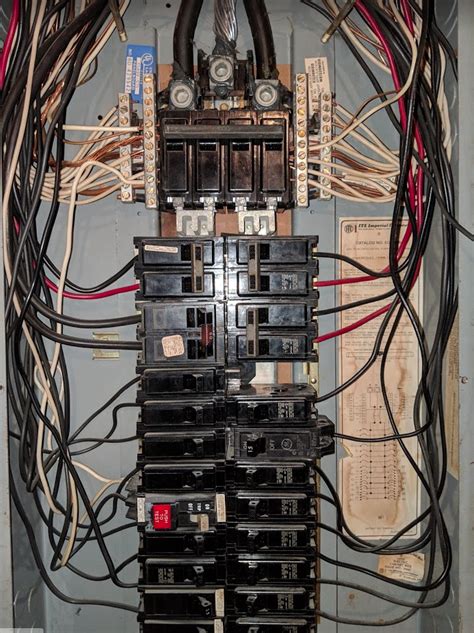

electrical box too corroded bus bar Electrical - AC & DC - Corrosion on circuit breaker contacts - I had some lights flickering, so I went to the breaker box, and I could hear quiet buzzing/crackling. I pulled the . We are a trusted used machinery dealer serving Michigan since 1985. With over 30 years experience in the used machinery industry selling to customers in Michigan MI as well as nationally and internationally, we can help you find the used machinery, machine tools or used CNC's you are looking for.

0 · repair busbar contact

1 · corrosion in bus bar

2 · buss bar oxidation problems

3 · busbar repair problems

4 · busbar problems with contacts

5 · busbar problems

6 · busbar corrosion

7 · bus bar load breaker

Lathes & Turning Machines - CNC Lathes for sale listings - We have 2095 listings for CNC Lathes listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. For more information on an item, contact the seller directly.

repair busbar contact

Taking the cover off my electrical panel, I notice white flakes primarily on the hot bus bar just after the main breaker and under some of the individual breakers. the service to the house was replaced about 15 years or so. found that water had been leaking into the panel for several years and causing oxidation on the busses and neutral . An example of corrosion forming at aluminum bus bars, along with rust stains, is shown below. Anti-oxidant paste is required to be applied over exposed aluminum wire at . The contact isn't corroded. It is destroyed. The arcing removed metal from the contact. The metal is gone, and cannot be restored. That slot is done for and you will not be fitting breakers there anymore. Your best bet is to .

Electrical - AC & DC - Corrosion on circuit breaker contacts - I had some lights flickering, so I went to the breaker box, and I could hear quiet buzzing/crackling. I pulled the . how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d. We were prohibited from doing any work on the panel once we discovered burning or pitting on the bus bar. We removed the damaged breaker and advised the homeowner that .

Check the incoming lugs for proper voltage. If correct call an electrician. If not call BGE. Answers based on the National Electrical Code. Local amendments may apply. Check .Does anybody have a recommendation for cleaning the corrosion off of this part of the bus bar? Beyond sandpaper on a Dremel I wouldn't know where to start. The panel is a Siemens Q . least cost will be to purchase indoor loadcenter that has same interior and swap the interior - if you can find one. Looks like design they still use so it may be possible. Breaker . Taking the cover off my electrical panel, I notice white flakes primarily on the hot bus bar just after the main breaker and under some of the individual breakers.

the service to the house was replaced about 15 years or so. found that water had been leaking into the panel for several years and causing oxidation on the busses and neutral along with rust on the load side branch breakers, main breaker and main breaker buss bar ties. An example of corrosion forming at aluminum bus bars, along with rust stains, is shown below. Anti-oxidant paste is required to be applied over exposed aluminum wire at connection lugs in a panel. But, if that is not done or excessive moisture attacks the aluminum, the wiring can overheat and start a fire. The contact isn't corroded. It is destroyed. The arcing removed metal from the contact. The metal is gone, and cannot be restored. That slot is done for and you will not be fitting breakers there anymore. Your best bet is to plug the hole with something.

Electrical - AC & DC - Corrosion on circuit breaker contacts - I had some lights flickering, so I went to the breaker box, and I could hear quiet buzzing/crackling. I pulled the breaker (type EQ-P), and the buss bar was badly corroded, as was the contacts on the breaker. how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d.

We were prohibited from doing any work on the panel once we discovered burning or pitting on the bus bar. We removed the damaged breaker and advised the homeowner that the panel had to be replaced, as required by code.

Check the incoming lugs for proper voltage. If correct call an electrician. If not call BGE. Answers based on the National Electrical Code. Local amendments may apply. Check with your local building officials. They should be checked with a load. Start by flipping the main off/then on and recheck voltage before and after the main breaker.

Does anybody have a recommendation for cleaning the corrosion off of this part of the bus bar? Beyond sandpaper on a Dremel I wouldn't know where to start. The panel is a Siemens Q Series. Sound like the bus bar could be damaged and not just corroded. I would try sandpaper 1st but not with a dermal. You might cause more damage with it.

least cost will be to purchase indoor loadcenter that has same interior and swap the interior - if you can find one. Looks like design they still use so it may be possible. Breaker that was plugged onto the problem spot also needs replaced or it will fail again. Taking the cover off my electrical panel, I notice white flakes primarily on the hot bus bar just after the main breaker and under some of the individual breakers. the service to the house was replaced about 15 years or so. found that water had been leaking into the panel for several years and causing oxidation on the busses and neutral along with rust on the load side branch breakers, main breaker and main breaker buss bar ties. An example of corrosion forming at aluminum bus bars, along with rust stains, is shown below. Anti-oxidant paste is required to be applied over exposed aluminum wire at connection lugs in a panel. But, if that is not done or excessive moisture attacks the aluminum, the wiring can overheat and start a fire.

The contact isn't corroded. It is destroyed. The arcing removed metal from the contact. The metal is gone, and cannot be restored. That slot is done for and you will not be fitting breakers there anymore. Your best bet is to plug the hole with something.

corrosion in bus bar

Electrical - AC & DC - Corrosion on circuit breaker contacts - I had some lights flickering, so I went to the breaker box, and I could hear quiet buzzing/crackling. I pulled the breaker (type EQ-P), and the buss bar was badly corroded, as was the contacts on the breaker. how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d.

We were prohibited from doing any work on the panel once we discovered burning or pitting on the bus bar. We removed the damaged breaker and advised the homeowner that the panel had to be replaced, as required by code. Check the incoming lugs for proper voltage. If correct call an electrician. If not call BGE. Answers based on the National Electrical Code. Local amendments may apply. Check with your local building officials. They should be checked with a load. Start by flipping the main off/then on and recheck voltage before and after the main breaker. Does anybody have a recommendation for cleaning the corrosion off of this part of the bus bar? Beyond sandpaper on a Dremel I wouldn't know where to start. The panel is a Siemens Q Series. Sound like the bus bar could be damaged and not just corroded. I would try sandpaper 1st but not with a dermal. You might cause more damage with it.

18 gauge vs 22 gauge sheet metal

There are two types of fireboxes that rule the fireplace world: pre-fab metal fireboxes and masonry fireboxes. Pre-Fab Metal Fireboxes. OWS Capri Cast Stone Fireplace. Gas fireboxes are a reliable way to provide consistent heat .

electrical box too corroded bus bar|busbar problems with contacts