application of cnc milling machine CNC machining offers advantages at every stage of the automotive manufacturing process, from prototyping in Research and Development (R&D) to producing large quantities of parts. In addition, CNC milling machines and lathes make a lot of different components, from large engine block parts to small gears and panels.

CITIZEN L20X (1M10) Swiss type CNC Lathe (used) New 2011 w/LNS Express 332 mag loader w/4 channel sets, mist collector, HP Cool system, live back working all standard tooling included as well as bo.

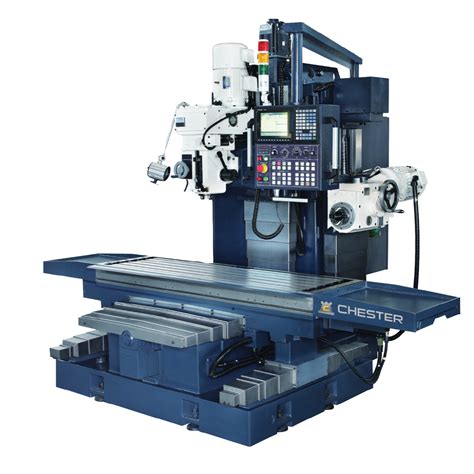

0 · types of cnc milling machines

1 · most affordable cnc milling machines

2 · cnc milling machine pdf

3 · cnc milling machine near me

4 · cnc milling machine description

5 · cnc milling machine definition

6 · best milling machine for small shop

7 · affordable cnc milling machines

Thieves and vandals don’t stand a chance against the sturdy, durable metal housing of this Charging Cabinet. Lock it securely with the included 2-piece key set and give access only to authorized personnel. Its vertically split door requires less space to open in confined areas.This connector with EASY Reversible can be plugged into the USB-C female port in both directions. DIY 24pin USB 3.1 Type C USB-C Male Plug Connector SMT type . with 3.0mm SR .

This guide comprehensively explores everything you need to know about CNC milling, from the process to how CNC milling machines work. The guide also delves into the applications, benefits, and limitations of CNC milling.

metal fabrication 98233

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.This guide comprehensively explores everything you need to know about CNC milling, from the process to how CNC milling machines work. The guide also delves into the applications, benefits, and limitations of CNC milling.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machining offers advantages at every stage of the automotive manufacturing process, from prototyping in Research and Development (R&D) to producing large quantities of parts. In addition, CNC milling machines and lathes make a lot of different components, from large engine block parts to small gears and panels.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)

Some typical applications of mill CNC machines include cabinets, furniture, prototype models, signage, and musical instruments. CNC milling machines offer high precision and versatility and can produce complex shapes that would be nearly impossible to achieve with manual machining.

CNC milling is a manufacturing process in which a computer-controlled machine tool is used to remove material from a workpiece to create a finished part. This process is very precise and allows for complex shapes to be created with ease.

CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a .

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts. CNC milling is a machining method that uses the multi-point rotary milling cutter to remove materials from the workpiece making feed motion on the CNC milling machine, to create a broad variety of features or parts. Milling is generally used to produce various flat surfaces, grooves, slots, gears, racks and other profiles. CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

This guide comprehensively explores everything you need to know about CNC milling, from the process to how CNC milling machines work. The guide also delves into the applications, benefits, and limitations of CNC milling. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machining offers advantages at every stage of the automotive manufacturing process, from prototyping in Research and Development (R&D) to producing large quantities of parts. In addition, CNC milling machines and lathes make a lot of different components, from large engine block parts to small gears and panels.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) Some typical applications of mill CNC machines include cabinets, furniture, prototype models, signage, and musical instruments. CNC milling machines offer high precision and versatility and can produce complex shapes that would be nearly impossible to achieve with manual machining. CNC milling is a manufacturing process in which a computer-controlled machine tool is used to remove material from a workpiece to create a finished part. This process is very precise and allows for complex shapes to be created with ease.

CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D CAD model converted into a .

CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a vertical milling machine is perpendicular to the worktable. It is designed for machining small components, such as molds, fixtures, and precision parts.

types of cnc milling machines

most affordable cnc milling machines

If you're looking for used Gear Hobbers machines, Machine Hub is the marketplace for you. Get free quotes from our vast network of used machinery dealers.

application of cnc milling machine|types of cnc milling machines