electrical metal box different size chart There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. Metal fabrication is the creation of parts, products, or structures from raw metals. This means using one or more metal fabrication processes to shape, bend, cut, or assemble metal stock into a finished or semi-finished .

0 · standard size electrical box

1 · standard electrical box size chart

2 · electrical pull box size chart

3 · electrical boxes listing and use

4 · electrical box volume chart

5 · electrical box volume calculator

6 · electrical box dimensions standard

7 · dimensions of electrical outlet box

In this guide to CNC Swiss machining, we’ll go over what you need to know to decide whether Swiss machining is best for your project. What is Swiss Machining? Originally developed to produce intricate watch parts for the Swiss watchmaking industry in the late 19th century, Swiss screw machines required a skilled operator who could turn .

Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the .

Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this .

In this guide, we will look into the applications for each subtype of electrical box. Standard Rectangular Box Best for: Compact installations in walls with single switches or .There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction. Your .

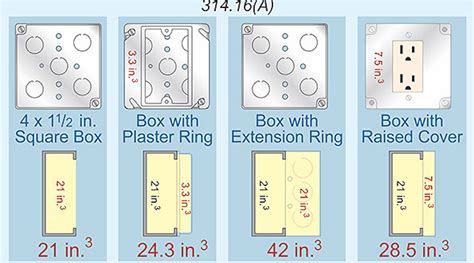

Table of Electrical Box Sizes vs Number of Wires Allowed. The electricl box size table below is an excerpt from the complete NEC Table 314.16 (A) Metal Electrical Boxes for Devices given in the U.S. National Electrical code. Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need. Metal vs. Plastic Electrical Boxes . Most electrical boxes are either metal or plastic. Metal boxes are generally steel, while plastic boxes are PVC or fiberglass. Metal Electrical Boxes . Metal electrical boxes are best for metal-sheathed cable or metal conduit. Weatherproof metal boxes for outdoor use are generally made of aluminum.Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.

standard size electrical box

In this guide, we will look into the applications for each subtype of electrical box. Standard Rectangular Box Best for: Compact installations in walls with single switches or outlets. A standard rectangular box, also known as a single-gang box, is one of the most common types of electrical boxes.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction. Your project’s construction type influences the choice of .

standard electrical box size chart

When you're installing electrical wires in a box, you need to make sure the box is big enough to accommodate them. The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Electrical boxes come in metal and plastic and in a wide range of shapes and sizes. Choosing the right size is important because it's unsafe—and illegal—to cram too many wires and devices into a box. Both plastic and metal electrical boxes are suitable for most household projects.

Table 314.16 (B) gives the volume required for each conductor of a given size. As you can see, each AWG 12 conductor required 2.25 IN3 (Cubic Inches). So, if a box has to hold the following conductors—four No. 14, four No. 12, and two No. 10 conductors—the math is pretty simple. Four No. 14 @ 2.0 IN3 = 8.0 IN3. Four No. 12 @ 2.25 IN3 = 9.0 IN3.Table of Electrical Box Sizes vs Number of Wires Allowed. The electricl box size table below is an excerpt from the complete NEC Table 314.16 (A) Metal Electrical Boxes for Devices given in the U.S. National Electrical code.

Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need. Metal vs. Plastic Electrical Boxes . Most electrical boxes are either metal or plastic. Metal boxes are generally steel, while plastic boxes are PVC or fiberglass. Metal Electrical Boxes . Metal electrical boxes are best for metal-sheathed cable or metal conduit. Weatherproof metal boxes for outdoor use are generally made of aluminum.Electrical Boxes vary in size, material, number of gangs, and shape and are designed for specific uses like junctions, outlets, and switch or fixture boxes for wiring in wall or ceiling. Use this guide to determine the best electrical box choice for your application.

In this guide, we will look into the applications for each subtype of electrical box. Standard Rectangular Box Best for: Compact installations in walls with single switches or outlets. A standard rectangular box, also known as a single-gang box, is one of the most common types of electrical boxes.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction. Your project’s construction type influences the choice of .

When you're installing electrical wires in a box, you need to make sure the box is big enough to accommodate them. The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Electrical boxes come in metal and plastic and in a wide range of shapes and sizes. Choosing the right size is important because it's unsafe—and illegal—to cram too many wires and devices into a box. Both plastic and metal electrical boxes are suitable for most household projects.

metal box man

electrical pull box size chart

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

electrical metal box different size chart|electrical box volume calculator