sheet metal forming processes and applications In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. A favorite of cocktail enthusiasts, wine lovers, and beer drinkers alike, our 24" 1 Class Beverage Center is the smart choice for a home bar companion. This model is available with a stainless steel glass door, or with integrated panel-ready finish options.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Sheet Metal Forming: Processes and Applications covers all major sheet forming operations including blanking, bending, flanging, deep drawing, stamping, spinning, clinching, and crimping.This practical and comprehensive reference gives the latest developments on the .

Companies now leverage powerful applications like Autodesk’s Fusion 360 in modern manufacturing workflows. The advent of CAD and CAM have unlocked laser cutting — a precise sheet metal forming process that .In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling.This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual chapters cover all. Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

sheet metal working process pdf

What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products . This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equipment, tooling, and process modeling. Individual . Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end .

1. The different types of sheet metal forming processes such as bending, stretching, and deep drawing. 2. The materials used in sheet metal forming, including commonly used metals, alloys, and composites. 3. The .Roll forming is a continuous cold forming process that gradually shapes metal sheets into the desired form through a series of rotating rollers. During this process, the metal sheet moves continuously through a set of pre-designed .The aim of sheet metal forming is to produce parts made of thin sheet metal for utilization in a diverse range of applications. Sheet metal forming is an extremely flexible process that exploits the strength and ductility of sheet metal to create long-lasting parts, which are more cost-effective compared to similar manufacturing processes like .These challenges have caused a need for developing manufacturing processes in general, including obviously those devoted in particular to the development of thin-walled metallic shapes, as is the case with tubular and sheet metal parts and devices.This Special Issue is thus devoted to research in the fields of sheet metal forming and tube .

Forming is the most widely used sheet metal operation used for manufacturing various sheet metal components across the industry.. Sheet Metal Forming . Image courtesy: Wiki Based upon the manufactured components and the manufacturing process, various kinds of forming are developed.. Different types of sheet metal forming processes and their .Semantic Scholar extracted view of "SHEET METAL FORMING: Processes and Applications" by M. O. Görtan et al. Skip to search form Skip to main content Skip to . @inproceedings{Grtan2012SHEETMF, title={SHEET METAL FORMING: Processes and Applications}, author={Mehmet Okan G{\"o}rtan and Haydar Livatyali and Peter Groche}, . There’s no denying that sheet metal plays a pivotal role in projects across numerous industries. Sheet metal is commonly fashioned from steel or aluminum and typically takes a thin and flat form. Despite this, sheet metal alterations are commonplace — and essential — depending on the application in question. This is where the forming of sheet metal parts .

In this context, we are pleased to invite you to contribute to this Special Issue dealing with recent studies in the field of tube and sheet metal forming processes and their main applications within different high-tech industries, such as the aerospace, the automotive or the medical sectors, among others. Assoc. Prof. Gabriel Centeno BáezThese challenges have caused a need for developing manufacturing processes in general, including obviously those devoted in particular to the development of thin-walled metallic shapes, as is the case with tubular and sheet metal parts and devices.This Special Issue is thus devoted to research in the fields of sheet metal forming and tube .

This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and galvanized steel. . Applications of Sheet Metal Forming. Sheet metal forming’s disadvantages aren’t enough to .

This chapter discusses the use of modeling and simulation technology in the development of sheet metal forming processes. It describes the five major steps involved in finite-element analysis and the various ways functions of interest can be approximated at each point or node in a .Sheet Metal Forming: Processes and Applications. Edited by Taylan Altan; Taylan Altan Search for other works by this author on: This Site. Google Scholar. A. Erman Tekkaya . Soumya Subramonian, Blanking, Sheet Metal Forming: Processes and Applications, Edited By Taylan Altan, A. Erman Tekkaya, ASM International, 2012, p 1–17, .This chapter presents two case studies; one demonstrating the use of finite-element analysis (FEA) in the design of a progressive die forming operation, the other explaining how software simulations helped engineers reduce thinning and eliminate cracking and deformation observed in clutch hubs formed using a three-step transfer die process.

Sheet Metal Forming: Processes and Applications, Edited By Taylan Altan, A. Erman Tekkaya, ASM International, 2012. Download citation file: Ris (Zotero) . Sheet Metal Forming Processes and Applications. Preface. Sheet Metal Forming Fundamentals. Cold and Hot Forging Fundamentals and Applications. Related Topics. university. taylan. state. The sheet forming process includes operations like cup drawing, stamping, stretching, bending, ironing, spinning etc. that can be performed by many forming techniques using die, punch, blank holder and other tools. The purpose of process design is to predict and design the sheet forming process at the ‘design stage’ of a component . Sheet Metal Roofing: Cold forming techniques, such as roll forming and bending, are employed to fabricate sheet metal roofing panels and flashings. Pipes and Tubes : Extrusion and drawing processes manufacture .Explore the intricate process of sheet metal forming, its applications in various industries, and the distinction between sheet and plate metal. Learn about the manufacturing processes, the challenges with plate metal, and the final .

Table 1: Materials used in sheet metal forming.. When selecting sheet metal materials for forming, the following factors are considered. Formability – Generally, materials with higher elongation percentage have better .Sheet metal spinning is a forming technique that produces axially symmetric hollow bodies with nearly any contour. It is often used in combinatio . L. Kwiatkowski, Spinning, Shear Forming, and Flow Forming, Sheet Metal Forming: Processes and Applications, Edited By Taylan Altan, A. Erman Tekkaya, ASM International, 2012, p 249–272, https .This chapter describes a sheet metal forming method, called hydroforming, that uses pressurized liquid and a shaped punch or die. It discusses the advantages and disadvantages of the two approaches, the effect of process variations, and tooling modifications intended to . Analysis and Optimization of Sheet Metal Forming Processes comprehensively covers sheet metal forming, from choosing materials, tools and the forming method to optimising the entire process through finite element analysis and computer-aided engineering.. Beginning with an introduction to sheet metal forming, the book provides a guide to the various .

PDF | Metal Forming Processes, Bulk forming,Sheet metal forming | Find, read and cite all the research you need on ResearchGate. . Application to Virtual Metal Forming. February 2013.Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) . describe different forming processes, when they might

Edited by Taylan Altan and A. Erman Tekkaya ASM International® Materials Park, Ohio 44073-0002 www.asminternational.org Sheet Metal Forming FUNDAMENTALS Types of Sheet Metal Forming Processes. Forming sheet metal is a genuinely versatile process. In addition to the many techniques you can use to achieve varying results, there are also different types of metal forming. Each type has its unique characteristics, which can influence the choice of a specific process depending on the desired outcome.

sheet metal stamping process pdf

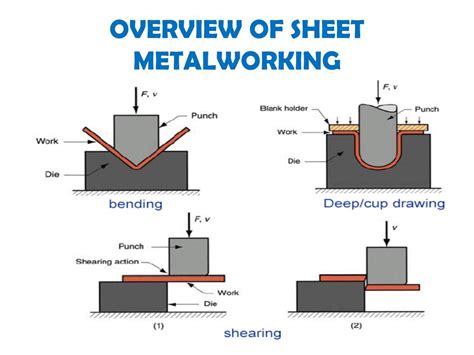

3. Syllabus Sheet metal characteristics – shearing, bending and drawing operations – Stretch forming operations – Formability of sheet metal – Test methods –special forming processes-Working principle and applications – Hydro forming – Rubber pad forming – Metal spinning– Introduction of Explosive forming, magnetic pulse forming, peen forming, . Sheet Metal Forming Processes; Power metal forming process; Bulk Forming Processes. Bulk forming process involves using raw materials with a low surface area to volume ratio for shaping. This category includes processes like rolling, forging, extrusion, and drawing. . Applications of Metal Forming Processes across Industries include the .

Application of high-order NURBS functions leads to high computational costs, according to [16]. . One of the most important challenges in sheet metal forming processes is to predict the feasibility of the production which depends on numerous parameters such as the initial blank and friction conditions. During the recent years, these .

sheet metal processes pdf

sheet metal forming process pdf

3 axis cnc billet cool part

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

sheet metal forming processes and applications|sheet metal bending process pdf