cnc machine tool setting Understanding the concept of tool setting in CNC machines is instrumental in optimizing production processes and ensuring top-quality results. This guide will cover various aspects of . Dedicated to the Collector of Ammunition for Old or Antique Guns or those seeking Obsolete Ammunition. Antique Ammuniton in their Original Boxes, and Obsolete ammunition for use. .

0 · tool setter for cnc mill

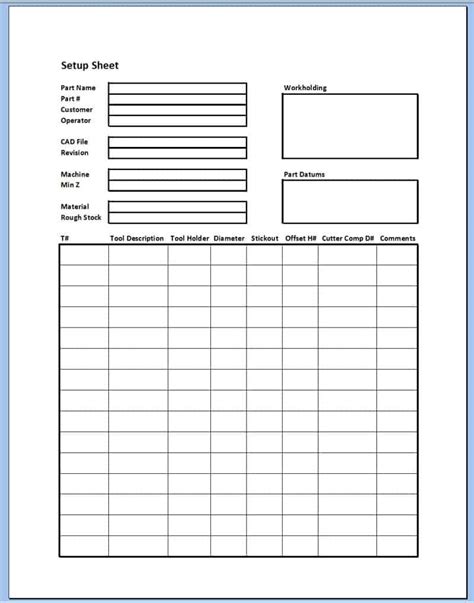

1 · cnc tool set up sheet

2 · cnc setup sheet pdf

3 · cnc mill setup sheet

4 · cnc machining setup sheet

5 · cnc machine setup checklist

6 · cnc lathe setup sheet template

7 · cnc lathe setup sheet

The different types & grades of stainless steel offer different properties, to is why it is used in many applications in many fields. The steel grades and types have useful differences to know to reach the best material .

The basic methods of tool setting in CNC machining include trial cutting method, tool setting instrument and automatic tool setting. Now take a look at below common ways of CNC tool setting. 1. Trial cutting and knife alignmentUnderstanding the concept of tool setting in CNC machines is instrumental in optimizing production processes and ensuring top-quality results. This guide will cover various aspects of .Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting . 【Description】The tool setting instrument is a special tool setting instrument for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control .

Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting .Increase throughput from existing assets; defer capital expenditure, reduce subcontract and overtime bills, and pursue additional business. Increase automation in setting and measurement processes; reduce human intervention and redeploy staff into proactive engineering roles. Give your machine tools the intelligence they need to make decisions for themselves, enabling .

Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting arms.

As a premium laser tool setter for CNC machines, NC4 systems are a beneficial part of any manufacturer's in-process control procedures. . By implementing in-process, automated tool setting, tight tolerances and high-quality finishes can easily be attained. Laser tool setters deliver reliable, non-contact, high-speed measurements with sub . The tool setting instrument is suitable for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control. Note: Package List: 1 x Automatic Tool Setting Gauge .In the field of applications where non-contact tool setters are possible , Mida Laser P is a system capable of measuring tools of any size on machining centers and or milling machines. Utilizing laser technology, Mida Laser P is able to provide extremely precise values of length and diameter even for small tools (less than one millimeter). From the point of view of measurement speed, . These systems are often standalone units that can be used independently of the CNC machine to prepare tools for use. Integrated Tool Setting Systems: Some CNC machines come with integrated tool setting systems as part of a package when purchasing the machine. These systems can be proprietary and specifically designed to work seamlessly with the .

– G-Code snippet that uses G10 to load Tool Info into the machine’s tool table, for example if you’re using offline tool setting. – Digital Photos or CAD drawings of the cutter and toolholder. – Enough other information so that if we break an insert or damage a tool we can use the information to get back up and running ASAP. Overall, CNC milling machines are an essential tool for modern manufacturing and have opened up new possibilities for designers and engineers to create complex and innovative products. Components of a CNC Milling Machine. When setting up a CNC milling machine, it is important to understand the different components that make up the machine. In . Milling Tools CNC Z-Axis Tool Setting Touch Plate Probe Mach3 Router Mill ; Effective Surface Diameter: 30mm. . Package include: 1x CNC Router Engraving Machine Tool Specification Diameter:(Approx.) 40mm Height:(Approx.) 20mm Effective surface of the knife: . The tool setting mode of analog tool angle is adopted, which has the advantages of low cost and convenient operation. It is applied to the calibration of ultrasonic CNC milling straight edge tools in an aircraft manufacturer. In the machining program, just input the corresponding tool number, and the system will automatically complete the reference .

A rough measurement says the tool shank side of the shim is just about on c/l (However this particular tool I'm setting has it's tip 0.45 mm above the top of it's shank so the shim has had to be spaced off that much by the screws - might be the wrong thickness inserts I suppose - I inherited the tool and tips with the machine)

This setting is crucial for different materials and tools. Axis: Refers to the directions in which the CNC machine can move. Most common CNC machines are three-axis (X, Y, and Z), which represent horizontal, vertical, and depth movements. Controller: The computer or device that interprets the G-code and sends commands to the CNC machine.Amazon.com: cnc tool setter. . Aluminum Alloy Z Axis Probe Tool Touch Sensor Setting Gauge for CNC Engraving Machine (Blue) .86 $ 51. 86. FREE delivery Sun, May 12 . Or fastest delivery Wed, May 8 . Only 7 left in stock - order soon. More Buying Choices .02 (3 . This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. . Cutting Tools: CNC lathe machines require various cutting tools to . Most machine tool accessory suppliers will tell you that the majority of shops still set tool-length offsets the old-fashioned way: By touching off each tool one at a time and manually keying in values—hopefully without fat-fingering one along the way. Even on CNC lathes, most of which have a probe arm that allows the operator to simply touch off tools in the X and Z axes, .

Workpiece setting in CNC machining refers to the process of correctly positioning and aligning a workpiece within a CNC machine tool. By accurately setting a workpiece, you reduce the risk of variation and enable precise machining. Automated set up with a probe can also be up to ten times quicker than manual setting, giving the machine tool .the user with the basic set-up and operation of a Haas CNC mill. Machine settings, tool holders, machine offsets and tool presetters and spindle probes will be covered during the . Each brand of CNC machine tool can use a specific retention knob. Refer to the machinesThis page gives detailed descriptions of the settings that control the way that your machine works. List of Settings. Inside the SETTINGS tab, the settings are organized into groups. Use the [UP] and [DOWN] cursor arrow keys to highlight a setting group. Press the [RIGHT] cursor arrow key to see the settings in a group, . Press the [LEFT] cursor arrow key to return to the setting group list. Enter Z0 (Z-axis tool setting completed). At this time, the roughing thread tool setting ends. According to this method, the thread finishing is performed again, and the operation process is exactly the same as the rough turning tool setting method. In this way, random snapping will not occur during the cutting process.

Load G-code into the CNC machine: Transfer the G-code to the CNC machine, ensuring it is correctly formatted and free of errors. Set Tool Offset. Measure tool length: Use a tool setter to measure the tool length accurately. This ensures the correct positioning of the tool relative to the workpiece. Input the tool offset: Enter the measured tool .Process setting Automated on-machine tool setting eliminates manual setting operations. . • Auto-optimisation technology – on-machine measurements are self-optimised for each CNC machine tool. The NC4 allows us to check for breakages of small tools used to make keys and other reference points on the cam, which are

I’m wondering how I can set the tool setter in masso to offset the probe location based on the bit diameter. I have to set on center which works for small EMs. However, for larger bits, such as a 2-1/2" surfacing bit I use, it doesn’t work at all at this location as the cutting inserts are out on the edges outside of the tool probe touch area.

Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting arms.

Buy CNC Z Axis Router Mill Touch Plate Setting Probe Milling Engraving Machine Instrument Tool Zero Sensor Accessories: Milling Machines - Amazon.com FREE DELIVERY possible on eligible purchases . SainSmart CNC Router Z-Axis Tool Setting Touch Probe, Compatible with Grbl/Mach 3 968. .99 $ 9. 99.

diversified metal fabricators smithville mo

tool setter for cnc mill

cnc tool set up sheet

Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications.

cnc machine tool setting|cnc setup sheet pdf