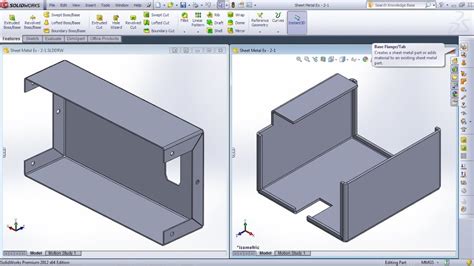

how to convert part to sheet metal in solidworks “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal . $29.99

0 · solidworks sheet metal pdf

1 · solidworks sheet metal drawing pdf

2 · solidworks convert to sheetmetal

3 · solid sheet metal

4 · sheet metal command in solidworks

5 · rip solidworks

6 · rip sketches

7 · how to sheet metal solidworks

$30.00

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. To convert a solid part to a sheet metal part: Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > .You can create a sheet metal part by converting a solid or surface body using .To convert an imported sheet metal part: Import the part. Click Convert to Sheet .Converting an Imported Part to a Sheet Metal Part. You can convert any .

“Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal .

The Convert to Sheet Metal command lets you specify the thickness, bends, and .

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. In this tutorial, we’ll guide you through the process of converting a part model into sheet metal in SolidWorks. 🛠️ Sheet metal conversion is essential for designs that need to be.

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .To convert an imported sheet metal part: Import the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . In the PropertyManager, under Sheet Metal Parameters, select the fixed face. .Converting an Imported Part to a Sheet Metal Part. You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet .

“Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part . Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. .The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. To convert a solid part to a sheet metal part: .It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.

How to Convert to Sheet Metal in SOLIDWORKS. Designing sheet metal parts from scratch in SOLIDWORKS can be a time-consuming and frustrating process, but it doesn’t have to be. Here are two methods that will . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . I have to delete the sheet metal feature from the tree and then convert the part to sheet metal. When doing this, I don't see a way to select the face on the 'inside' of the split line. Executing the feature then eliminates that entire interior zone.

This video shows the difference between creating a sheet metal part from scratch and converting a solid part to sheet metal.For more information about SOLIDW.

https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials, We Provide SolidWorks, .

To add a body to a sheet metal part using Convert to Sheet Metal: In a sheet metal part, select or create a plane and draw a sketch. Extrude the sketch. Click Convert to Sheet Metal (Sheet Metal toolbar) . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. . In this tutorial, we’ll guide you through the process of converting a part model into sheet metal in SolidWorks. 🛠️ Sheet metal conversion is essential for .

cnc machine vice

So I'm doing this as a sheet metal part, so that I can flatten my curved surfaces. Which is fine. I've used sheet metal parts to create corrugated boxes, etc. But I'm stuck here. The top of my pedal car is flat and tapers off in the back. That's all good. The bottom has the same taper but curves up towards the back. All good here too.In in this session, you will see how to:- convert simple solid geometry,- use the Solid to Sheet Metal tool, the Flange tool,- represent the look of a produc.

Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export Dxf files to other applications, such as punch press or laser-cutter programming software. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness .Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Version: SOLIDWORKS 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.If the cut feature outline isn't present on the side of the part you've selected as the Fixed Entity in Convert to Sheet Metal, it won't be transferred to the Sheet Metal part. That's also the case with countersunk and counterbored holes, convert sheet metal will transfer the outline that is on the fixed face to the sheet metal part.

You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. The imported part must be a constant thickness. If the part you are converting has a formed feature, the formed feature is deleted. You can reapply the feature after the conversion. Learn how to convert a solid part and surface body parts into sheet metal. Explore our library of SOLIDWORKS tutorials today: https://www.solidprofessor.com/.Save into new part - There's no feature in the original mb-part. All changes in the original mb-part show up in the new part. In both cases you have to do a convert to sheet metal or insert bends to make sheet metal changes in the new part and to even flatten it. Also in both cases you can break the link with the original mb-part if you need to.

Convert to sheet metal by selecting an edge. Leaving the gap allows it to be converted to sheetmetal. . SOLIDWORKS: Sheet Metal Sketched Bend). This cannot directly make a conic bend though. . makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

solidworks sheet metal pdf

Table of Contents. 1 Getting from 3D Model to Flat Sheet Metal in Sheet Metal Fabrication. 1.0.1 How to locate the Sheet Metal toolbar:; 1.0.2 How to create a sheet metal tab:; 1.0.3 How to unfold your design:; 1.0.4 SOLIDWORKS Tech Tip #3: Unable to Unfold Part, Sheet Metal Bend Radius Issue Solved; 2 8 Design Tips for Making 3D Models That Unfold. 2.1 1. .You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. The imported part must be a constant thickness. If the part you are converting has a formed feature, the formed feature is deleted. You can reapply the feature after the conversion.One of those is sheet metal information. If that's included it should flatten normally. If the sheet metal information is not included you'll have to convert the mirrored part into a sheet metal part using Insert Bends or Convert to Sheet Metal. Mirrored Parts will .

cnc machine vacancy

How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.

Customer designed some "sheet metal" parts but couldn't get a flat pattern. I am trying to re-create the part as sheet metal so I can flatten it for the sheet metal shop. I decided to extruded the base, shell it then convert it and add the flanges I need. My problem is the bends are supposed to be welded and I'm not sure how this should be modeled.In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part.

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part.

Under Sheet Metal Parameters: Select a face as the fixed face for the sheet metal part. Set the sheet thickness and default bend radius. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet Metal feature.In SolidWorks, converting a solid part into a sheet metal part involves several steps. Here's a general guide on how to do this in the video .

cnc machine warm up program

cnc machine validation format

cnc machine wheel repair

$137.00

how to convert part to sheet metal in solidworks|rip solidworks