best steel for sheet metal bending While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to .

Effective methods of improving WiFi signal in steel-framed buildings include the application of mesh networks, the installation of WiFi repeaters, and proper placement and orientation of the router away from metal objects and appliances.

0 · thickest aluminum sheet metal bending

1 · can you bend 6061 aluminum

2 · can 6061 aluminum be bent

3 · best aluminum grade for bending

4 · bending 6061 t6 aluminum sheet

5 · bending 6061 aluminum tubing

6 · bending 3003 aluminum sheet metal

7 · 6061 t6 aluminum bending chart

$98.07

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Q235 and Q345 are 16 Mn steel grade with good formability and weldability .

building a single step with a metal bracket

Steel (both carbon steel and stainless steel) is one of the most commonly used materials for sheet metal bending due to its excellent strength, durability, and versatility. While carbon steel is more affordable, stainless steel . Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common . In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. .

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to .

building a metal house reddit

Q235 and Q345 are 16 Mn steel grade with good formability and weldability properties. It’s commonly used for structural applications and parts for a variety of industries. Q345 offers better performance at low temperatures and offers . What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending .Commonly used metals include aluminum, stainless steel, copper, brass, and mild steel, each bringing its unique properties to the table. Aluminum is prized for its lightweight and corrosion resistance, making it ideal for automotive and . Have you ever wondered how to achieve perfect sheet metal bends? This article dives into essential bending techniques, exploring everything from calculating material expansion to selecting the right tools. You’ll learn .

build your own 5 axis cnc machine

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.

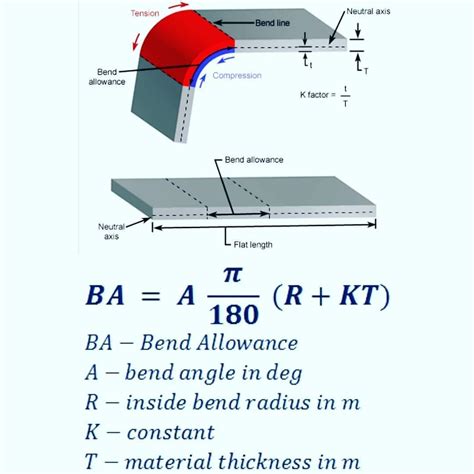

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Steel (both carbon steel and stainless steel) is one of the most commonly used materials for sheet metal bending due to its excellent strength, durability, and versatility. While carbon steel is more affordable, stainless steel has better corrosion resistance, making it ideal for more demanding applications. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to some very high-strength materials such as Hardox ®.

Q235 and Q345 are 16 Mn steel grade with good formability and weldability properties. It’s commonly used for structural applications and parts for a variety of industries. Q345 offers better performance at low temperatures and offers better steel strength. Advantages: Disadvantages. Commonly used for:

What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending height, hole margins, bending line position, and the importance of positioning holes.Commonly used metals include aluminum, stainless steel, copper, brass, and mild steel, each bringing its unique properties to the table. Aluminum is prized for its lightweight and corrosion resistance, making it ideal for automotive and aerospace industries.

thickest aluminum sheet metal bending

can you bend 6061 aluminum

Have you ever wondered how to achieve perfect sheet metal bends? This article dives into essential bending techniques, exploring everything from calculating material expansion to selecting the right tools. You’ll learn how to tackle common challenges, ensuring high-quality, efficient production.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

can 6061 aluminum be bent

Steel (both carbon steel and stainless steel) is one of the most commonly used materials for sheet metal bending due to its excellent strength, durability, and versatility. While carbon steel is more affordable, stainless steel has better corrosion resistance, making it ideal for more demanding applications. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to some very high-strength materials such as Hardox ®.

Q235 and Q345 are 16 Mn steel grade with good formability and weldability properties. It’s commonly used for structural applications and parts for a variety of industries. Q345 offers better performance at low temperatures and offers better steel strength. Advantages: Disadvantages. Commonly used for: What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending height, hole margins, bending line position, and the importance of positioning holes.

Commonly used metals include aluminum, stainless steel, copper, brass, and mild steel, each bringing its unique properties to the table. Aluminum is prized for its lightweight and corrosion resistance, making it ideal for automotive and aerospace industries.

build your own metal frame house

build your own cnc machine quotes

Metal Box Remastered. 4 Disc Super-Deluxe Edition includes rare and unreleased mixes, B-sides, BBC sessions and the Manchester concert from June 1979 plus 72 page booklet, exclusive poster and set of art-prints.

best steel for sheet metal bending|can 6061 aluminum be bent