sheet metal tolerance chart in mm These tolerances are recommended and best practices. We can obtain tighter tolerances (depending on part geometry/ construction), so feel free to contact us for more information or . Explore & source all the CNC replacement parts you need to keep your machine in .

0 · typical sheet metal tolerances

1 · tolerance for sheet metal thickness

2 · steel plate thickness tolerance chart

3 · standard sheet metal tolerances chart

4 · sheet metal thickness tolerance chart

5 · sheet metal stamping tolerances

6 · galvanized steel sheet thickness tolerance

7 · 12 ga steel sheet thickness

In the wholesale world, the pricelist for Brass CNC turned part hinges on several factors, ranging from production complexity and raw materials cost to market demand and order volume. Raw .

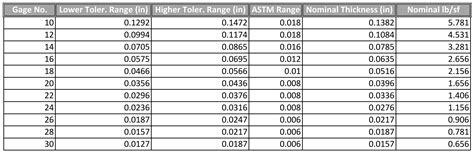

Sheet Metal & Wire Gauge Sizes Data Chart. Tolerances, Engineering Design & Limits & Fits.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .Tolerances: Sheet metal tolerances should not be tighter than necessary to make . The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

These tolerances are recommended and best practices. We can obtain tighter tolerances (depending on part geometry/ construction), so feel free to contact us for more information or . Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from .

Steel Sheet Thickness Tolerances.xls. Weight equivalents based on density of .2904 lb. per cubic inch. Cold rolled gages 4 through 10 tolerances shown for widths over 48" to 72" inclusive. Hot .

Sheet Metal Gauge Chart. Sheet metal thickness is denoted by gauge, sometimes spelled gage, which indicates a standard thickness before processing. Click here for a Gauge . Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical . We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Sheet Metal Part Design for Manufacturing Tip. DESIGNING .The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the .

Sheet Metal Gauges. The below table summarizes sheet metal gauge and tolerances. Monroe, nor any of its employees shall be held liable for any improper or incorrect use of the .Recommended Default Sheet Metal Tolerances Default Tolerances (Millimeters) DIM Tolerance Description A ± 0.13 Sheared Edge to Hole B ± 0.13 2 Holes on One Surface C ± 0.25 Formed Edge to Hole D* ± 0.76 Holes Across 2 Bends E* ± 0.76 Holes Across 4 Bends F ± 0.25 Sheared Edge to Bend .Know the steel sheet metal gauge chart in inch and mm, also find the durability and best tool to measure sheet metal thickness. 0 About Us; Products; Price list; . The thickness tolerance of a stainless steel sheet depends on the chosen .The sheet metal does however have a tolerance on the rolling thickness which needs to be taken into account when designing a tight fitting assembly, especially as the sheet metal material gets thicker. . 1000 mm wide sheet metal: 1250 mm wide sheet metal: Group I: Group II: Group I: Group II: 0.61 to 0.80: 0.03: 0.04: 0.06: 0.07: 0.81 to 1.00 .

3 Sheet Metal Part Design for Manufacturing Tip. 3.0.1 DESIGNING FEATURES TOO CLOSE TO THE BEND; 4 A Note on Tolerance Stack-Ups; 5 Precision Sheet Metal Tolerance FAQ. 5.0.1 Why is tolerancing in precision sheet metal fabrication more complex than in precision machining? 5.0.2 What are the variations in sheet metal thickness, and how does it .

Sheet Metal Gauges. The below table summarizes sheet metal gauge and tolerances. Monroe, nor any of its employees shall be held liable for any improper or incorrect use of the information described and/or contained herein and assumes no responsibility for anyone's use of the information. . [in (mm)] Sheet width; 36 (914.4) [in (mm)] 48 (1,219 . Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . referring to a thickness tolerance chart is advisable. Such a chart provides comprehensive insights into the expected variances associated with different materials and . Gauge is a unit of measurement used to indicate the thickness of sheet metal. It's a historical system that's still used in some industries, especially in North America. However, it's important to note that Gauge values can vary depending on the specific standard being used. While Gauge is still used in some applications, it's oftenGauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage. . Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. .

To calculate the sheet metal bend allowance, factors such as plate thickness, bending angle, internal radius, K factor, and others must be taken into account. The sheet metal bend deduction can be obtained once the bend allowance is known. You can either use a formula or a bend allowance chart to calculate the bend allowance. Laser Cutting Metal & Plastic Tolerance Chart. . Sheet Metal: Up to 12 ga (2.5mm) +/- 0.005″ (0.13mm) Sheet Metal: . Dimension Range (mm) Processing Parameters: Test Sample Quantity: Average Value (μm) Standard Deviation (σ) Tolerance (2σ) Metal: Aluminum Alloy 6061: 10-30:The sheet metal does however have a tolerance on the rolling thickness which needs to be taken into account when designing a tight fitting assembly, especially as the sheet metal material gets thicker. . 1000 mm wide sheet metal: 1250 mm wide sheet metal: Group I: Group II: Group I: Group II: 0.61 to 0.80: 0.03: 0.04: 0.06: 0.07: 0.81 to 1.00 .We specialize in providing a wide range of aluminum sheet products that cater to various industries and applications. Click or call 800-333-4140 for a quote. . Tolerance Chart Applications. . there’s no better supplier than Metric Metal. We specialize in providing a range of aluminum sheet products that cater to various industries and .

A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter.Below, you will find the tolerances for plates an sheets, according to alloy group. According to EN 485-4:2000 Alloy Group 1:EN AW-1050A/EN AW-3003/EN AW-5005

“Having a handy guide to compare your called tolerances will profoundly affect your production,” Benson explained. By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, both for .

Tolerance class is defined as per design requirements and manufacturing capability. For example : for sheet metal parts ISO 2768–mk is used. And for machined components ISO 2768–fh can be used. ISO 2768-2 : 1989, General .

This post is to help you understand what the holdable tolerance can be for your sheet metal parts. However even for an experienced designer, it may be difficult and time-consuming to decide the tolerances for each and every dimension, .

removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see . Specifying a tolerance of k 1 mm would be of no benefit in this particular workshop, as the general tolerance values of *0,3 mm would be quiteSheet metal tolerances are the maximum permissible dimension deviation range during sheet metal processing. This concept is vital because it directly affects the quality and performance of the product. Ensuring that every product falls within this tolerance range is essential in our work.

• The latest DIN standard sheet version applies to all parts made to DIN standards. . Ranges in nominal Tolerance class lengths in mm H K L up to 100 0.2 0.4 0.6 over 100 up to 300 0.3 0.6 1 over 300 up to 1000 0.4 0.8 1.5 over 1000 up to 3000 0.5 0.8 2 SYMMETRY .

sheet metal development

Steel Sheet Thickness Tolerances.xls Author: MHumpal Created Date: 6/1/2021 9:00:24 AM .Reference Sheet Metal and Wire Gauge Size Data and Table for various engineering material. . (mm) Galvanized steel in (mm) Stainless steel in (mm) Aluminum in (mm) Zinc in (mm) 3. . Sheet Metal ; Sheet Metal Gauge Tolerances Chart ; Link to this page: Copy Text to clipboard. Bend forming 0°L=A+B-0.43T, T=Thickness, Deduction=0.43T. Formula: L(unfold length)=A(Outside size)+B(Outside size)-K(K-factor) None-90° bend unfold according to the neutral layer, the distance from neutral to sheet inner . Sheet metal Tolerance Standrards, welding Tolerance Standards, General Tolerance Standards, IS 2102 Tolerance details, V groove pulley material . Surface Length (mm) Flatness . Straightness of Cut. 0 to 25. 0.127 mm. 0.41 mm / meter. 25 to 102 . 5 μm / mm of length. above 102. 0.51 mm + 4 μm / mm of length .

typical sheet metal tolerances

Sheet metal material stock has general tolerances for thickness. The following table is a quick reference for standard aluminum 5052 material thickness tolerances. Standard stock material tolerances may vary between alloys and treatments. Sheet metal with tighter tolerances sheet can be specified if required. Stock Material Thickness Tolerances Table of Contents. 1 How Powder Coating Adds Thickness to a Metal Fabricated Part. 1.1 Adjusting tolerances to account for powder coating buildup ; 2 Proactive Designs Pave the Way for Optimal Powder Coating Results; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Powder Coating Tolerance FAQ. 4.0.1 How does powder coating affect the .Sheet Metal Thickness Tolerances - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses tolerances for ArcelorMittal's hot rolled steel products according to European standards. It provides tables with tolerance ranges for thickness and width of steel sheets and plates based on their steel grade category (A, B, C, or D), thickness, and .

tolerance for sheet metal thickness

Wholesale aluminum turned parts with precision CNC machining for industries like automotive, aerospace, and electronics, ensuring high-quality and durability.

sheet metal tolerance chart in mm|sheet metal stamping tolerances