tig welding 18 gauge sheet metal Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. When it rains hard, I get water that comes into my breaker box, inside the grey power cable that runs into the box. The outside of the cable and the top of the box stay dry. If you follow the power feed from the top of the box, it runs outside and into the electric meter.

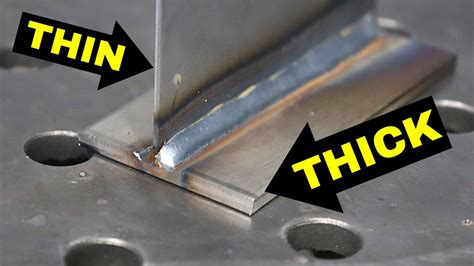

0 · welding thin to thick metal

1 · welding stainless steel sheet metal

2 · welding sheet metal without warping

3 · welding 14 gauge sheet metal

4 · tig welding stainless sheet metal

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

Read real reviews and see ratings for Washington DC, DC metal fabricators and restorers for free! This list will help you pick the right metal fabricators and restorers in Washington DC, DC.

When welding sheet metal, learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal process choices for getting the best results.

spot welding sheet metal

Tig welding 18 guage sheet. Anybody have any advice on tig welding 18 gauge steel? I can seem to do 16 gauge alright way down at 9 amps but 18 gauge is just blow through from the moment I pull the trigger.TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise . Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . I only have a harbor freight tig right now to play with. I am getting the Miller Syncrowave 200 sometime soon. I think I figured away to get a proper working pedal on the machine and should be starting it soon. Anyway while .

Exclusive, Patent Pending, Design Provides A Perfectly Beveled 45° Weld-Prepped Edge In 20 Or 18 Gauge Sheet Metal ; Proper Weld-Prepped Edges Allow Strong, Flush, Crack-Free Welds In Sheet Metal ; Each Strike Forms A Perfect 0.062” X 45° Beveled Flange ; Achieve Solid, Full-Penetration Mig Or Tig Butt Welds

Utilize filler metals (wires) that are slimmer as compared to reedy sheet metal. Numerous welders utilize 0.023-inch diameter wires and 0.024 inches for slimmer sheet metals. 18-gauge metals such as stainless steel have wire diameters of 0.030 and 0.034 inches. The Angle of the Torch. Align your torch angle to stop burnout in the SCT model.

TIG Welding Plasma Cutting Multi-Process Welding . Collet Body 17/18/26 or 9/20 Kits, Cups, Electrodes, Gas Lens, Collets Back Caps Fixture Table Show Cart. Search. Welding Machines Shop All Welding Machines . Wire & Sheet Metal Thickness Gauge for Welding

To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. . I find that just a small piece of 18 gauge sheetmetal will often do the trick and take away just enough heat so you don't blow through the panel itself. . Get a conversion kit for gas and convert that thing to MIG and forget about .Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal for welding mild steel. For the inert gas, aim at having more argon to carbon dioxide – 75% argon to 25% . 16 guage sheet metal, volt setting, tungsten size and cup size? . 16 gauge is about .060" thick. General rule for steel is 1 amp per .001" of thickness. . ↳ Metal Cutting; ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding; ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding;

Matt goes over some great tips on welding sheet metal with the TIG 200 AC/DC welder. Get the TIG 200 HERE: https://www.eastwood.com/tig200acdc.html?utm_sourc.Mild steel sheet. 18 or 20 or 22 gauge. About for a 4'*4' piece. 22 gauge for new Hondas. 18 for old vw pans. 20 gauge for old vw bodies. It's a personal preference. 22 is way easier to bend than 18, but 18 will take more weld without blowing through. The stuff I get is light gray with an oil film, but black steel would work too

TIG welding thin sheet metal with a 3/32" (2.4mm) tungsten electrode. This might be obvious to you but for tig welding really thin metal, its best to taper the electrode like a needle for the best and most crisp arc starts. (less of a taper can help with . The PRIMEWELD TIG 225X is a formidable welding machine for sheet metal work. Its dual TIG/Stick welding capability allows it to easily handle different welding tasks. The precise control over amperage, ranging from 10-225A, allows for very fine work on sheet metal, maintaining the integrity of the material. Exclusive Patent Pending Design, Which Easily Provides A Perfectly Beveled 45° Weld-Prepped Edge In 20 Or 18 Gauge Sheet Metal ; Proper Weld-Prepped Edges Allow Strong, Flush, Crack-Free Welds In Sheet Metal ; The Convenient Hole Punch Feature Provides Clean, Burr-Free 0.19” Holes ; Each Strike Forms A Perfect 0.062” X 45° Beveled Flange (I've found the 1959 panels are heavier gauge than todays vehicles) - remember also, this is a body on frame vehicle, not a structural unibody. . too hot and I've found mig welding the whole seem is a nightmare to grind cause the weld will be much harder than the sheet metal I've had some success with Tig no filler but its only ideal for all .

The continuous wire need to be rest on the joint in MIG welding. When MIG welding of thin stainless steel gauge sheet or pipes, practice to weld with high travel speed thus help you to avoid the burn through. Always keep welding amps on lower side. Choose based on .

In contrast to manual arc welding and TIG welding, MIG/MAG systems require only two adjustments to set up. . Weld 16, 20 and 25 or other Gauge Sheet Metal. Properly setting up the MIG welder is essential to .

welding thin to thick metal

It can handle different types of welding, has a durable and sturdy build, and is overall one of the best MIG and TIG welders for sheet metal on the market today. . welding guide, and material thickness gauge. . For sheet .The biggest problem with thin gauges, like 18 gauge or thinner, is the fact you need just the right amount of heat to produce complete penetration but not to burn the holes in the weld. . Although skill requirements are the highest among other welding methods, its advantages truly make TIG welding the king of sheet metal welding. MIG Welding . What's a good setup for butt welding 20 gauge mild steel sheet metal using TIG? I've got a Sychrowave 180 and the smallest collet I've got is 1/16 inch. Dan Covell has suggested elsewhere that 1/16 inch tungsten, and 0.035 inch wire will work. Can I use MIG wire instead of "real" TIG wire? The application is not too critical, it is mending the .

In this video I show you how to prepare, make and Tig weld in your own patch panel. The Tig process is my favorite process of welding. This panel is being in. In this video Matt goes over three tips for TIG welding sheet metal that will help you get the best results! BUY TIG 200 DIGITAL: https://www.eastwood.com/ti. A must for the beginning welder and professional like. Minimizes blow through and warpage when joining panels. Simply cut patch or full panel. Overlay panel over repair area, scribe and cut panel on vehicle and use the Pneumatic Weld-Prep tool to . I've made a frame for a propane tank shield from 3/8 inch steel rod, and I plasma cut 18 gauge cold rolled steel sheet for the shield itself. My initial though was to put the metal sheet outside, with the frame inside the sheet, but after playing around with it I think it will look better with the frame outside and the sheet inside the frame .

Premium quality ER308L stainless steel TIG welding rods; available diameters 0.045-inch, 1/16, 3/32 and 1/8 with 36-inch length. Package of 1-Lb, 5-Lb and 10-Lb. . For stainless sheet metal, use one size lower than you would use for carbon steel. . Metal Gauge Joint Type Tungsten Size Filler Rod Size Cup Size Argon Gas Flow @ 20 PSI (CFH .

I need to weld some 22 Gauge sheet metal with my Lincoln Easy Mig 180. Question is, does smaller wire burn hotter because there is less material going in to cool the puddle? If i look on the chart on the welder, it says to use settings 2-B for 22 gauge either .025 or .030 wire (100% co2). So if i don't change the settings between the 2 wires, won't the thinner .On this episode of Make It Kustom I show you how to butt weld thin sheet metal body panels using tig welding. This is a fender repair on a customers Fox body.

#welddotcomThis video was by special request from a viewer (arcstreams). He asked that we demonstrate some tips for welding mild steel sheet metal and some o.

welding stainless steel sheet metal

Walters Cabinets is your source for custom finishes in your home. Whether it’s your kitchen, basement, office or bathroom, we’re proud to offer custom design, quality manufacturing and seamless installation.

tig welding 18 gauge sheet metal|mig welding galvanized sheet metal