sheet metal pattern development Radial Line Pattern Development. 20. Right Cone. 21. Pyramid. 22. Frustum of a . The primary concern with galvanized steel is whether or not it will oxidize, leading to potential rusting. Galvanized steel is an ideal option for outdoor use due to its remarkable capability of withstanding corrosion. However, some people still wonder if .

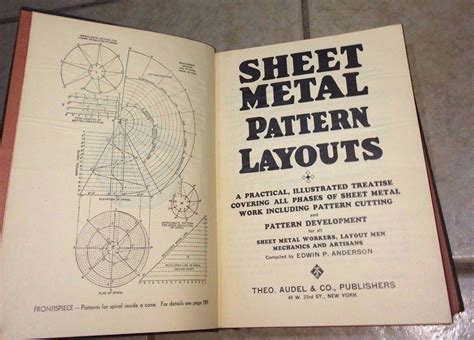

0 · sheet metal pattern layouts pdf

1 · sheet metal pattern layout methods

2 · sheet metal layout software free

3 · sheet metal layout pdf

4 · sheet metal fittings layout drawing

5 · sheet metal development drawing pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

Lowe’s does provide services to cut many materials including metal rods, chains, wood pieces, and metal pipe if you have requested them. However, they lack the necessary equipment to cut metal sheets.

Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It .Triangles (A-B-C), squares or rectangles (A-B-C-D), and circles are some of the .

Radial Line Pattern Development. 20. Right Cone. 21. Pyramid. 22. Frustum of a .

Pattern Development: Sheet Metal Level 1 by Brian Coey was funded by .The process of pattern development gives us the ability to take that visual .Radial Line Pattern Development. 20. Right Cone. 21. Pyramid. 22. Frustum of a .

The process of pattern development is the way we turn 2D sheets of metal into 3D .

Pattern Development: Sheet Metal Level 1. Versioning History This page provides a .

Pattern Development: Sheet Metal Level 1. Geometric Construction Introduction. As .Radial Line Pattern Development In Parallel Line Pattern Development, we required .

Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both .The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional .The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an .From creating 2D patterns of 3D objects, to making sure roof panels are installed square, to locating duct runs and penetrations, geometry is used everyday by a sheet metal worker. This .

sheet metal pattern layouts pdf

Advanced Pattern Development. By this time in your training, we are looking at advanced pattern development of various fittings. This will begin to introduce us to a combination of methods .

sheet metal pattern layout methods

Unfolding software for commonly used shapes used in Metals, Plastics and Insulation Industries. Stand-alone program, does not require additional software. Print or Plot the pattern layout. .A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. Sheet metal layout drawings are based on three .Triangles (A-B-C), squares or rectangles (A-B-C-D), and circles are some of the most common shapes seen in the sheet metal industry. It is a combination of points, lines, and angles that .In Level 2 we will expand on previously learned processes in parallel line and radial line as well as a new technique in triangulation, developing pattern from elevation view instead of plan view.

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. . When the development is finished, the machinist .

limited purpose of pattern development, this book meets every requirement of an apprenticeship textbook and is, in addition, also well adapted for . The paper generally used for sheet-metal pattern drafting is known as brown detail paper. However, for finished drawings, white craft paper is more suitable. It can be bought of almost any width,Getting the flattened pattern of sheet metal fabrication parts by hand is time consuming, requires lots of knowledge, and it is prone to errors and not reliable.. There are lots of good sheet metal pattern development software programs .

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt.

Image 5 of The universal sheet metal pattern cutter; a comprehensive treatise on all branches of . The Universal Sheet Metal Pattern Cutter A COMPREHENSIVE TREATISE ON ALL BRANCHES OF SHEET METAL PATTERN DEVELOPMENT Volume II ARCHITECTURAL SHEET METAL WORK Including Drawing, (Full Size) Detailing and Lettering, Development and.In Parallel Line Pattern Development, we required parallel element line or bends. Some objects are of a conical shape and parallel line will not work on them. Rather, we will look at using Radial Line Pattern Development. In radial line, we develop patterns for shapes that have a taper, all element lines (bends) must radiate back to a common .Sheet Lightning is unfolding software for designing and unwrapping pattern developments for sheet metal designs. It combines an integrated parametric library and a full 3D CAD design environment. The parametric design facility means designs can be created by simply loading a template design and typing in new dimension values.

Pattern Development: Sheet Metal Level 3. 7 Round Y-Branch Make sure the fitting is sized correctly. Remember some of the sizing rules for y-branches: the crotch height must be ¾ of the base diameter (or 1.5x the radius), the small openings must equal the large- A2 + B2 = C2 can be used to size the fitting correctly .Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an object are indeed parallel. The two ends of the part must be the same.

cnc sheet metal bending machine

Sheet metal drawing and pattern development by Dickason, A. (Alfred) Publication date 1983 Topics Mechanical drawing, Technical drawings Draftsmanship - For technicians Publisher London : Pitman Collection internetarchivebooks; inlibrary; printdisabled Contributor Internet Archive Language English

cnc router parts spindle

The universal sheet metal pattern cutter; a comprehensive treatise on all branches of sheet metal pattern development by Neubecker, William, 1864- [from old catalog] Publication date 1920 Topics Sheet-metal work Publisher New York, N.Y., The Sheet metal publication company Collection library_of_congress; americanaA sheet metal pattern is a(n) _____ drawing of the object. stretchout. Sheet metal patterns are also known as _____. prism and cylinder . _____ and _____ are examples of the radial-line pattern development. Used to connect two differently shaped openings. What purpose does a transition piece serve? .

Oct 27, 2023 - Explore Shaun Wing's board "Sheet Metal Pattern Development" on Pinterest. See more ideas about sheet metal, sheet metal fabrication, sheet metal work.Pattern Development: Sheet Metal Level 1. Geometric Construction Introduction. As a sheet metal worker, we work with different lines, angles and shapes. We work with geometry. Be it in the field or in a shop, geometry is a tool we use in many different ways. From creating 2D patterns of 3D objects, to making sure roof panels are installed .

Sheet Lightning is unfolding software for designing and unwrapping pattern developments for sheet metal designs. It combines an integrated parametric library and a full 3D CAD design environment. The parametric design facility .From the shop drawing, create an end view of the fitting; In the end view, label each piece with the amount of “drop” it has; Look for the corner which appears as “dot”.The dot will show where a bend can occur and will have no slope . .Pattern Development: Sheet Metal Level 1. Geometric Construction. 1 Construct Triangles – “Triangulation” When the Three Lengths Are Known (3-4-5) Draw a line equal to one of the known lengths. Set your compass to the second known length (6 inches) and swing an arc from one end of the line (point A). Take a look at how we got started, before you can begin to layout your pattern you have to find all your true lengths. The only way you can see a true length line is perpendicular to its plane, the best way to see the true lengths in a square to round fitting is to draw a top view of the fitting as we did above.

Plate 'n' Sheet Development is a software program designed to unfold shapes commonly encountered by fabricators and sheet metal workers. Plate 'n' Sheet Development is a software program designed to unfold shapes commonly encountered by fabricators and Sheet Metal workers. The dimensions and other parameters that define the shape are entered by the . sheet metal drawing and pattern development by a. dickason. Publication date 1967 Publisher sir isaac pitman & sons ltd Collection internetarchivebooks; inlibrary; printdisabled Contributor Internet Archive Language English Item Size 1.2G . Access-restricted-item true

20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.

Development Pattern Construction: CONSTRUCTING DEVELOPMENT SHAPES WITH MATHEMATICS The construction of 3-D models from pieces from flat cardboard or thin sheet metal requires some mathematical and geometrical application. Starting with simple 3-D forms, we can calculate the shape of.Pattern Development: Sheet Metal Level 1. Parallel Line Pattern Development. 15 Equal Diameter 90 Degree Tee We can start to take some short-cuts in our drawing. Instead of drawing a full plan view, we will use profiles. You can always go back to drawing the full plan view!

Sheet Metal Pattern Development - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses different methods for developing sheet metal patterns from objects, including parallel line development, radial line development, and triangular development. It also covers fabricating edges, joints, seams, and notches in sheet metal.Pattern Development: Sheet Metal Level 1. Parallel Line Pattern Development. 16 Unequal Diameter 90 Degree Tee-Shop Method We will continue to use short-cuts. In this example, we move the views into the blank size and minimize our drawing. It still gives us the point “where the tee hits the pipe” and it is much more manageable to do in the .

Pattern development is used in sheet metal and packaging industries. In sheet metal, patterns are used to cut and form metal sheets into objects like ducts and pans through bending and fastening. In packaging, patterns allow designers to create durable and appealing boxes and containers that protect fragile contents. Patterns are surface .Pattern Development: Sheet Metal Level 1. Triangulation. 24 On-Centre Square to Round A square to round can only be formed in halves, so we always develop a half pattern. Draw a full plan view complete with all element lines and labeling. Label one half of the plan view, the round end with numbers and the square end with letters.

sheet metal layout software free

Laser cutting is a highly efficient and precise method for cutting various metals. The cutting speed and thickness capabilities of a laser cutter depend on several factors, including the laser power, type of metal, and material thickness.

sheet metal pattern development|free sheet metal layout patterns