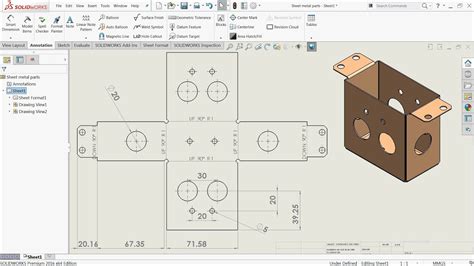

sheet metal parts drawings In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. 1. Manufacturing process mapping 2. Flat . See more Our built-in meter boxes are designed to mirror standard recessed meter boxes. Our gas cover boxes are designed to house all domestic U6 and G4 meters and are fully approved to National Grid specifications. If you're looking for surface meter boxes, we .

0 · solidworks sheet metal drawings

1 · simple sheet metal drawings

2 · sheet metal layout drawings

3 · sheet metal drawings with gd&t

4 · sheet metal command in solidworks

5 · sheet metal basic drawing

6 · sheet metal 3d sketch solidworks

7 · metal sheet riveted together drawing

Comparing die casting vs. others, such as sand casting or forging, reveals its superior precision and smoother surface finishes. Plus, die casting allows for thinner walls and can integrate fastening elements directly into the mold design, reducing assembly operations and increasing structural integrity.

Learn design for manufacturability (DFM) considerations, flat pattern views, dimensioning, and GD&T for sheet metal parts. This guide covers the basics of engineering drawings and provides tips for sheet metal specific details. See more

In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. 1. Manufacturing process mapping 2. Flat . See moreJust like any other part drawing, there are some standard items you will need to include on your sheet metal drawings in order to generate easy to interpret 2D drawings that . See moreBecause sheet metal components require multiple manufacturing processes, proper file preparation can speed up both the quoting and production processes. The first step is to speak with your manufacturers and learn what file formats they prefer for each process. This can reduce file conversion workload, which is often a source of . See more

For the sake of completeness and clarity, we’ve included downloadable example files below that represent a typical set of complete manufacturing output files. PDF B - size drawing DXF file with boarders, dimensions, and all annotations removed STEP file of 3d geometry See more Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the . Learn how to optimize your sheet metal drawings for faster and more accurate fabrication. Find out the best practices for part numbers, hardware, revision control, grain direction, and powder coat instructions.

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, .The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this .

Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent . What is Sheet Metal Drawing? Sheet Metal drawing process. Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without . How to Create Sheet Metal Drawings - Flat Patterns, Cut Lists, Multi-Body Views. In this SOLIDWORKS tutorial, Roland demonstrates how to create detailed drawings and DXFs of different configurations using multi body .to transfer the sheet metal information. Form the help: “Transfers the sheet metal and flat pattern information from the original part to the mirrored part such as fixed face, grain direction, bend lines, and bounding box. Some sheet metal .

Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.

Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.

solidworks sheet metal drawings

The Basics of Sheet Metal Shop Drawings. Sheet metal shop drawings are detailed technical drawings that provide instructions and information for the fabrication and assembly of sheet metal components. These drawings are typically created by engineers or draftspersons and used by sheet metal fabricators to produce accurate and precise products. How to Create Sheet Metal Drawings - Flat Patterns, Cut Lists, Multi-Body Views In this SOLIDWORKS tutorial, Roland demonstrates how to create detailed drawings and DXFs of different configurations using multi body parts in Solidworks. He covers flattening bodies, creating drawings from any configuration, generating manufacturing information .

Measuring Tolerance Representation Accuracy is critical in sheet metal fabrication drawings, to ensure that fabricated parts meet design specifications and fit together correctly during assembly. Sheet metal tolerances refer to the maximum permissible deviation range in the dimensions during sheet metal processing.

1 Pro/SHEETMETAL Figure SM.1 Bracket and Bracket Detail Drawing OBJECTIVES • Model sheet metal parts and create sheet metal drawings • Create walls, reliefs, and bends • Understand and create Bend Order Tables • Produce Flat Pattern Instances of sheet metal parts • Create form features and rips • Produce Sheetmetal drawings Pro/SHEETMETALDrawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematic

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes. For example, if you are designing simple folded sheet metal parts, you are only needing to design some flanges with rounded radii: a simple sheet metal module. . you could draft in an old-school way and do it all in 2D. Many legacy manufacturers still work in 2D DWG and DXF drawings. So, there is a high chance you'll be fine with just .

Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.cutting beam gets scattered. Material that is too thick has the same problem: molten metal scatters the beam before the part is fully cut. We can cut metal as thick as 3/8" but the edge quality suffers greatly. The degree of material flammability is another important factor. Some parts considered flammable can be used.I typically use one drawing per individual sheet metal part, and if it is welded that is treated as one weldment part. . The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating . Drawings will need to be converted to a flat pattern for fabrication, however, and 2D drawings are far more useable in sheet metal manufacturing. Where 3D drawings are used, they should be made with a sheet metal module, and good design practices should be followed so that the 3D dimensions match the 2D design.

sheet metal fabrication| sheet metal processing| cnc machining| precision machining| sheet metal stamping| steel sheet metal fabrication . Poor drawings lead to poor quality parts. Parts of "bad quality" always have defects; the more serious the defect, the poorer the quality. Poor quality with poor reliability means no after-sales service is .

simple sheet metal drawings

electrical outlet from light box

Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard toolbar), and click OK to open the drawing sheet.. Select a format or click OK to use the default format.. From the View Palette, drag the Flat pattern to the drawing sheet. You can adjust the size of the drawing view under Scale by selecting Use custom scale, .

Tips for sheet metal design dimensioning . While there are several thumb rules and guidelines for dimensioning the drawings for sheet metal fabrication, we have enlisted a few important and frequently used aspects. Drawings should not have broken geometry when depicting sheet metal parts; Show grain direction in parts made of stainless steel Processing sheet metal materials from ultra-high-strength steels represents a promising and economically viable approach to produce sophisticated, light-weight car body structures [].Yet deep drawing of such dedicated high-strength steels poses a challenging task for manufacturers due to their limited formability, the high process loads during forming and the . JIATONG XJ was found in March 2011, situated in humen town, with a plant area of 8200 square meters, one of China’s professional precison sheet metal manufacturer over 10 years.Offerring you One-stop integrated ODM& OEM manufacturing solutions and services including sheet metal machining, welding, painting, silkscreen, assembly.etc, from primary .Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard toolbar), and click OK to open the drawing sheet. Select a format or click OK to use the default format. From the View Palette, drag the Flat pattern to the drawing sheet.

Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. Toggling the Visibility of Sheet Metal Bend Notes. In my experience with sheetmetal, a bend in sheet metal is a 'bend', so your flat pattern drawing will show th 'bend lines'. The only time I ever saw or used the word 'break' on a sheet metal drawing was in calling out the occasional 'tension break' aka 'cross break' to prevent a flat panel from oilcanning. YMMV

electrical outlet boxes for drywall pictures

sheet metal layout drawings

The incoming Republican majority in the House of Representatives removed metal detectors outside of the chamber floor on Tuesday, just three days before the second anniversary of the deadly Jan. 6 riot.

sheet metal parts drawings|sheet metal basic drawing