how to cut through metal electrical box How to Cut perfect Electrical Receptacles How to Cut Out perfect Electrical Receptacles How to Cutout perfect Electrical Receptacles How to Cut Drywall Cutti. Since the K-Factor is based on the property of the metal and its thickness there is no simple way to calculate it ahead of the first . See more

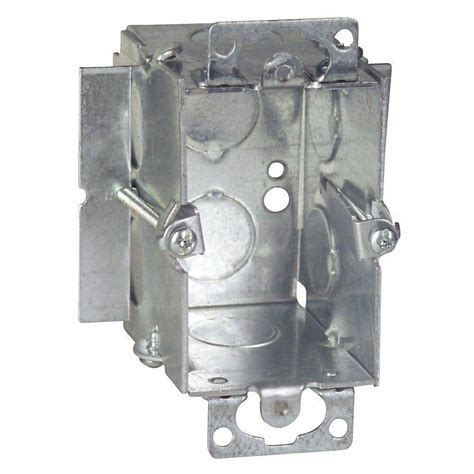

0 · steel old work gangable box

1 · steel old work electrical boxes

2 · single gang metal electrical box

3 · old work metal outlet box

4 · old work metal electrical boxes

5 · electrical metal box price list

6 · commercial electrical round metal box

7 · 1 gang steel outlet box

Precision sheet metal fabrication is a common manufacturing process that employs numerous applications and techniques to produce a wide range of consumer and commercial products. The process creates highly-accurate, .

This video shows a unique and EZ way to mark and cut out an electrical box hole in metal siding. My main tool for perfection????... How to Cut perfect Electrical Receptacles How to Cut Out perfect Electrical Receptacles How to Cutout perfect Electrical Receptacles How to Cut Drywall Cutti.Answer: Installing an electrical receptacle box using Madison Bars is a simple method for mounting gangable metal electrical boxes with ears in a wall. Need to add a cut-in box to your home? Follow these steps for cutting outlet holes in drywall to easily install an electrical box.

If plaster is attached to metal lath, cut all the way through the plaster with a knife and then cut the metal lath with side cutters. Make several passes with a sharp knife. Drill . Cut through the humped-up part of the spiral lengthwise with the cable. Unscrew the piece of spiral you just severed. If this is armored cable (AC) you will need to preserve the bonding strip to install in the box fitting for proper .

Learn how to cut an electrical back box hole in a matter of seconds with the SMART Single Box Cutter. This guide will work to remedy that by introducing you to an assortment of metal cutting methods ranging from the simplest ones utilizing hand tools all the way to more advanced methods using power tools.

rose gold filled sheet metal

An old work (retrofit) electrical box is a type of electrical box for outlets, light switches, and other devices that is installed after drywall has already been put in place. This allows you to retrofit an existing wall or ceiling without .The answer is Yes you can add holes to the back of the box with a hole saw. Hole saws and slug busters are used by Electricians regularly for this. A 7/8" hole saw will provide the correct size .This appears to be type MC cable. Obviously make sure it's turned off. Then kink the cable to separate the wraps, twist counterclockwise to further separate the metal and cut with diagonal cutters. Pull the two sections of metal cladding far . I am a little late to the party here, we have used blocking in the wall at the preferred device height, and made up wooden blocks to go behind each box, just a stack of them grab and go style, beveled on the edges to sit .

I use carbide cutters because they are a bit faster and last longer but a standard bi-metal hole saw will work with oil or cutting fluid if cut at a slow speed (full speed / no oil will will over heat the cutter and the teeth will dull quickly). Make sure to provide a little space from the wall of the box so the lock nut will fit inside the box. You don't have to get all the way through the spiral, if you get most of the way through, you'll be able to untwist to separate, or bend the cable to pull apart at the cut, and untwist. You can make the same cut the rotosplit makes with a hacksaw, but it's a little tricky holding the flexible cable in place while you make that cut. EDIT: If thick metal sometimes step bits will leave a tapered cut or if too thin when penetrating the ring you want it will pop through and the next ring will start peeling the next larger size, particularly if you are using a torquey drill. With experience you can overcome that, but for one hole a cheap hole saw should be just fine.In that case I would do like someone else suggested and tape it off and cut it out with a side grinder. Before you go cutting though I would pull the switch out and stick something like a skinny screwdriver next to the box to make sure there is even room for a two gang box. There may be a stud in the way but I guess you could always cut it.

This is my colleague Electrician Matt on-site in the real world chasing a stone wall and fitting an electrical metal back box.Training aid for how to chase a.

In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil.

using dikes, aka angled pliers,side cutting pliers , its very easy to remove a nail on box and if you are careful the nails wont get bent out of shape and it. The smaller oblong knockouts in the corners of the box have NM clamps integral with the box - no additional clamp is needed. The integral clamp is a metal clip riveted to the box that the NM cable passes under when you shove it through the knockout. The round knockouts in the middle of the box sides require the separate clamp. Electrical cut-in boxes are either metal or plastic and can come in various shapes and sizes. Shapes: Cut-ins come in different shapes based on the purpose, such as round cut-in boxes that are used for ceiling- or wall-mounted light fixtures. Round ceiling cut-in boxes are designed to hold up to 50 pounds of weight, while other types made .It has a flat, plunging blade about 1.5 inches wide, and you can buy a carbide blade that’s rated for metal-work. You can make a perpendicular plunge-cut right through the material, and you can also angle it on its edge to continue your cutting line, if you like. I LOVE mine. It’s great for cutting anywhere a circular saw can’t fit.

Use a fine-tooth metal cutting blade in your oscillating rotary tool. Begin cutting along marked lines to meet the pilot holes. Cut slowly and keep the blade perpendicular to the metal sheet. File Edges. Use a smooth metal file to deburr and smooth all cut edges. Carefully file around openings until no sharp edges remain.

0:00 Intro00:50 Testing for power1:05 Cutting out old electrical box2:26 Drilling through wall3:18 Pulling wire3:53 How to cut brick for electrical box5:27 M. 3keego Step Drills are drill bits EASY to DRILL and ENLARGE a wide range of holes on thin sheet metal. [Check Our Products Here]3keego step drill: https://3k. I'd like to install this (Manufc. Page) 20A GFCI pop-up electrical box in the kitchen floor to allow cookware (microwave, blender, air fryer) to be plugged in.I will build a kitchen island cart to house the microwave and store .

A hole was cut in a wall for a two-gang metal outlet box. The notch in the wood stud’s lower left section in the photo above accommodates the protruding screw and tab on the gangable box. I used my oscillating multi-function tool to make .

Remodel boxes (also called cut-in or old-work boxes) clamp to the drywall or plaster rather than attach to a framing member, making the work easier. However, they are only as strong as the wall surface to which they are clamped. If the drywall or plaster is damaged, cut a larger hole and install a box that attaches directly to a stud or joist . In that case there are a couple of choices. If you just want to be rid of the box you could cut off the conduit behind the box and pull the remaining stub through. A hole saw without the pilot bit could be used to cut out the center of the back wall of the box. At that point you could remove the box. –

You can drop the wire or use a fish stick to pull the wire. A new work box would probably be your best bet if you don't want to cut a sheet of drywall out. If you get a metal box, ensure you have the proper 2 hole strap to secure it. I don't use nm cable much, but it's a 1" or 3/4 knockout. I . I need to re-wire a receptacle and hope to do it without replacing the box or cutting open the wall. I have what looks like a 1995 Bakelite 20.5 cu.in. single gang box with no knockouts, nailed to the stud. The existing 14/2 cable passes through a hole with rough edges punched into the top of the box. Cut through the humped-up part of the spiral lengthwise with the cable. Unscrew the piece of spiral you just severed. If this is armored cable (AC) you will need to preserve the bonding strip to install in the box fitting for proper grounding to the metal box. Insert the red anti-short bushing to prevent the sharp metal from cutting the wire.

6. Test the fit: After cutting the electrical box hole, test the fit by attempting to insert the electrical box into the hole. Ensure that the box fits securely and flush within the framing, without any gaps or wobbling. Remember, accuracy is crucial when measuring and cutting the electrical box hole in the framing.

Are you new to box cutters? Learn how to cut an electrical back box hole in a matter of seconds with the SMART Single Box Cutter

Knockouts are the little metal discs covering the holes in the sides or back of a metal electrical box. You remove as many knockouts as you need for the number of cables that will enter the box, and leave the others in place. A box should not have open knockout holes that are empty, as this compromises the protection offered by the box enclosure.

This video shows how to cut a hole in plaster and lath for a new electrical box quickly without damaging the surrounding wall.Figure out what box you're using, u/twelveparsex listed a good one, so you know exactly what size hole to cut. Cut the larger hole so you have more space to work. You might be able to pull or cut those nails easier with the bigger hole. BTW Measure your box carefully, sometimes the hole from an existing box is to large for an old-work box to fit.

steel old work gangable box

These range from three-gang to six-gang boxes, providing space for switches, receptacles, dimmers, or combination outlets. Multi-gang boxes are used for control panels or sectioned wiring in larger rooms and commercial spaces.

how to cut through metal electrical box|steel old work gangable box