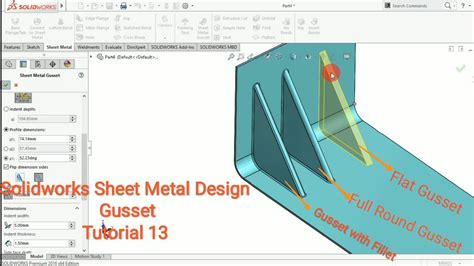

sheet metal gusset forming Welcome to our SolidWorks Sheet Metal tutorial! In this video, we dive into the Forming Tool and Gusset commands, essential for creating complex and robust s. Weatherproof electrical boxes withstand rain, snow, moisture, and outdoor elements. Electricians and contractors use these boxes to protect wiring and electrical devices in outdoor installations.

0 · solidworks sheet metal gusset

1 · sheet metal pattern layout methods

2 · sheet metal gusset forming tool

3 · sheet metal gusset design guidelines

4 · sheet metal design guidelines pdf

5 · sheet metal design guide pdf

6 · sheet metal bracket design guidelines

7 · sheet metal basic design guidelines

Find Metal Enclosure electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

Sheet metal gussets are formed with special tooling which has a ridge going across the v opening. The punch is split to the left and right of the ridge as to not be damaged while forming. The sheet metal is bent normally across the v . Stamping 2 gussets into sheet metal at VeriForm. One and a half inch spacing center to center 5/16 width of the gusset and then add material thickness to get the outside width of the gusset.

Gusset a Sheet Metal Bend. It is quite common to find a gusset of sorts in the corner (bend region) of sheet metal parts to stiffen the part. To accomplish this, we'll create a . A sheet metal gusset is an indented feature that forms a gusset to stiffen a bend in sheet metal part. Rather than using a custom-made forming tool, SOLIDWORKS includes a Sheet Metal Gusset tool. In this tutorial, we'll take a . Welcome to our SolidWorks Sheet Metal tutorial! In this video, we dive into the Forming Tool and Gusset commands, essential for creating complex and robust s.

In this issue, we cover design guidelines that can help optimize features such as gussets and extruded holes in a sheet metal forming process. Specific guidelines such as Minimum .Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of the we will learn sheet metal basic features like Base flange, Edge Flange, sheet metal gusset , hole wizard and Extruded Cut in Solidworks sheet metal.1)Solidwo.

Sheet metal gussets are provided to avoid unbending the Sheet metal part under load conditions.In this video, we will learn how to design a gusset in Creo pa. A sheet metal gusset is an indented feature that forms a gusset to stiffen a bend in sheet metal part. Rather than using a custom-made forming tool, SOLIDWORKS includes a Sheet Metal Gusset tool. In this tutorial, we'll take a look at how to create a gusset in a sheet metal part using the Sheet Metal Gusset tool.I've decided to go with a sheet metal housing with some wooden accents. I uploaded my CAD file to PCB-Way for a cost evaluation and they want to charge me for a file that requires three bends. That sounds rediculous to me? Am I so far out of this industry that I'm simply naive, or am I being ripped off? The model is ca. 150mm x 120mm and .

Forming tools can't intersect bends, the two must always be separated. The only exception is the feature called "Sheet Metal Gusset" but I doubt that is what you're looking for here. The reason most forming tools don't go across the bend region is due to the tooling required. Bending a flat surface is easy with standard tooling, but bending .

solidworks sheet metal gusset

Learn how to build sheet metal parts and associated drawings using SOLIDWORKS CAD software. Prerequisite: SOLIDWORKS Essentials Estimated time to complete: 12-20 hours. . Lesson 6: Exercise - Forming and Gusset. Lesson 6 Quiz. 8 Lesson 7 Advanced Sheet Metal Lesson 7: CrossBreak and Vent. Lesson 7: Process Plan. Lesson 7: Tab and Slot.45° gussets shouldn’t be designed to be more than 4 times material thickness on their flat edge; For holes, the distance between the gusset and the hole’s edge should be at least 8 times material thickness. Hems. Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . Specifies a linear value from the inside of the sheet metal part to the point on the y axis where the gusset intersects the sheet metal body. a1: Section profile angle dimension . Finally, we have gusset tooling for adding gussets to bent sheet metal parts. . What kind of standard press brake tooling is available for forming sheet metal parts? The standard press brake tooling available at Approved Sheet Metal includes options such as 90-degree bending for different gauge ranges, thin tip punches, narrow punches .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. . characterized by a double bend forming a Z-shape, are common in creating tiers in sheet metal or fabricating brackets and clamps. . Gussets offer a practical solution to enhance the . Hello guys, I'm having difficulty in creating a dart in sheet metal. My reference to a dart is a strenghtening crease to a right angled wall. There are no pre-defined form features of this sort in the library. Is there an easy way to generate one. T I A SW 2005 sp4

Last updated on January 29th, 2024 at 12:53 pm. At Approved Sheet Metal, our sheet metal fabrication experts fabricate brackets for product developers across the country that design for a broad range of commercial, and military applications. In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore .

Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal . Bead tool is used to create an embossed or engraved bead on sheet metal part using single entity or a set tangentially connected entities.Gussets are rib l.Sheet Metal Gusset; Exercise 18: Forming Tool; Exercise 19: Sheet Metal Gusset; Lesson 7: Additional Sheet Metal Functions. Additional Sheet Metal Functions; Cross-Breaks. Cross Break Settings; Vent Features; Mirror Part; Tab and Slot; .

Welcome to our SolidWorks Sheet Metal tutorial! In this video, we dive into the Forming Tool and Gusset commands, essential for creating complex and robust s.Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset. Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product. Posted: August 16, 2018. . Clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce, more attractive for the final customer and, most important .We are the metal forming experts not afraid to take on tough challenges like exotic metal forming or complex bends, gussets and rib forming. If you’re looking for complex bending and forming, that other metal forming companies have said can’t be done, talk to the metal forming technical staff at Northeast Laser.

Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.Many companies, particularly in the aerospace market, use Flexform™ to form the majority of their sheet metal production parts. Fluid cell forming is perfectly suited to the relatively low-volume requirements of commercial, military and business aircraft.

To open this dialog box: With a part, assembly, or drawing open, click Tools > Options > Document Properties > Sheet Metal.. To show bend lines in flat patterns, do one of the following: Click View > Hide/Show > Sketches.; In the FeatureManager design tree, expand Flat-Pattern and Flat-Pattern(n).Right-click Bend-Lines and click Show.Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . Specifies a linear value from the inside of the sheet metal part to the point on the y axis where the gusset intersects the sheet metal body. a1: Section profile angle dimension .Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

sheet metal pattern layout methods

$10.48

sheet metal gusset forming|sheet metal gusset forming tool