot metal forging has a mass of 72 kg and a specific heat capacity of 500 J/(kg C). To harden it the forging is immerse in 840 kg of an oil that has a temperature of 32 C and specific heat capacity of 2700 J/(kg C).At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J / (kg ⋅ C ∘). To harden it, the forging is immersed in 710 kg of oil that has a temperature of 32 ∘ C and a specific heat capacity of 2700 J / (kg ⋅ C ∘).At a fabrication plant, a hot metal forging has a mass of 71.3 kg and a specific heat capacity of 427 J/(kg C°). To harden it, the forging is quenched by immersion in 717 kg of oil that has a temperature of 25.5 °C and a specific heat capacity of 2920 J/(kg C°).

At a fabrication plant, a hot metal forging has a mass of \mathrm{kg}$ and a specific heat capacity of 0 \mathrm{J} /\left(\mathrm{kg} \cdot \mathrm{C}^{\circ}\right) .$ To harden it, the forging is immersed in 0 \mathrm{kg}$ of oil that has a temperature of ^{\circ} \mathrm{C}$ and a specific heat capacity of 00 \mathrm{J .

To determine the specific heat of a new metal alloy, At a fabrication plant, a hot metal forging has a mass of \mathrm{kg}$ and a specific heat capacity of 0 \mathrm{J} /\left(\mathrm{kg} \cdot \mathrm{C}^{\circ}\right) .$ To harden it, the forging is immersed in 0 \mathrm{kg}$ of oil that has a temperature of ^{\circ} \mathrm{C}$ and a specific heat capacity of 00 \mathrm{J ..150 \mathrm{~kg}$ of the substance is heated to 0^{\circ} \mathrm{C}$ and then placed in a At a fabrication plant, a hot metal forging has a mass of 76 kg and a specific heat capacity of 430 J/(kg .200-\mathrm{kg}$ aluminum calorimeter cup containing At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J/(kg • °C). To harden it, the forging is immersed in 710 kg of oil that has a temperature of 32°C and a specific heat capacity of 2700 J/(kg . °C)..400 \mathrm{~kg}$ of water at .0^{\circ} \mathrm{C}$. To find the initial temperature of the forging, we can use the principle of heat transfer. The heat gained by the oil is equal to the heat lost by the forging. The equation for heat transfer is Q = m * c * ΔT, where Q is the heat transferred, m is the mass, c is the specific heat capacity, and ΔT is the change in temperature. Let's calculate:At a fabrication plant, a hot metal forging has a mass of 75kg and a specific heat capacity of 430 J/(kg.C°). Toharden it, the forging is immersed in 710 kg of oil that has atemperature of 32 °C and a specific heat capacity of 2700J/(kg.C°).

At a fabrication plant, a hot metal forging has a mass of 72 kg and a specific heat capacity of 500 J/(kg C). To harden it the forging is immerse in 840 kg of an oil that has a temperature of 32 C and specific heat capacity of 2700 J/(kg C).At a fabrication plant, a hot metal forging has a mass of 75 kg and a specific heat capacity of 430 J / (kg ⋅ C ∘). To harden it, the forging is immersed in 710 kg of oil that has a temperature of 32 ∘ C and a specific heat capacity of 2700 J / (kg ⋅ C ∘).At a fabrication plant, a hot metal forging has a mass of 71.3 kg and a specific heat capacity of 427 J/(kg C°). To harden it, the forging is quenched by immersion in 717 kg of oil that has a temperature of 25.5 °C and a specific heat capacity of 2920 J/(kg C°).

SOLVED: At a fabrication plant, a hot metal forging has a

At a fabrication plant, a hot metal forging has a mass of \mathrm{kg}$ and a specific heat capacity of 0 \mathrm{J} /\left(\mathrm{kg} \cdot \mathrm{C}^{\circ}\right) .$ To harden it, the forging is immersed in 0 \mathrm{kg}$ of oil that has a temperature of ^{\circ} \mathrm{C}$ and a specific heat capacity of 00 \mathrm{J .

To determine the specific heat of a new metal alloy,

.150 \mathrm{~kg}$ of the substance is heated to 0^{\circ} \mathrm{C}$ and then placed in a .200-\mathrm{kg}$ aluminum calorimeter cup containing .400 \mathrm{~kg}$ of water at .0^{\circ} \mathrm{C}$.

aluminum vs fabric mousepad

Whitehall™ Personalized Cast Metal Address plaque - LAWN MOUNTED Arch Plaque. Made in the USA. BEWARE OF IMPORT IMITATIONS. Display your address and street name. Custom house number sign.

at a fabrication plant a hot metal|Answered: At a fabrication plant, a hot metal