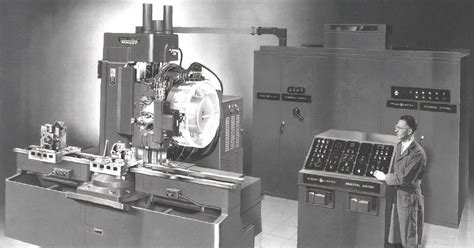

cnc machining in the 1960s The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s. As computing technology advanced, CNC systems . $17.99

0 · who invented cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of precision machining

4 · history of cnc technology

5 · history of cnc machine pdf

6 · cnc machine history timeline

7 · cnc machine background

Carry your favorite soup or even oatmeal in this modern stainless steel food jar from Thermos. It has double-wall vacuum insulation to keep meals hot or cold and comes with an ergonomically designed foldable spoon for added convenience.

In the 1960s and 1970s, the introduction of computers to control the machine tools was a game-changer. The advent of microprocessors and digital technologies in the 1980s further accelerated the development of CNC machines, making them more powerful, versatile, and easier to use. In the mid-1960s, numerical control (NC) using transistor technology was introduced. Then, in 1966, integrated circuits helped NC become a more compact, realistic .The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s. As computing technology advanced, CNC systems . The 1960s witnessed a significant evolution in CNC machining with the introduction of computer control. This transition from Numerical Control (NC) to Computer Numerical Control (CNC) represented a leap in the .

During the 1960s and 1970s, computer technology moved fast enough and was reliable enough for machine shops to begin adopting CNC machines instead of using the older NC systems. Without punch cards that . The 1960s saw the introduction of the first CNC lathes, which were capable of producing highly accurate and repeatable parts.The 1960s brought significant advancements in digital control systems for CNC machines. The introduction of computers allowed for more sophisticated programming and control capabilities.

The first fully automated CNC machines were developed in the 1960s and 1970s. They made it possible to program detailed instructions for operating the cutting tool. That means that when it came to making parts, .Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM During the 1960s and 1970s, computer technology moved fast enough and was reliable enough for machine shops to begin adopting CNC machines instead of using the older NC systems. Without punch cards that .

who invented cnc machine

But this technology didn't appear overnight. The history of CNC machining is a long and fascinating one, filled with key developments and breakthroughs that have helped shape modern engineering and design. . Throughout the 1960s . I have a 1980 Cincinnati 207MK CNC Vertical mill, that I converted to a push button operated manual mill. Took the sum total of five hours to rip the CNC control off, and have a totally like new running manual mill.Now I know that's not the direction a big time machine tool builder like myself is suppose to go, but it was so easy to do.Study with Quizlet and memorize flashcards containing terms like What technological advance in the 1960s was responsible for dramatically increasing the use of numerical control technology?, Name two advantages of using CNC equipment instead of manual methods., How many axes of movement does a basic milling center have? and more.

For anything CNC related: CAD, CAM, automation, and more! Advertisement Coins. 0 coins. . 1960s machining vs today. . 1960's manufacturing company: It's perfectly acceptable if we kill or seriously maim 7 machinists a year, if it means we get more parts out. 2023 manufacturing company: We are willing to waste 7 mins a month if it means .The transition from manually operated machines to CNC was revolutionary. In the 1960s and 1970s, the introduction of computers to control the machine tools was a game-changer. . Modern CNC Machining. Today, CNC machining stands at the forefront of manufacturing technology, offering precision and flexibility that were unimaginable in the early .

how to set up parting tool st20 haas cnc lathe

Explore the evolution of manufacturing technology with our in-depth guide on the history of CNC machining. Uncover the key moments that shaped precision engineering. . The first fully automated CNC machines were developed in the 1960s and 1970s. They made it possible to program detailed instructions for operating the cutting tool. That means . 4. HISTORY 1955 - US Air Force define a need to develop a machine tool capable of machining complex and close tolerance aircraft parts. 1959 - MIT is the contractor and builds the machine for the project. MIT announces Automatic Programmed Tools (APT) programming language 1960 - Direct Numerical Control (DNC). This eliminates paper tape and allows . The 1960s saw the introduction of the first CNC lathes, which were capable of producing highly accurate and repeatable parts. At this time, the use of CNC machines began to spread rapidly throughout the manufacturing industry, and by the 1970s, CNC machining had become an essential tool for many industries, including aerospace, automotive, and . CNC machining is one of the most common processes used in manufacturing today. It is such an institution in the field that it can seem like it’s been around forever. In fact, the underpinnings of CNC machining have only been around for less than a century, with the more recognizable version of the technology — similar to the method still used today — coming in .

The Transition from NC to CNC: In the late 1960s and early 1970s, as computer technology advanced, . Multi-Axis CNC Machining: CNC machines with more than three axes (e.g., 4-axis, 5-axis, and . CNC Machining Machine Shops in 1960. Avalon June 28, 2023. This is a fun one. Check out this video. It’s amazing how much and how little has changed since then. CNC Machining No Comments. Avalon. Previous Post Manufacturing's Quality and Cost Paradox The most ubiqutious of the Moog models, circa 1969. Pneumatic logic control with hydraulic actuator drive. ===== Above posted in 'CNC' and 'Antique Machinery' Forums due to possible divergent groups/ perspectives inhabiting each .

10/24: Complete Machine Shop; 10/30: Carbon Fiber Wheel Manufacturer; 10/31: MRO Surplus Equipment; 10/31: Precision CNC Machinery; 11/12: New Test Kit Production Equipment; 11/13: CNC Machinery – SEiGLER REELS; 11/14: .

I swear the FANUC corporation worked their butts off in the late 20th cen making a perfectly good 32 bit computer act like a early 1960's sequencer on paper tape. I haven't crashed the machine yet, but the rate at which I'm running into crazy exceptions I will. Open source would be great. I'll spend money if I have to.I was asked to film an instructional video on how to operate a proto track cnc machine for our other branch in China. r/science • Earth's Population Will Begin Shrinking Within 50 Years, Scientists Predict Learn what CNC machining is and unlock the secrets of precision manufacturing. Uncover the technological marvels that drive manufacturing excellence in every detail. . Development of the first CNC machine: 1960s: Development of CAD and CAM software: 1970s: Adoption of digital computers for controlling NC machines: 1980s: Introduction of PCs . The commercialization of CNC machines gained momentum in the 1960s, making these cutting-edge technologies more accessible to manufacturers. With advancements in microprocessors and computer technology in the 1970s, CNC machines became more compact, affordable, and powerful. . CNC machine programming plays a crucial role in turning CAD .

Engineers apply the knowledge of math & science to design and manufacture maintainable systems used to solve specific problems. AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines. Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. . Known mostly for sweeping cultural and political change, the 1960s also were shaped heavily by machining technology.

The development of CNC machining technology continued throughout the 1960s and 1970s, with the development of more powerful computers and more sophisticated software. As technology advanced, CNC machining became increasingly popular, and its use spread from the aerospace and defense industries to the automotive and manufacturing industries. This video shows the 1960 state of the art in CNC work. The setup and machining times must have been impressive back then, but laughably slow compared to today. I wonder how much a programmable turret lathe or mill cost back in the day.

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. .

Historical Development of CNC Technology. Early numerical control systems were developed in the 1950s and became commercially available in the 1960s and '70s.

A CNC machine is an automatic power tool with computer controlled for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. . In the 1960s, the TRUMPF Group began to get involved in the laser field, and in the 1980s created an industry-leading laser. Trumpf Group once invested .cnc machining in the 1960s. Processing technology: Turning,Milling,Planing,Grinding,Drilling,Etching / Chemical Machining: Heat treatment: Annealing, Normalizing , Nitriding, Tempering , Carbonitriding: Material

when were cnc machines invented

how to sew stretchy metallic fabric

how to start a cnc machine

Key Holder for Wall | Metal Key Holder Hooks Organizer Rack | Metal Key Organizer Wall Decorative with 7 Hooks for Entryway, Front Door, Hallway, Kitchen, Office (12 Inches, Mountain)

cnc machining in the 1960s|history of cnc technology