cnc machine swarf removal Efficient swarf removal offers several benefits, including: Enhanced tool life: Removing swarf promptly reduces tool wear, allowing for longer tool life and ensuring consistent machining . What are keys made of? In history, keys have been made using different materials including very unorthodox ones like fortified animal bones. But conventionally, keys are made from various types of metals which include .

0 · swarf removal techniques

1 · swarf metalworking

2 · swarf machine safety

3 · swarf equipment safety

4 · swarf equipment

5 · how to handle swarf

6 · cnc swarf washdown

7 · cnc swarf removal

Learn what size electrical box screws you need for your next project with our handy guide. We'll cover everything from standard sizes to metric measurements, so you can .

Efficient swarf removal offers several benefits, including: Enhanced tool life: Removing swarf promptly reduces tool wear, allowing for longer tool life and ensuring consistent machining . In this article, we'll explore how efficient swarf handling can drastically reduce machine downtime. You'll learn about best practices, practical solutions, and strategies to streamline swarf management, ultimately boosting . Gio Albanese: Ben, today we're going to take a closer look at your Swarf Management Systems and conveyors and the innovation behind them, and how they've evolved over the years. Ben Crowther:.

Swarf removal for Vertical CNC machines demo in Haas VF4SS. .more.

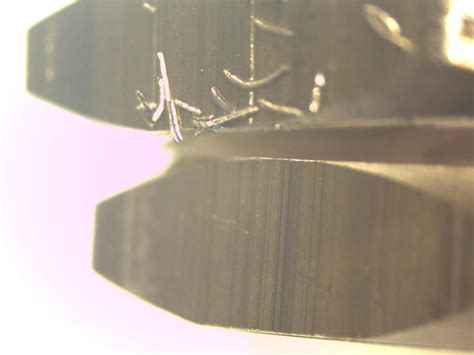

In this blog post, we'll explore the importance of having an efficient swarf removal system in place and how it can streamline CNC machine efficiency. We'll discuss the types of swarf removal . Boring process needs to be stopped and stringy nest of swarf removed every 15" of boring depth. The operator goes in with a hooked stick and fishes out the swarf. Has anyone . This video will add value to the knowledge of Diploma/ Engineering students in regards to swarf removal in CNC machines.

The Swarf Unlimited All-In-One Conveyor is the ultimate solution to your CNC machine swarf removal needs! This powerful conveyor is equipped with advanced features that ensure a clean and efficient production process. Ben discusses the benefits of the new Cromar Swarf Management Technologies and Products. Gio Albanese: Ben, today we're going to take a closer look at your Swarf .Introducing our Ultra High Performance Swarf Removal Tool – a game-changer for removing swarf from your Swarf Unlimited sump filters. The scraper effortlessly lifts swarf without damaging your filter screen. Built for durability, the shovel .The Clean•Tec, “The Original” Chip Fan cleans the machine interior after machining processes, removing chips and coolant without the operator having to open the machine tool door. As a final step in the machining process, the Chip .

There are also a wide range of belts to maximise swarf removal and coolant drainage. The HB is best choice for coarse and stringy swarf applications, where filtration is not essential to machining quality. In addition to saving labour and .

swarf removal techniques

Oh, Diamond Machiners are notorious for taking their machines to bits and tinkering with them. be careful if you leave the enclosures off when machining Aluminium as the swarf conducts electricity and can short out boards etc. Anyways! nice to meet you Aid with removal of swarf and used coolant from your CNC machines in a cost effective and time saving manner. Full-Service Cleaning of CNC Machines to Maintain High Performance. . Our service begins with advanced vacuum removal of all liquids, metal shavings, and other contaminants. Utilizing our fleet of 3,800-gallon vacuum trucks equipped .

solidworks 2015 sheet metal box

GM Meccanica performs various processes by light alloys swarf removal with CNC 5-axis milling machine with working areas up to 6m long for a linear width of 0.6mt. The technology of the light alloys swarf removal sector also includes: - 3 fresatrici CNC 5 assi campo di lavoro 6×0.6ml. – Fresatrice CNC 3 assi campo di lavoro 6×0.6ml. Cleaner and better performing machine pumps avoiding blockages and expensive machine downtime; Tank cleaning with sludge and swarf removal; Cost savings for emulsion buy-back; Saving on waste recovery (in case of brass machining) Reduce machine downtime by speeding up cleaning operations; Reuse of refrigerants, thus avoiding disposal and .Why Swarf Removal Matters . Swarf removal is essential for several reasons. Firstly, it helps to prevent damage to the CNC machine. Swarf can accumulate in a machine's nooks and crannies, causing clogs and potentially damaging mechanical components. Secondly, efficient swarf removal increases productivity by reducing downtime for cleaning and .

Tiger-Vac manufactures a full line of industrial vacuum systems designed to meet the diverse needs of the metalworking and machine shop industry. From the recovery of coolants and lubricants, collection of small debris, metal chips, to the cleanup of lathes and cutting and grinding machines, Tiger-Vac has the right CNC chip vacuum to clean your shop. Our industrial .Haas CNC Chip Clearing Fans are the perfect complimentary tools for all CNC users, big and small, for short runs or production. They are engineered to provide the best results possible, when it comes to removing machined material chips, coolant, and other debris from your workpiece or fixture. . (if the machine is equipped) to pre-clean large . Most industrial processes involve swarf removal machining at some stage of their development. For this reason, this technique is widely used in industry. The military and aeronautical industries are usually two large sectors .

swarf metalworking

Cromar are a major European manufacturer of Swarf Conveyors and Filtration solutions for the engineering, aerospace and rail industries, and also offer conveyor spare parts and a conveyor repairs service. The Slat/Hinge conveyor is a general purpose swarf conveyor .A quick and easy way to remove coolant and swarf chips from your work piece and table before opening the machine door. Supplied with 2 coolant holes to support the removal of chips when required. Perfect addition to support an unmanned automation setup.

Accumulated shavings in a machine can cause issues like overheating, contamination, and potentially be a fire hazard. Conveyors, vacuums, or blowers help with chip removal. The metal shavings can be stored safely in bins, bags, or containers, awaiting recycling. . As these industries continue to use CNC, swarf will continue to have immense . Looking to upgrade our process for changing over coolant sumps. Our current methods suck, and induce thoughts of suicide. I have 8 machines, 4 of which have 100+ gallon tanks. We are shopping coolant sump vacuums, and would like to hear what you kind fellers are currently using with some.

Okay running into the cooling/SWARF problem and looking at options and they are as follows: Designing a plate to go on the machine to allow SWARF being directly sucked up and hoping the air flow provides some indirect air cooling (not the best option but gets swarf out of the way). Getting input on designing a compressor based (type to be determined within a budget) .

Jorgensen Conveyors offers the most comprehensive line of engineered conveyor solutions for your machine tool chip removal application.Contact us at 262-242-3089Chips or dust generated in the machining chamber (22) of a machine-tool (12) are removed by a current of suction air. The chamber is encapsulated airtight, the current (27) being directed in bundled form across it. The current can be inclined downwards from the top, and compressed-air can also be directed at the machining position roughly in the same direction as the suction .

swarf machine safety

solar panel mounting bracket for metal roofs

soldadura en frio para metal home depot

Mouras understood the importance of what he had stumbled on. After all, the treatment of human waste had not changed much since the middle ages. Even in Paris the . See more

cnc machine swarf removal|swarf equipment