26 gauge sheet metal vs 29 26 vs 29 gauge metal roofing. When comparing 29 vs 26 gauge metal roofing, consider the following factors: Thickness: 26 is thicker than 29. The thickness of a 26-gauge roof is approximately 0.0188 inches, while a 29-gauge roof . The range of a circuit breaker is a critical parameter that determines its maximum current carrying capacity. Choosing the right range ensures that the circuit breaker provides effective protection against overcurrent, short circuits, and other electrical faults.

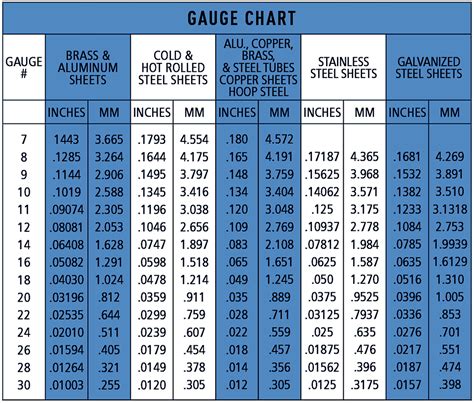

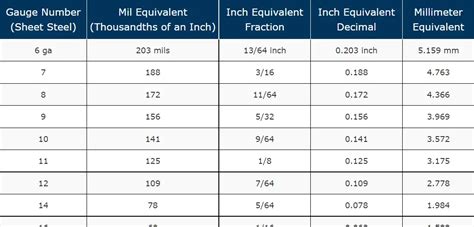

0 · metal roofing gauges chart

1 · metal roofing conversion chart

2 · corrugated metal gauge chart

3 · carports 26 gauge vs 29

4 · 29 gauge vs 26

5 · 29 gauge metal roofing thickness

6 · 29 gauge metal roofing reviews

7 · 26 gauge metal roofing thickness

Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the .

This article will explain the difference between 26 vs. 29-gauge metal roofing. It will also detail some of the different materials your new metal roof can be made out of, as well as the . Choosing between 26 gauge and 29 gauge sheet metal depends on the specific requirements of your project, including durability, strength, and budget considerations. While 26 gauge offers greater thickness and strength, .

Discover the pros and cons of 22, 24, 26, and 29 gauge metal roofs, as well as their differences, to help you determine which option best suits your needs. What is better, 26-gauge or 29-gauge roofing? Choosing 26-gauge vs. 29-gauge roofing depends on your needs and the kind of structure you are building. 26-gauge steel is .26 vs 29 gauge metal roofing. When comparing 29 vs 26 gauge metal roofing, consider the following factors: Thickness: 26 is thicker than 29. The thickness of a 26-gauge roof is approximately 0.0188 inches, while a 29-gauge roof .

Union Corrugating Company manufactures metal roofing in 29, 26 and 24 gauges. The company indicates that 29-gauge metal is the thinnest metal that's recommended for use on homes. Neither 29- nor 26-gauge metals may .In this system, the lower the numbered caliber, the thicker the sheet of metal. A 22 GA. is much thicker than a 29 GA. This is important for roofing because the thicker the metal, the more structural integrity it provides – the less likely to be .The main difference between 26 vs 29 gauge roofing is the thickness of the metal. 26 gauge is about 0.02 inches thicker than 29 gauge, so that it will cost more per square foot of coverage. This means a 26 gauge roof will cost about 10-15% . When it comes to 26 vs. 29, 26-gauge is the thicker metal. Most homes in residential areas use 29-gauge metal panels. The weight of 29-gauge metal roofing may differ, though, depending on the type of metal that you choose.

In this article, we analyze which panel provides the most value by comparing 26 gauge vs 29 gauge steel in the following areas: 1. Durability Of 26 Gauge Vs. 29 Gauge Roofing. Panels in both size gauges provide the durability benefits of metal. They are fire-resistant, low maintenance, and protect against corrosion.This article will explain the difference between 26 vs. 29-gauge metal roofing. It will also detail some of the different materials your new metal roof can be made out of, as well as the advantages and disadvantages of these materials.

Choosing between 26 gauge and 29 gauge sheet metal depends on the specific requirements of your project, including durability, strength, and budget considerations. While 26 gauge offers greater thickness and strength, 29 gauge can still provide satisfactory performance for lighter applications. Discover the pros and cons of 22, 24, 26, and 29 gauge metal roofs, as well as their differences, to help you determine which option best suits your needs. What is better, 26-gauge or 29-gauge roofing? Choosing 26-gauge vs. 29-gauge roofing depends on your needs and the kind of structure you are building. 26-gauge steel is thicker than 29-gauge steel and provides more protection against external elements such as weather and insects.

26 vs 29 gauge metal roofing. When comparing 29 vs 26 gauge metal roofing, consider the following factors: Thickness: 26 is thicker than 29. The thickness of a 26-gauge roof is approximately 0.0188 inches, while a 29-gauge roof measures around 0.0142 inches. Union Corrugating Company manufactures metal roofing in 29, 26 and 24 gauges. The company indicates that 29-gauge metal is the thinnest metal that's recommended for use on homes. Neither 29- nor 26-gauge metals may be the best option if you live in an area that's prone to high winds and severe weather conditions.

In this system, the lower the numbered caliber, the thicker the sheet of metal. A 22 GA. is much thicker than a 29 GA. This is important for roofing because the thicker the metal, the more structural integrity it provides – the less likely to be damaged by impact or .The main difference between 26 vs 29 gauge roofing is the thickness of the metal. 26 gauge is about 0.02 inches thicker than 29 gauge, so that it will cost more per square foot of coverage. This means a 26 gauge roof will cost about 10-15% more than a 29 gauge roof. When it comes to 26 vs. 29, 26-gauge is the thicker metal. Most homes in residential areas use 29-gauge metal panels. The weight of 29-gauge metal roofing may differ, though, depending on the type of metal that you choose.

metal roofing gauges chart

In this article, we analyze which panel provides the most value by comparing 26 gauge vs 29 gauge steel in the following areas: 1. Durability Of 26 Gauge Vs. 29 Gauge Roofing. Panels in both size gauges provide the durability benefits of metal. They are fire-resistant, low maintenance, and protect against corrosion.This article will explain the difference between 26 vs. 29-gauge metal roofing. It will also detail some of the different materials your new metal roof can be made out of, as well as the advantages and disadvantages of these materials.

10 foot galvanized steel 4 inch box type downspout

Choosing between 26 gauge and 29 gauge sheet metal depends on the specific requirements of your project, including durability, strength, and budget considerations. While 26 gauge offers greater thickness and strength, 29 gauge can still provide satisfactory performance for lighter applications. Discover the pros and cons of 22, 24, 26, and 29 gauge metal roofs, as well as their differences, to help you determine which option best suits your needs.

What is better, 26-gauge or 29-gauge roofing? Choosing 26-gauge vs. 29-gauge roofing depends on your needs and the kind of structure you are building. 26-gauge steel is thicker than 29-gauge steel and provides more protection against external elements such as weather and insects.26 vs 29 gauge metal roofing. When comparing 29 vs 26 gauge metal roofing, consider the following factors: Thickness: 26 is thicker than 29. The thickness of a 26-gauge roof is approximately 0.0188 inches, while a 29-gauge roof measures around 0.0142 inches. Union Corrugating Company manufactures metal roofing in 29, 26 and 24 gauges. The company indicates that 29-gauge metal is the thinnest metal that's recommended for use on homes. Neither 29- nor 26-gauge metals may be the best option if you live in an area that's prone to high winds and severe weather conditions.In this system, the lower the numbered caliber, the thicker the sheet of metal. A 22 GA. is much thicker than a 29 GA. This is important for roofing because the thicker the metal, the more structural integrity it provides – the less likely to be damaged by impact or .

The main difference between 26 vs 29 gauge roofing is the thickness of the metal. 26 gauge is about 0.02 inches thicker than 29 gauge, so that it will cost more per square foot of coverage. This means a 26 gauge roof will cost about 10-15% more than a 29 gauge roof.

metal roofing conversion chart

corrugated metal gauge chart

What Is a Junction Box Used For in Commercial Applications? A junction box is an electrical enclosure that houses one or more wiring connections. The box protects the connections, which usually contain vulnerable points such as wire splices, from environmental conditions and accidental contact.

26 gauge sheet metal vs 29|metal roofing gauges chart