cnc chuck parts Collet chucks are best suited for parts ranging in size from 1/16″ to 4″ in diameter because they offer much better tool clearance, can be run at higher speeds than jaw chucks, and provide superior grip force. A forum community dedicated to Jeep Wrangler owners and enthusiasts. Come join the discussion about reviews, performance, trail riding, gear, suspension, tires, classifieds, .

0 · what is solid chuck

1 · what is a chuck engineering

2 · types of collet chucks

3 · strong lathe chucks

4 · replacement chucks for cnc machines

5 · power chucks for cnc lathes

6 · kitagawa chuck catalogue

7 · chuck jaws for kitagawa

From architectural applications to machine guarding, we have woven wire mesh for your application. Examples of common applications include: Woven wire mesh baskets; Woven wire mesh architectural grilles; Woven wire mesh display shelves and stands; Woven wire mesh racks; Woven wire mesh liquid filtration; Woven wire mesh air filtration; Woven .

Kitagawa is the global, premier brand of workholding and power chucks for over 65 years. Today, we manufacture and supply a comprehensive array of standard power chucks, advanced .

Today, we manufacture and supply a comprehensive array of standard power .A standard CNC chuck typically consists of the following parts: 1. Body: The main body of the chuck that houses the jaws or collets. 2. Jaws or Collets: The parts that grip the workpiece. 3. Actuator: The mechanism that opens and closes .Collet chucks are best suited for parts ranging in size from 1/16″ to 4″ in diameter because they offer much better tool clearance, can be run at higher speeds than jaw chucks, and provide superior grip force.Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all .

The Most Advanced Collet Chucks Available for Today’s CNC Lathes Ten-Second Collet Changes Slash Setup Times. Industry-Leading Gripping Range – 0.062″/0.080″.To order replacement parts for your Haas CNC machine, please use our distributor locator tool below to find your local Haas Factory Outlet. Your local HFO will be able to find and deliver .

We have chuck accessories and replacement parts available for you. The accessories and replacement parts are also interchangeable with other chuck brands. Email: [email protected] | Phone: (888) 988-8820 Understanding the specific uses of the different CNC chuck types, from the uniform grip of a three-jaw to the adjustable pressure of a collet, is vital for machinists to optimize their CNC operations for quality and performance.

Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.

Kitagawa is the global, premier brand of workholding and power chucks for over 65 years. Today, we manufacture and supply a comprehensive array of standard power chucks, advanced chucks, manual chucks, oil & gas chucks, collet chucks, engineered and custom solutions, grease and accessories, steady rests, rotary hyrdraulic cylinders, NC rotary tables, vises, work grippers, .A standard CNC chuck typically consists of the following parts: 1. Body: The main body of the chuck that houses the jaws or collets. 2. Jaws or Collets: The parts that grip the workpiece. 3. Actuator: The mechanism that opens and closes the jaws or collets. 4. Base Plate: The bottom part of the chuck that attaches to the CNC machine spindle. 5.Collet chucks are best suited for parts ranging in size from 1/16″ to 4″ in diameter because they offer much better tool clearance, can be run at higher speeds than jaw chucks, and provide superior grip force.

Today, we manufacture and supply a comprehensive array of standard power chucks, advanced chucks, manual chucks, oil & gas chucks, collet chucks, engineered and custom solutions, grease and accessories, steady rests, rotary hyrdraulic cylinders, NC rotary tables, vises, work grippers, robot grippers, automation products, angle heads, shrinkfit .Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.The Most Advanced Collet Chucks Available for Today’s CNC Lathes Ten-Second Collet Changes Slash Setup Times. Industry-Leading Gripping Range – 0.062″/0.080″.To order replacement parts for your Haas CNC machine, please use our distributor locator tool below to find your local Haas Factory Outlet. Your local HFO will be able to find and deliver your factory replacement parts, based on the specific model and year of .

We have chuck accessories and replacement parts available for you. The accessories and replacement parts are also interchangeable with other chuck brands. Email: [email protected] | Phone: (888) 988-8820 Understanding the specific uses of the different CNC chuck types, from the uniform grip of a three-jaw to the adjustable pressure of a collet, is vital for machinists to optimize their CNC operations for quality and performance.Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.Kitagawa is the global, premier brand of workholding and power chucks for over 65 years. Today, we manufacture and supply a comprehensive array of standard power chucks, advanced chucks, manual chucks, oil & gas chucks, collet chucks, engineered and custom solutions, grease and accessories, steady rests, rotary hyrdraulic cylinders, NC rotary tables, vises, work grippers, .

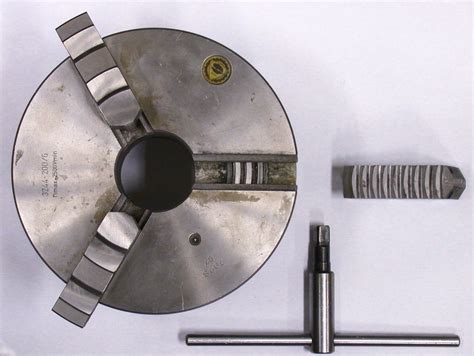

A standard CNC chuck typically consists of the following parts: 1. Body: The main body of the chuck that houses the jaws or collets. 2. Jaws or Collets: The parts that grip the workpiece. 3. Actuator: The mechanism that opens and closes the jaws or collets. 4. Base Plate: The bottom part of the chuck that attaches to the CNC machine spindle. 5.Collet chucks are best suited for parts ranging in size from 1/16″ to 4″ in diameter because they offer much better tool clearance, can be run at higher speeds than jaw chucks, and provide superior grip force.

Today, we manufacture and supply a comprehensive array of standard power chucks, advanced chucks, manual chucks, oil & gas chucks, collet chucks, engineered and custom solutions, grease and accessories, steady rests, rotary hyrdraulic cylinders, NC rotary tables, vises, work grippers, robot grippers, automation products, angle heads, shrinkfit .Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.The Most Advanced Collet Chucks Available for Today’s CNC Lathes Ten-Second Collet Changes Slash Setup Times. Industry-Leading Gripping Range – 0.062″/0.080″.To order replacement parts for your Haas CNC machine, please use our distributor locator tool below to find your local Haas Factory Outlet. Your local HFO will be able to find and deliver your factory replacement parts, based on the specific model and year of .

We have chuck accessories and replacement parts available for you. The accessories and replacement parts are also interchangeable with other chuck brands. Email: [email protected] | Phone: (888) 988-8820

what is solid chuck

Understanding the specific uses of the different CNC chuck types, from the uniform grip of a three-jaw to the adjustable pressure of a collet, is vital for machinists to optimize their CNC operations for quality and performance.

how to box out steel beam

Advantages of the precision sheet metal jobs were indoors, you have your own bench and tools, no need to travel to job sites or climb up ladders etc. Plus its very hard to learn, and keeps out .

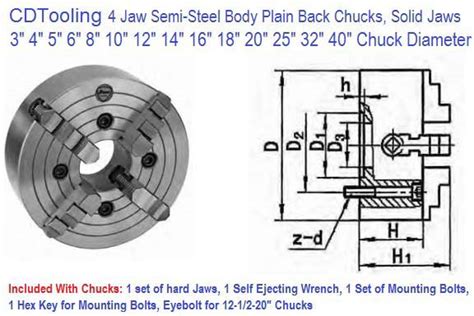

cnc chuck parts|what is a chuck engineering