advantages and disadvantage of sheet metal process pdf The drawbacks for the sheet metal forming process are the production rate and part accuracy, while high formability and flexibility are consider as main advantage in ISMF. The aim of this . Get information, directions, products, services, phone numbers, and reviews on Wayne Sheet Metal Works in Jesup, undefined Discover more Fabricated Plate Work (Boiler Shops) companies in Jesup on Manta.com

0 · spinning sheet metal process

1 · sheet metal shearing process PDF

2 · sheet metal cutting strength

3 · sheet metal cutting process

4 · sheet metal cutting force

Watkins Metal Fabrication in Mineral Wells, reviews by real people. Yelp is a fun and easy way to find, recommend and talk about what’s great and not so great .

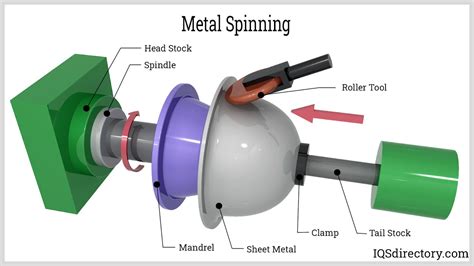

spinning sheet metal process

Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell. The sheet metal parts that have circular cross-section can be made by this process.The drawbacks for the sheet metal forming process are the production rate and part accuracy, while high formability and flexibility are consider as main advantage in ISMF. The aim of this .

Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production. Several innovations .

large steel freestanding floor parcel lockable drop slot mail box

Sheet metal parts have the advantage of high elastic modulus and yield strength, allowing the parts produced to be stiff and have an excellent strength-to-weight ratio. This book navigates .Abstract- Conventional, Single, Two and Multipoint Incremental Forming (CIF, SPIF, TPIF and MPIF) Processes is an innovative forming approach for sheet materials.While also the difference between shearing, slitting, punching, notching, and blanking processes, and the advantages and disadvantages of the shearing process/ operation. how the shearing operation has bettered the .There are five types of processes that are generally used in press-work sheet-metal forming: (a) open shearing, (b) blanking, (c) piercing, (d) bending, and (e) deep drawing. Prior to .

Advantages: (1) enhanced plastic deformation properties, (2) lower forces required, (3) intricate work geometries possible, (4) annealing stages can be reduced. Hot working: Involves . It explains what shearing operations are and how the shearing process is operated in metal forming. While also outlining the difference between shearing, slitting, punching, notching, and.

While also outlining the difference between shearing, slitting, punching, notching, and blanking processes, and the advantages and disadvantages of the shearing process are detailed. .Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell. The sheet metal parts that have circular cross-section can be made by this process.

The drawbacks for the sheet metal forming process are the production rate and part accuracy, while high formability and flexibility are consider as main advantage in ISMF. The aim of this paper is to understand the ISMF process, their key features, and parameter influencing the process, advantage, disadvantage and application.Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production. Several innovations have improved working conditions in shearing process applications.Sheet metal parts have the advantage of high elastic modulus and yield strength, allowing the parts produced to be stiff and have an excellent strength-to-weight ratio. This book navigates the complex interplay of material behaviour, tooling design, and process refnement from fundamental principles to advanced simu-lations.Abstract- Conventional, Single, Two and Multipoint Incremental Forming (CIF, SPIF, TPIF and MPIF) Processes is an innovative forming approach for sheet materials.

While also the difference between shearing, slitting, punching, notching, and blanking processes, and the advantages and disadvantages of the shearing process/ operation. how the shearing operation has bettered the manufacturing product. Three cases were given on the recent advancement in the use of shearing operation.There are five types of processes that are generally used in press-work sheet-metal forming: (a) open shearing, (b) blanking, (c) piercing, (d) bending, and (e) deep drawing. Prior to discussing these processes, it is useful to make a distinction between a metal-plate and a metal-sheet.

Advantages: (1) enhanced plastic deformation properties, (2) lower forces required, (3) intricate work geometries possible, (4) annealing stages can be reduced. Hot working: Involves deformation above recrystallization temperature, between 0.5Tm to 0.75Tm.

It explains what shearing operations are and how the shearing process is operated in metal forming. While also outlining the difference between shearing, slitting, punching, notching, and.

While also outlining the difference between shearing, slitting, punching, notching, and blanking processes, and the advantages and disadvantages of the shearing process are detailed. Different types of modern shearing machines are documented.Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell. The sheet metal parts that have circular cross-section can be made by this process.The drawbacks for the sheet metal forming process are the production rate and part accuracy, while high formability and flexibility are consider as main advantage in ISMF. The aim of this paper is to understand the ISMF process, their key features, and parameter influencing the process, advantage, disadvantage and application.Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production. Several innovations have improved working conditions in shearing process applications.

Sheet metal parts have the advantage of high elastic modulus and yield strength, allowing the parts produced to be stiff and have an excellent strength-to-weight ratio. This book navigates the complex interplay of material behaviour, tooling design, and process refnement from fundamental principles to advanced simu-lations.Abstract- Conventional, Single, Two and Multipoint Incremental Forming (CIF, SPIF, TPIF and MPIF) Processes is an innovative forming approach for sheet materials.While also the difference between shearing, slitting, punching, notching, and blanking processes, and the advantages and disadvantages of the shearing process/ operation. how the shearing operation has bettered the manufacturing product. Three cases were given on the recent advancement in the use of shearing operation.

There are five types of processes that are generally used in press-work sheet-metal forming: (a) open shearing, (b) blanking, (c) piercing, (d) bending, and (e) deep drawing. Prior to discussing these processes, it is useful to make a distinction between a metal-plate and a metal-sheet.Advantages: (1) enhanced plastic deformation properties, (2) lower forces required, (3) intricate work geometries possible, (4) annealing stages can be reduced. Hot working: Involves deformation above recrystallization temperature, between 0.5Tm to 0.75Tm.

It explains what shearing operations are and how the shearing process is operated in metal forming. While also outlining the difference between shearing, slitting, punching, notching, and.

largest metal fabricators

Find the perfect Waterproof Junction Box to enhance your next adventure, plenty of options in our comprehensive selection!

advantages and disadvantage of sheet metal process pdf|sheet metal cutting process