air slide junction box Junction Box, Knock-Outs, Steel, Gray, 6x6x4 In, NEMA 1, Hinged, Slotted Latch Mfr. Part #: AHE6X6X4 / RS Stock #: 70278545

From architectural applications to machine guarding, we have woven wire mesh for your application. Examples of common applications include: Woven wire mesh baskets; Woven wire mesh architectural grilles; Woven wire mesh display shelves and stands; Woven wire mesh racks; Woven wire mesh liquid filtration; Woven wire mesh air filtration; Woven .

0 · air slide inspection ports

1 · air slide conveyor problems

2 · air slide conveyor parts

3 · air slide conveyor installation

4 · air slide conveyor inspection

5 · air slide conveyor diagram

6 · air slide conveying

7 · air slide chute

NOTE: Colors showare representative of Wrisco’s prefin ished aluminum colors but not necessarily exact matches. Colors and availability subject to change without notice. ® ®

Junction boxes are part of pneumatic conveying systems. It is used to change the conveying direction of the air slides at the desired angle. As in the airslide system, pneumatic conveying .Air slide systems also called air slide conveyor / air slide chute or pneumatic fluidizing conveying systems, which widely used in cement plants for raw materials and the cement conveying, also be used in the industries of bauxite, .

air gravity conveying system uses the forces of gravity to do most of the work with no moving parts. Material is fluidized through a porous media with low pressure air. Material flow is .Air-Slide sections are available in a range of standard opening sizes up to lengths of 6 metres, but can also be manufactured to individual customer requirements, they can be joined directly .Aeration conveyors (Air Slides) are used to gravity-convey powders by passing low-pressure air through a porous membrane media and into the bed of the material being handled. You can handle a large variety of materials with .Junction Box, Knock-Outs, Steel, Gray, 6x6x4 In, NEMA 1, Hinged, Slotted Latch Mfr. Part #: AHE6X6X4 / RS Stock #: 70278545

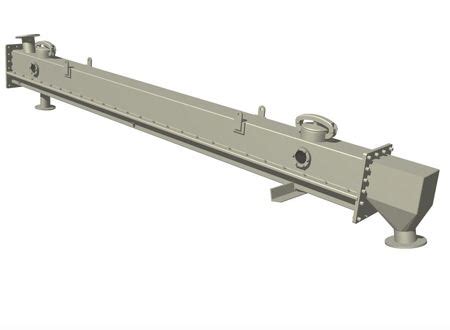

PEBCO ® Fluidized Conveying equipment (commonly referred to as “air slides”) transports materials that can be fluidized by aeration, such as cement, fly ash, alumina, etc. PEBCO ® air slides are optimal for fluidized transport.FLSmidth's Airslide fluidized conveying systems harness the power of gravity, giving you a system that is low maintenance, high efficiency and high performance. Through effective fluidization technology, throughputs of more . Understanding how air slide conveyor systems work. Knowing the basic airslide conveyor system features. Some of the basic structural features of an air slide conveyor system include: Section width and height of the aeration bed dictates the conveying rate; Turning boxes (pots) are used to divert flow from one direction to another.

Junction boxes are part of pneumatic conveying systems. It is used to change the conveying direction of the air slides at the desired angle. As in the airslide system, pneumatic conveying is provided by the polyester fiber. It can be manufactured in different .Air slide systems also called air slide conveyor / air slide chute or pneumatic fluidizing conveying systems, which widely used in cement plants for raw materials and the cement conveying, also be used in the industries of bauxite, CaCO3, carbon black, gypsum, flour and other industries for powders or small particles (diameter < 4mm) conveying.air gravity conveying system uses the forces of gravity to do most of the work with no moving parts. Material is fluidized through a porous media with low pressure air. Material flow is achieved by sloping the Airslide conveyor to match the fluidized angle of repose of the powdered material. At the correct slope, fluidized

air slide inspection ports

Air-Slide sections are available in a range of standard opening sizes up to lengths of 6 metres, but can also be manufactured to individual customer requirements, they can be joined directly together or incorporate any of the Pneuvay standard Air-Slide accessories (see below) to suit your needs. Standard Air-Slide ModelsAeration conveyors (Air Slides) are used to gravity-convey powders by passing low-pressure air through a porous membrane media and into the bed of the material being handled. You can handle a large variety of materials with aeration conveyors .

Junction Box, Knock-Outs, Steel, Gray, 6x6x4 In, NEMA 1, Hinged, Slotted Latch Mfr. Part #: AHE6X6X4 / RS Stock #: 70278545

PEBCO ® Fluidized Conveying equipment (commonly referred to as “air slides”) transports materials that can be fluidized by aeration, such as cement, fly ash, alumina, etc. PEBCO ® air slides are optimal for fluidized transport.

FLSmidth's Airslide fluidized conveying systems harness the power of gravity, giving you a system that is low maintenance, high efficiency and high performance. Through effective fluidization technology, throughputs of more than 2000 m3/h are possible with very low energy consumption.

We are the best manufacturer of Air slide distribution box/ Diverter gate / Air Slides (Fluid Slide) is used for handling Fine, Dry material like cement, Ash, Dust, and Powder etc. We provide these Aeration Conveyors in order to fulfill the need of every production industries. Understanding how air slide conveyor systems work. Knowing the basic airslide conveyor system features. Some of the basic structural features of an air slide conveyor system include: Section width and height of the aeration bed dictates the conveying rate; Turning boxes (pots) are used to divert flow from one direction to another.Junction boxes are part of pneumatic conveying systems. It is used to change the conveying direction of the air slides at the desired angle. As in the airslide system, pneumatic conveying is provided by the polyester fiber. It can be manufactured in different .

Air slide systems also called air slide conveyor / air slide chute or pneumatic fluidizing conveying systems, which widely used in cement plants for raw materials and the cement conveying, also be used in the industries of bauxite, CaCO3, carbon black, gypsum, flour and other industries for powders or small particles (diameter < 4mm) conveying.air gravity conveying system uses the forces of gravity to do most of the work with no moving parts. Material is fluidized through a porous media with low pressure air. Material flow is achieved by sloping the Airslide conveyor to match the fluidized angle of repose of the powdered material. At the correct slope, fluidizedAir-Slide sections are available in a range of standard opening sizes up to lengths of 6 metres, but can also be manufactured to individual customer requirements, they can be joined directly together or incorporate any of the Pneuvay standard Air-Slide accessories (see below) to suit your needs. Standard Air-Slide Models

Aeration conveyors (Air Slides) are used to gravity-convey powders by passing low-pressure air through a porous membrane media and into the bed of the material being handled. You can handle a large variety of materials with aeration conveyors .Junction Box, Knock-Outs, Steel, Gray, 6x6x4 In, NEMA 1, Hinged, Slotted Latch Mfr. Part #: AHE6X6X4 / RS Stock #: 70278545PEBCO ® Fluidized Conveying equipment (commonly referred to as “air slides”) transports materials that can be fluidized by aeration, such as cement, fly ash, alumina, etc. PEBCO ® air slides are optimal for fluidized transport.

FLSmidth's Airslide fluidized conveying systems harness the power of gravity, giving you a system that is low maintenance, high efficiency and high performance. Through effective fluidization technology, throughputs of more than 2000 m3/h are possible with very low energy consumption.

air slide conveyor problems

wholesale cnc turning parts suppliers

wholesale cnc metal part

wholesale cnc mechanical parts suppliers

air slide conveyor parts

$5.99

air slide junction box|air slide conveying