cnc part programming pdf Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

OEM ODM CNC machining service since 1999. aluminum,brass,stainless steel cnc machining parts manufacturer Computer Numerical Control (CNC) machining is a highly accurate and efficient method for cutting, milling, and drilling aluminum parts.

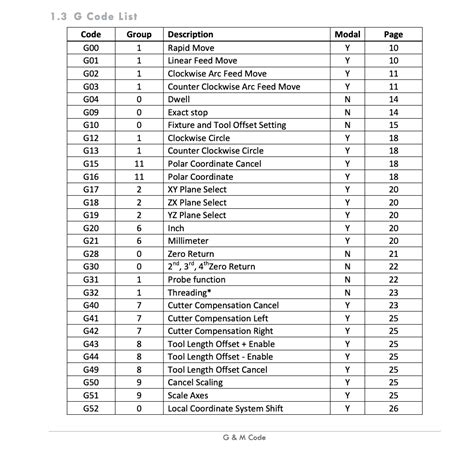

0 · g code m list pdf

1 · fanuc cnc milling programming pdf

2 · fagor cnc programming examples

3 · cnc turning program examples pdf

4 · cnc turning cycle program pdf

5 · cnc programming examples with drawing

6 · cnc programming codes pdf

7 · cnc part programming examples pdf

Order high precision CNC machining parts online with flexibility and certainty. ISO 9001 and 13485 Certified! Access a wide range of precision machining capabilities through our global network of manufacturing partners. 3, 4 and 5 .

200 Madison Avenue, New York, NY 10016. CONTENTS. Preface. The term numerical control is a widely accepted and commonly used term in the machine tool industry. Numerical control .The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the .

basic concepts of manual part programming who prepares the tape / cd ? –programmer –> should be familiar with the manufacturing processes. optimal sequence of operations should be .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and . Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

The examples described in this manual are for learning purposes. Before using them in industrial applications, they must be properly adapted making sure that the safety regulations are fully .TABLE OF CONTENTS. 1 - NUMERICAL CONTROL 1. DEFINITION OF NUMERICAL CONTROL . . . 1. NC and CNC Technology . . . . . . . . . . . . . 1. CONVENTIONAL AND CNC .CNC Lathe Programming. Prof. Steven S. Saliterman Introductory Medical Device Prototyping. Department of Biomedical Engineering, University of Minnesota http://saliterman.umn.edu/ .

All CNC machining begins with a part program, a sequential instructions or coded commands that direct the specific machine functions. Part program may be manually generated or, using .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.machine tools in CNC have enabled industry to consistently produce parts to accuracies undreamed of only a few years ago. The same part can be reproduced to the same degree of accuracy any number of times if the CNC program has been properly pre-pared and the computer properly programmed. The operatingpdf of noc16_me21 week 1: 320: Week 1: noc18_me06 week 1: pdf of noc18_me06 week 1: 317: . Questions on Programming and Interpolation: Download Verified; 16: Lecture 16 : 3-D Machining - Basic Concepts : Download . Lecture 19 : Cutter Path Generation (Concluding Part) and Current Status - CNC Machining and Related Processes: Download ; 20 .

Rather, it is to show how to use CNC to make common types of parts, teachDFM principles, and help engineersbecome better designers and managers. . program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks.Computer-Assisted Part Programming • In computer-assisted part programming (APT), the machining instructions are written in English-like statements that are subsequently translated by the computer into the low-level machine code that can be interpreted and executed by the machine tool controller. • When using one of the part programming languages, the two main .

The CNC Part Programming Workbook contains 15 learning assignments, each with a number of carefully chosen and structured tasks which will develop the skills needed to work from engineering drawings of components which are to be machined and to produce part programs which incorporate the various commands and functions of a CNC system. Part programming for CNC machine. Part programming is a program done for the production of a component by using standard codes known as the part program. Code is nothing but the name of a program written for producing standard movement of the tool. G-codes: These are the general-purpose codes. Some of the G codes with their purpose are: CNC part programming pdf is considered to handle complex designs with greater speed and accuracy. It also has an edge over manual machining when manufacturers require repeated production in less time. In addition, part programming provides flexibility in work and allows the milling of contoured shapes, such as those created in 3D designs. .CNC Lathe & Part Programming by P rof. Jitendra Kumar Lecturer ,Department of Mechanical Engineering G P Vaishali Bihar-844118. . Part program proving. CNC programming .

CNC Part Programming - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document discusses CNC part programming. It begins by explaining the fundamentals of machining and how part programs define the relative motion of cutting tools and workpieces using reference directions and coordinate systems.CNC PART PROGRAMMING.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document describes developing part programs for CNC turning, milling, and verifying on simulation software. It involves: - Co-developing part programs that control machine tool movement and auxiliary functions to . Cnc milling programs - Download as a PDF or view online for free. Submit Search. . To prepare a CNC part program to mill the component as per the drawing Assume thickness = 20mm 100 80 40 40 12050 40 50 50 20 20 SIMULATION MODEL:- 2. ABSOLUTE MODE(G90) .

electro harmonix voice box review harmony central

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

g code m list pdf

workbook may apply in whole or in part to the programming of other CNC machines. It is intended to give a basic understanding of CNC programming and it’s applications. It is not intended as an in-depth study of all ranges of the machine use, but as an overview of common and potential situations facing CNC programmers. Much more training and

CAD/CAM [ Draw the part, Cutter path is generated] oOffline programming linked to CAD programs. oConversational programming by the operator. oMDI ~ Manual Data Input. oWord-Address Coding using standard G-codes and M-codes. Basics of NC Part Programming: During secondary motion either the tool motion, moves relative to the workpiece or theVirtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NCDownload Free PDF. SOLUTIONS FOR PROBLEMS ON NC PART PROGRAMMING. Sunny Goel. . Prepare a part program for machining a rectangular contour of 200 mm x 150 mm size from a suitable blank of 5mm .

electro harmonix voice box demo

This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of G-Code programming already, as this is essential before learning the advanced programming techniques provided by the macro language. Section 1. What is macro programming Computer assisted part programming • The manual part programming is a time consuming process and needs an expert part programmer who should have through knowledge of the various machining processes, materials, speeds and feeds, part programming codes and capabilities of various machine tools, etc. • Modern NC/CNC machines where more than . CNC PROGRAMMING BASICS • CNC instructions are called part program commands. • When running, a part program is interpreted one command line at a time until all lines are completed. • Commands, which are also referred to as blocks, are made up of words which each begin with a letter address and end with a numerical value.Hurco Hardware Installation Procedure for Ultinet Networking Option. 6 pages. x

CNC PART PROGRAMMING (MILLING) PART 1 Generate manual part program for the part shown in Figure 1 for NUM Flexium 68. The cutting conditions are as follows: Cutting tool diameter: 12 mm Spindle speed: 1000 rpm (use M43 S1000) Note: M43 is used to specify the spindle speed range. Feedrate: 2.5 mm/sec The format of the CNC part program should be .• prepare CNC part program for milling, and • prove the part program. 6.2 EXAMPLES Example 6.1 The component to be machined is shown in Figure 6.1. Prepare a CNC part program to machine the holes on vertical axis CNC machining center using the ISO standard G-codes. You may choose Program Zero (Axes) to be used for the component.Course Objectives: CLO1 To expose the students to the techniques of CNC programming and cutting tool path generation through CNC simulation software by using G-Codes and M-codes CLO2 To educate the students on the usage of CAM packages and cut part on virtual CNC machine simulator. CLO3 To make the students understand the importance of automation in .controlling the part programming, and • description of some common miscellaneous or M codes that are used in most of the CNC machine tools. 4.2 PART PROGRAMMING FUNDAMENTALS As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically a

The features of CNC machines are as follows: Part program input may be through the keyboard. The part program is entered into the computer and stored in the memory. Then it is used again and again. The entered part program can be edited for any errors or design changes.Each part trajectory was programmed using a drawing that includes all the distances, radii and intersection points required by the NC program. To generate a NC part program in the machine controller, the authors looked for the easiest way, as technicians normally do. Nested cycles with sub-routines that include the M97 code were used.

fanuc cnc milling programming pdf

Wholesale CNC milling cutter manufacturers play a crucial role in supplying these cutting tools to businesses worldwide, enabling them to execute intricate designs, improve efficiency, and ensure high-quality output.

cnc part programming pdf|fagor cnc programming examples