cnc machine fixtures 4in by 20in In this guide, the aim is to delve deep into the design, types, and uses of CNC fixtures. The topic brings to light how CNC fixtures bring precision and efficiency to the world of machining. One will gain deep insight into the . Here's how to get your new parts: Send the make model and year of your car. The .

0 · workholding fixtures for machining

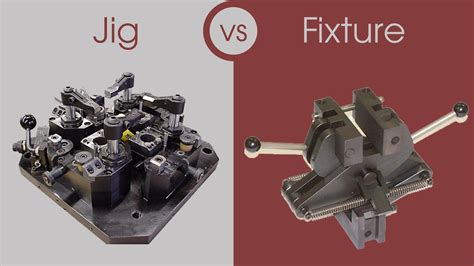

1 · types of fixtures and jigs

2 · tapped table fixture cnc machine

3 · list of jigs and fixtures

4 · jigs and fixtures for cnc

5 · holding fixtures for cnc machines

6 · fixture plates for cnc mills

7 · fixture plate for milling machine

$16.02

SMW Fixture Plates. CNC Mill Fixturing & Tooling Plates for HAAS, Brother, Tormach, Fanuc and moreFixture & tooling plate for Tormach 1100, 1100M, and 1100MX CNC machines .10.44" x 7.95" x 0.48" 6061 Aluminum Fixture & Tooling Plate for Carbide3D .The most efficient 4th Axis CNC Fixtures and Workholding: Maximize the efficiency of your CNC vertical machining center with a Stallion Trunnion Table. Made for any machine tool, rotary .

In this guide, the aim is to delve deep into the design, types, and uses of CNC fixtures. The topic brings to light how CNC fixtures bring precision and efficiency to the world of machining. One will gain deep insight into the .SMW Fixture Plates. CNC Mill Fixturing & Tooling Plates for HAAS, Brother, Tormach, Fanuc and more

In this guide, we will provide an overview of CNC fixture design and offer tips on how to create effective fixtures for your machining projects. We’ll discuss the different types of fixtures and their uses, as well as best practices for designing and testing your fixtures.The most efficient 4th Axis CNC Fixtures and Workholding: Maximize the efficiency of your CNC vertical machining center with a Stallion Trunnion Table. Made for any machine tool, rotary table, and vise.

sheet metal process information

In this guide, the aim is to delve deep into the design, types, and uses of CNC fixtures. The topic brings to light how CNC fixtures bring precision and efficiency to the world of machining. One will gain deep insight into the fixtures' indispensable role in CNC machining. Basics of CNC Fixtures! Proper positioning is key in CNC fixtures. CNC fixtures are essential in modern machining operations enhancing production efficiency and machining precision. Furthermore, using CNC fixtures allows you to churn out multiple identical parts to high accuracy useful in mass production.Custom CNC Fixtures by AME. Leverage AMROK® expertise as a turn-key workholding resource. Improve your machining processes with engineered dedicated manual fixtures, or fully automated hydraulic fixtures built from the ground up.Looking for a custom dedicated fixture or a modular workholding solution? Let an AMROK expert be your guide. Designed, manufactured, inspected, and serviced in the USA.

CNC milling or turning fixtures are common in devices or workpieces that are used in manufacturing to resist large cutting forces, hold and position the piece, guide the tool when cutting, make sure operation goes smoothly, and produce continuous exchangeability and convenience in parts. Make the right choice for your CNC fixture needs with our expert guide. Discover the different types and get tips on how to choose the best one for your project. Selecting a CNC fixture or clamp should consider the types of CNC machining center, precision requirements, batch size, processing cost and more factors.SMW Fixture Plates. CNC Mill Fixturing & Tooling Plates for HAAS, Brother, Tormach, Fanuc and more

In this guide, we will provide an overview of CNC fixture design and offer tips on how to create effective fixtures for your machining projects. We’ll discuss the different types of fixtures and their uses, as well as best practices for designing and testing your fixtures.

The most efficient 4th Axis CNC Fixtures and Workholding: Maximize the efficiency of your CNC vertical machining center with a Stallion Trunnion Table. Made for any machine tool, rotary table, and vise.

In this guide, the aim is to delve deep into the design, types, and uses of CNC fixtures. The topic brings to light how CNC fixtures bring precision and efficiency to the world of machining. One will gain deep insight into the fixtures' indispensable role in CNC machining. Basics of CNC Fixtures! Proper positioning is key in CNC fixtures. CNC fixtures are essential in modern machining operations enhancing production efficiency and machining precision. Furthermore, using CNC fixtures allows you to churn out multiple identical parts to high accuracy useful in mass production.Custom CNC Fixtures by AME. Leverage AMROK® expertise as a turn-key workholding resource. Improve your machining processes with engineered dedicated manual fixtures, or fully automated hydraulic fixtures built from the ground up.Looking for a custom dedicated fixture or a modular workholding solution? Let an AMROK expert be your guide. Designed, manufactured, inspected, and serviced in the USA.

CNC milling or turning fixtures are common in devices or workpieces that are used in manufacturing to resist large cutting forces, hold and position the piece, guide the tool when cutting, make sure operation goes smoothly, and produce continuous exchangeability and convenience in parts.

Make the right choice for your CNC fixture needs with our expert guide. Discover the different types and get tips on how to choose the best one for your project.

workholding fixtures for machining

The new RFB2 Series Floor Box can be installed in both concrete and wood floor applicatons. Provides the first recessed wood floor box for both commercial and residential applications. New lightweight "slab-on-grade" version.

cnc machine fixtures 4in by 20in|fixture plates for cnc mills