sheet metal bending maximum thickness Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . %PDF-1.4 %Çì ¢ 5 0 obj > stream xœ+T0Ð34R0A #9—K?È\!½˜« È3³06VÐ5±4µrÀ”¥‘ž¥¡ D™.‚K>W $q ñendstream endobj 6 0 obj 61 endobj 12 0 obj .

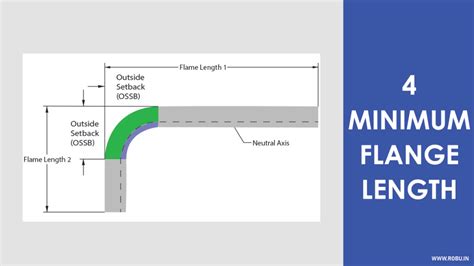

0 · sheet metal minimum flange length

1 · sheet metal minimum bend length

2 · sheet metal gusset design guidelines

3 · sheet metal bending radius chart

4 · sheet metal bending angle chart

5 · sheet metal bend tolerance chart

6 · sheet metal bend chart

7 · minimum bending radius sheet metal

$259.95

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .Thickness Limitations – A rule of thumb in sheet metal bending is that thicker materials have higher bend radiuses (“Designing Sheet Metal Components Using Laser Cutting and CNC . The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, . While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to .

Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet metal ( at least equal to sheet thickness). 2. Proper spacing . Selecting the appropriate sheet thickness is a pivotal step in sheet metal fabrication. This choice influences a variety of factors including the part's overall strength, weight, and integral design features such as minimum bend .

The flat pattern requires prediction of how the material will behave as it is bent. Kerf is the air gap left behind by the cutting tool. Punching requires a kerf width that is equal to the material thickness. A reader recently asked for . This article explores the essential formulas and guidelines for determining the minimum and maximum bending dimensions, ensuring precision in your metalworking projects. By understanding these calculations, you can .Width refers to the maximum bend length the press can achieve. A typical brake press, for example, could be 100T x 3m . Note that the term ‘sheet metal’ is typically used to refer to materials that are under 3mm in thickness. Sheet . While sheet metal thickness/gauge number has a corresponding weight ratio, such as lbs per square foot or kilograms per square metre, sheet metal sizes are not tied to the thickness. This means you may purchase an 18 .

What is the maximum thickness sheet metal one can reasonably bend by hand? Hi, I am trying to make a mount for a power strip on a desk out of either steel (low carbon/mild) or aluminum (6061). I will need to make a 45 degree and 90 degree bend similar to the image linked below.

sheet metal minimum flange length

Is there a limit to thickness of sheet metal you can bend? Our bending capabilities cover a range of sheet metal thicknesses. For specific thickness limits, please refer to our bending resources or contact our team for guidance. . The maximum thickness depends on the material, and material thickness. Materials such as 6061 and 7075 Aluminum . What is the maximum sheet metal bending thickness? 1 Answer Lukasz Siwiec. Answered on 18 Mar, 2015 01:52 PM Maximum Bend Deduction (Per Bend) = (bend Bend Radius + Part Thickness) * 2. Share Share this awesome question with your friends. Social. Copy link. 1 Answers. 0 Followers. 697 Views. Details Created: Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . The primary tool used in sheet metal bending is the brake, which is used in different forms. Cornice brake helps to clamp the metal sheet and creates a crease through force; press brake comprises of die and punch, which helps to give shape to the sheet; box and pan brake helps give numerous bend lines, and for this, they use finger like metal .

Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm).

The force required to bend sheet metal increases with bend length, external bend angle and sheet metal thickness, and it decreases with increasing bend radius. Sheet metal fabricator Hydram’s pressbrakes have varying capabilities and maximum bend length of 4 metres and a maximum force of 250 tonnes are available. The table below illustrates .

This approach enables more precise control over the sheet metal bending process. Consider Additional Bending Parameters: Apart from the K-factor, take into account other factors such as bend radius, bend angle, and part thickness. These parameters work together to determine the best practices for sheet metal bending.

sheet metal minimum bend length

sheet metal gusset design guidelines

sheet metal bending radius chart

In understanding sheet metal bending, this article introduced how to bend sheet metal and other things ideal for effective execution. . Moreover, the maximum thickness of metal sheets that can be formed varies depending on the material type. For instance, aluminum, with its higher formability, can be shaped into thicker sheets than titanium . Ever wondered how to calculate the bending limits of sheet metal accurately? This article explores the essential formulas and guidelines for determining the minimum and maximum bending dimensions, ensuring precision in your metalworking projects. . Material thickness t: 1.0: 1.2: 1.5: 2.0: 2.5: 3.0: 4.0: 5.0: Lmax: 60: 60.2: 60.5: 61:

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. . Thickness Minimum Bend Bend Radius Min Flange Min Hole.020_1075 Annealed Spring Steel (0.02" | 0.51mm ) 0.75" | 19.05mm: 0.605" | 15.37mm: 0.75"

Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with 700N/mm 2 tensile strength (stainless steel); There are four primary hemming bending solutions designed to accommodate various bending .

The space between the final set of rollers determines the final metal thickness. After the desired thickness is obtained, the sheet metal then is rolled into a large coil. Typical sheet metal thicknesses used in stamping are 0.001 .Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . times the material thickness + bend radius from the bend itself. Slot-to-form-long slots should be spaced 4 X the material thickness plus the bend radius. - 12 -Study with Quizlet and memorize flashcards containing terms like 1. Sheet metalworking includes both forming and cutting operations: (a) True or (b) false?, 2. Typical sheet-metal thicknesses are between 0.4 mm (1/64 in) and 6 mm (1/4 in). When thickness exceeds the upper limit of this range, the stock is usually referred to as which one of the following: (a) bulk stock, (b) .

Then you can use the thickness of the sheet and the radius to see how much strain is on the outside of the sheet at a given radius. Keep the strain on the outside lower than the yield and it should stay in the elastic region. Sheet metals are very versatile and widely employed in various manufacturing methods including bending and folding. Sheet metal forming is relatively less expensive as compared to other machining operations employed in manufacturing metal blocks. . Table 6 illustrates the maximum thickness for bending and folding applications based on the . Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing .

The data in the table above is the preferred data for reference only. In fact, the rounded corners of press brake are usually 0.3, and a small number of the rounded corners of the press brake punch is 0.5.. For ordinary low carbon steel plate, anti-rust aluminum plate, yellow copper, purple copper etc, the inner radius 0.2 is no problem, but for some high carbon steel, .

A hem bend is an edge of sheet metal that is bent 180 degrees and flattened on top of itself. Protocase Tech Tip Video . including aluminum, cold rolled steel, galvanneal and stainless steel, so long as the material doesn’t exceed the maximum thickness. Material Maximum Material Thickness; Aluminum: 0.051” (1.295mm) Cold Rolled Steel: 0. .Sheet Metal Bending Guide At GA Industries we use the air bending process to form flanges on sheet metal parts. Air bending . Thickness (A): Nominal material thickness IR (B): Inside radius Maximum Length of Bend: Maximum distance of bend across the part Minimum Flange Length (C): Minimum length of flange to bend without issues .

hardy junction box

In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness.

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”. We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. . Sheet metal thickness often has slight variations compared to its stated gauge thickness. For example, a 16-gauge cold-rolled steel sheet may have a stated thickness of 0.057 .Thickness. Hemming is usually performed on thicknesses ranging from a minimum of 0,6 - 1,5 mm. Naturally, the thicker the sheet metal, the more bending force must be applied. The maximum thickness for hemming is 3 mm. With such thickness, hemming is used to reinforce the material, rather than making edges safer to handle.

hardware to hold straps on metal boxes

Stopping in a yellow box junction could cost you up to £130. We explain the rules, so you can stay safe and avoid a fine. A study by the RAC has uncovered problems with 90 percent of proposed.

sheet metal bending maximum thickness|sheet metal minimum bend length