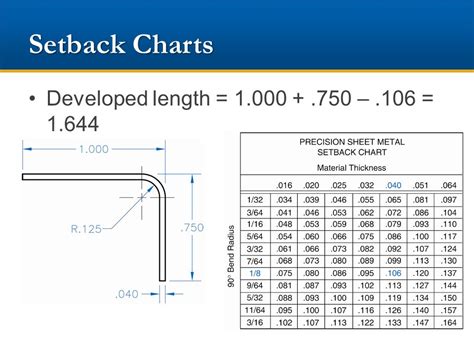

bend allowance table for sheet metal The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness . These sheets and bars are zinc galvanized for good corrosion resistance. Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into parts that .

0 · sheet metal setback chart

1 · sheet metal bending allowance charts

2 · sheet metal bend tolerance chart

3 · sheet metal bend deduction chart

4 · sheet metal bend allowance calculator

5 · bend allowance k factor chart

6 · bend allowance chart pdf

7 · bend allowance calculator sheet

Built with a strong and durable steel frame and a versatile poly jacquard cover that .

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness . By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend .

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. .

Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to . Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent dimensions. This is crucial for creating accurate flat patterns and ensuring that the bent part fits and functions as intended. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances. Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent dimensions. This is crucial for creating accurate flat patterns and ensuring that the bent part fits and functions as intended. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.

sheet metal setback chart

residential cable distribution box

republic sheet metal and manufacturing co. inc

Shop easy to assemble box springs all expertly packed and shipped to your door. Don't forget to pair your box spring with one of our highly rated mattresses for the perfect snooze available in twin, full, queen, king, and cal king sizes.

bend allowance table for sheet metal|bend allowance calculator sheet