sheet metal hole to edge distance Learn how to design good sheet metal parts with guidelines for hole diameter, bend radius, bend length, and more. The recommended minimum distance between hole edge and bend edge is three times the sheet thickness plus bend radius. Shop the Pigeon and Poodle Redon Modern Antique Brass Ribbed Metal Canister - Small and other Bath Accessories at Kathy Kuo Home

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal extruded hole design

3 · sheet metal drawing standards

4 · sheet metal drawing dimensioning

5 · sheet metal corner relief chart

6 · sheet metal bending guide pdf

7 · minimum flange length sheet metal

Get the best deals on Metal Vintage/Retro Décor Boxes, Jars & Tins when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

Learn how to design good sheet metal parts with guidelines for hole diameter, bend radius, bend length, and more. The recommended minimum distance between hole edge and bend edge is three times the sheet thickness plus bend radius.

K Factor in sheet metal bending is a constant used to calculate sheet metal .

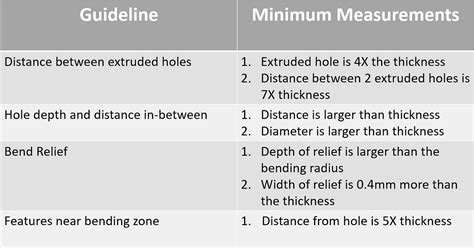

Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced .Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to . Calculating Minimum Edge Distance and Bend Distance. Selecting a hole position too close to a part’s edge or bend radius can significantly impact the performance of the final product. Fortunately, calculating a better hole .

sheet metal rib design guidelines

To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple .

Hardware Placement to Edge: there needs to be a minimum distance from a threaded hole to the edge of a part to make sure the hardware is secure, no damage will occur during threading and that the part will be well . If holes must be near the edge, they should still be at least the distance equal to the sheet thickness (T) from the edge and preferably between 1.5T and 2T from the edge. Distances.

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. .Minimum Distance from Extruded Hole to Part Edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to .

sheet metal fabrication design guide

PEM® REF/ C/L TO EDGE APRIL 2019 SUBJECT: MINIMUM DISTANCE HOLE C/L TO EDGE The term “minimum distance hole-centerline-to-edge” is defined as the minimum distance the mounting hole centerline may be to one edge of a panel to still allow the proper clinching of a fastener into the sheet. When a fastener is close to more than one edge, the .

Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal. t = Sheet metal thickness If holes must be near the edge, they should still be at least the distance equal to the sheet thickness (T) from the edge and preferably between 1.5T and 2T from the edge.Prior to squeezing the trigger on an air drill, the chuck should be turned by hand at the point of drilling the material to make a slight indentation.Also same for edge of part and bend lines in sheet metal. Reply reply . In short, 4 x hole diameter for center to center spacing and 2 x hole diameter for edge distance from the center of the hole. Good rule of thumb for most structural applications. Reply reply

sheet metal extruded hole design

Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Hole Diameters. Hole Spacing. Bend .Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Related concepts. Hole Diameters .

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design. . there needs to be a minimum distance from a threaded .Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously automotive - sheet metal part design plays a role in most modern products.

Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Hole Diameters. Hole Spacing. Bend .

2.2 The minimum distance between a counterbore to an edge should be four times the thickness of the metal sheet. 2.3 The minimum distance between a counterbore to a bend should four times the thickness of the metal sheet + bend radius. 3. Countersinks: These are conical-shaped holes created in a metal sheet to hold a countersunk bolt or screw . Information on the necessary edge distances in wooden components can be found, for example, in DIN EN 1995-1-1: 2010-12 (Eurocode 5). There are various parameters to consider, which have an influence on the required edge distance: Direction of the grain of the wood; Angle between force and grain direction; Loaded / unloaded edgeWha are the rules for minimum and maximum edge distance? . 3xs diameter. The two hole duplication methods are called? Back drilling and marking. The preferred marking medium for aluminum alloy is the common no.2 pencil. . FALSE. What is the distance from the center of the rivet to the nearest edge of a sheet called by the Boeing a/c company .Hole-to-edge distance Slot-to-bend distance Slot-to-edge distance SHEET METAL GUIDE V2.2 — TOLERANCES. Notches & Tabs DIMENSIONS The minimum thickness a notch must maintain is at least 0.04” (1mm) or the material’s thickness, whichever is greater; the length must be no larger than 5 times its

We’d need to calculate 0.209”/2 + 0.063” to find the minimum distance from the center of the tapped holes to the nearest cut feature.. The minimum distance for a 1/4-20 tap in 0.125” 5052 aluminum is 0.167”.. Then, . Tapped hole diameter/2 + the minimum tap hole-to-edge distance for the chosen material. The minimum hole-to-edge distance for each material can be found on our Materials Page under the “Design Considerations” heading. .Prepare properly sized mounting hole in sheet. Do not perform any secondary operations such as deburring. Step 2. Place shank of self clinching nut into mounting hole, preferably the punch side. Step 3. With punch and anvil .Lay out and prick punch all the holes, insert the proper size of punch or die into the hand lever punch, place the sheet metal pattern on the workbench with the holes to be punched extending 1" to 2" beyond the edge of the workbench use bench weights, place the centering point of the metal of the male punch in the center of the marked hole .

sheet metal drawing standards

Study with Quizlet and memorize flashcards containing terms like Drill diameters are grouped by three size standards, When drilling a hole for rivet installation the proper hole will have a clearance of___greater than the largest tolerance of the rivet shank diameter., T or F The edge distance required when using flush fasteners is the same as when protruding -head fasteners .what drill bit is used to cut holes for 1/8 diameter rivet . What should not be used when doing a layout on sheet metal aluminum? A scribe. What is used as an aid when doing layout work with pencil? . The Structural Repair Manual. What are the limits for edge distance with a MS20426AD4-5 rivet?.25" min and .5" max. What are the safety .

Curls are hollow circular rolls formed at the edge of the sheet via sheet metal bending. Curl features are commonly used to provide strength to a part and to remove sharp edges from the workpiece so that it is safe to handle. . To ensure successful bending, it is recommended to place holes away from bends at a distance of at least 2.5 times .

Or just design it so the holes are the appropriate distance from the bend radius . Unfortunately many engineers aren't sheet metal experts. In CAD you can draw pretty much anything. In the real world there are constraints. . I observe there will still have distortion on holes edge but compare to normal V-die the deformed edge is press into .45° gussets shouldn’t be designed to be more than 4 times material thickness on their flat edge; For holes, the distance between the gusset and the hole’s edge should be at least 8 times material thickness. Hems. Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.Perforated metal is nothing but a pattern of holes on a sheet metal surface. It has endless applications in enclosures, partitions, sign panels, guards and screens as it offer several benefits . It is recommended that the minimum distance from the edge of a circular hole to a bend should be 3 times the material thickness

Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Hole Diameters. Hole Spacing. Bend .Small holes in sheet metal can be punched or can be laser cut, depending on the equipment used for punching. As general guideline suggests , hole diameter equal to sheet thickness can be punched. If the hole diameter is too small, then chances of punch breaking or bending during operation is high. . L= Bend Edge to Relief Edge Distance. Hole .

sheet metal drawing dimensioning

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

sheet metal corner relief chart

Get the best deals for Vintage Chicken Nesting Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

sheet metal hole to edge distance|sheet metal fabrication design guide