which do cnc machines use to control tool motion We explain the motion control system used in CNC machine tools by simplifying the process and comparing it to driving a car. What qualities make a good sheet metal worker? A good sheet metal worker is detail-oriented, ensuring precise measurements and cuts. They need to be physically fit, as the job often .

0 · which of the following controlled the movements of nc machines

1 · which control system allows cutting during tool movement

2 · which components move during cnc machining

3 · what type of movement uses multiple axes of motion at once

4 · what device executed part programs on an nc machine

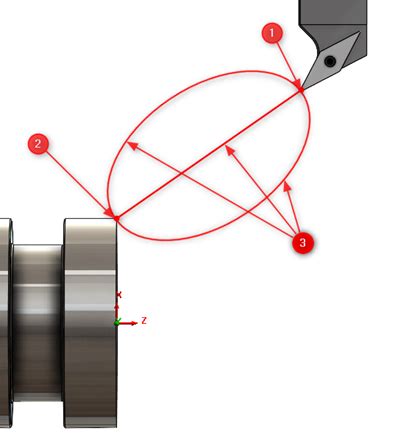

5 · polar interpolation in c axis

6 · interpolation in cnc

7 · fanuc cnc controller list

Download our guide for sheet metal manufacturability recommendations to optimise your designs and lower your costs

Motion control is a relatively simple function in any CNC machine. It is an accurate, consistent and automatic control system. CNC machines require two or more directional modes, which are called axes. There are two common . The command almost all CNC machines use to initiate rapid motion is G00. Within the G00 command, the end point for the motion is given. Control manufacturers vary with .

The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and . The CNC control is responsible for processing, programming and coordinating the movements of a machine. Meanwhile, the drive technology in the form of stepper motors, servo or direct drives enables the physical movement .We explain the motion control system used in CNC machine tools by simplifying the process and comparing it to driving a car.The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC machines have two or more directions of motion, called axes. These axes .

The fundamental function of any CNC machine is to achieve automatic, precise, and consistent motion control. CNC machines possess two or more axes for various directions of motion. These axes are automatically and accurately .

The most rudimentary function of any core of CNC machine is automatic, accurate, and steady motion control. Rather than applying totally mechanical devices, as is obligatory on most conventional machine tools, .

CNC machines, equipped with sophisticated control systems, play a vital role in guiding tool motion. In this blog post, we will delve into the mechanisms and components that CNC . The most rudimentary function of any core of CNC machine is automatic, accurate, and steady motion control. Rather than applying totally mechanical devices, as is obligatory on most conventional machine tools, .QUESTION: Which do CNC machines use to control tool motion? POSSIBLE ANSWERS: Manual controls, including buttons, cranks, and levers. Programs punched into paper or mylar tape. Words written in numerical data.

The CNC machine uses programmable commands to make it easier to input motion to the CNC machine, rather than using a crank or other conventional machine tools. Almost all CNC machines can have . Which do CNC machines use to control tool motion? CNC machines rely on a system of three linear and three rotational axes in order to calculate the motion and position of machine components and workpieces. A machine control unit controls and guides the movements of the machine tool. Additionally, closed-loop systems provide feedback, while open .

CNC machines primarily use G-code as their programming language, which stands for “Geometric Code.” This standardized language consists of alphanumeric commands that control various aspects of the machine’s operation, .

CNC machine uses the program to control motion and speed. 6. Machine control unit implements interpolation commands to generate axial motion commands. a) True b) False. Answer: a Clarification: Machine control unit implements interpolation commands to generate axial motion commands. It reads the code provided and decodes the instruction. 7.Study with Quizlet and memorize flashcards containing terms like What part of a CNC system reads and executes the machining instructions in the part program?, What is the purpose of a CNC machining center? Machining centers enable a single machine to:, Which of the following is an advantage of CNC systems? CNC systems: and more.

GENERAL MOTION VS. CNC IN MACHINE TOOL APPLICATIONS. Traditionally, CNC has been the control of choice for machine tool applications. However, general motion control (GMC) can be used in many machine tool applications to simplify the overall machine and reduce costs. The increase of GMC in the machine tool industry is due in large part to the availability of new . Inkscape is a free and open-source CNC software commonly used in laser cutting for its great 2D design tools. And for all the same reasons, it’s great for 2D CNC cutting as vectors work perfectly for projects with text and image designs. For more complex and advanced design projects, using Inkscape (free) or Adobe Illustrator (.99/month) can be easier for the initial .

This motion control board supports 4-axis linkage, meaning you can use it to control both 3-axis and 4-axis CNC machines, so it’s suitable for virtually any hobbyist project. Both the software and controller are also compatible with almost any type of CNC machine. The maximum step pulse frequency is 100KHz, which is optimal for engraving.CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components:

which of the following controlled the movements of nc machines

There are three major motion types that all CNC machines use. These motion patterns include swift, angular, and circular movements. . To control the tool’s motions, is commonly done in either inches per minute or millimeters per minute. For turning and milling, however, it may also be set in a per-revolution format, which is very helpful. .A machine tool is a device capable of shaping or machining metal or other rigid materials through an automated process known as Computer Numerical Control (CNC). Milling, cutting, drilling, as well as other CNC machines, are preprogrammed to account for pattern designs, material types, tools used, speed of operation, etc. Motion control is an important aspect of industrial robots and plasma CNC machines. In the old days, CNC positioning was controlled by a hand crank, requiring physical interaction by the engineer. Now, operators rely on motion control to streamline the moving process. Read on to learn more about CNC motion control, its uses, and the types .Study with Quizlet and memorize flashcards containing terms like When we use the term "crash" on a machine tool, we are primarily speaking of:, Crashing a CNC machine results in downtime for the machine, and can be very costly to .

CNCMotion takes simulation to the next level. Beyond displaying the tool path on the part, CNCMotion simulates all aspects of machine operation on-screen in 3-D; a virtual machine! Programming and control. Fully integrated with CNCBase . The ease of setting up and operating CNC machines contributes to swift project completion, a significant advantage in time-sensitive situations. Motion Control. A defining feature of CNC machines is their ability to move in multiple directions or axes. These axes, which can be linear or rotary, are positioned with high precision and can be .Study with Quizlet and memorize flashcards containing terms like All CNC machines contain three different components, select these components., What are the three main ways G & M code can be created for a CNC machine?, CNC milling G & M code is based off the _________ Coordinate System. and more.Study with Quizlet and memorize flashcards containing terms like Which of the following controlled the movements of NC machines?, Which of the following is a benefit of CNC machines?, Which CNC machine uses force to create bends or holes in sheet metal? and more.

Introduction Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by automating various processes. From cutting and drilling to milling and shaping, CNC machines offer precision and efficiency. In this article, we will delve into the details of what a CNC machine is, how it works, its applications, and the benefits it offers. . A: Both M and G codes are used together when programming CNC machines because they offer complete control over them. It should be noted that while m codes deals with switching spindles on/off activating coolants controlling tool changers among others g commands handle motion/positioning of machine tools . The control of a CNC lathe or CNC milling machine thus takes over many tasks that are mainly performed by the machine operator on conventional machine tools. These include controlling the production steps, monitoring production sequences, saving machine and tool data, saving and executing production programs and graphically simulating .

china cnc machine tool fair 2018

Tooling for CNC Machines. CNC machines use various cutting tools such as end mills, drills, reamers, taps, and turning tools. Tool selection depends on the material, operation, and desired geometry. Important considerations include tool material (carbide, HSS, ceramics), coatings, flute count, and tool holding. What language do CNC machines use? The industry has standardized on G-Code as its basic set of CNC machine codes. G-Code is the most popular programming language used for programming CNC machinery. What is the difference between CNC and VMC? CNC is a type of motion control system.Overall, CNC controllers and motion controllers play a crucial role in the manufacturing industry, enabling advanced and precise control over machine movements and operations. Typical applications include: Milling and Turning Machines; Plasma Laser and Water Cutting Machines; Routing Machines; Stone Engraving and Cutting Machines

Okuma America Corporation, a manufacturer of computer numeric control (CNC) machine tools, has announced the launch of its next-generation machine control for its line of CNC machine tools. The new control — the Okuma OSP-P500 — is the company's latest innovation within its OSP control line.A calibration process of DMG Mori CNC machine Key Takeaways are: Understanding CNC Machine Structure: The structure of a CNC machine is complex, with several key components including the control software, drive system, linear guides and ball screws, spindle, tool length sensor, and coolant system. Each of these components plays a crucial role in the machine’s .

china cnc machining extruded aluminum parts

Our metal fabric designs come from the most advanced technical weaving mill in .

which do cnc machines use to control tool motion|which of the following controlled the movements of nc machines