cnc concept of machine zero Machine zero is a fundamental concept in CNC machining that establishes the reference point for all operations. This blog post has provided an in-depth exploration of machine zero, its importance, the process of setting it up accurately, common challenges, best practices, and its . A one gang socket simply means it has one plug socket, a two gang socket has two plus sockets on it. Below I have put a photo of a one gang socket and then a two gang socket. One Gang Socket Two gang Socket

0 · machine zero point definition

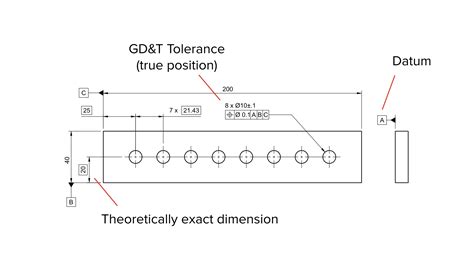

1 · cnc reference hole value

2 · cnc reference hole

3 · cnc machine zero point

Rusty hinges, deteriorating finish, and inconvenient dents can make for a toolbox that's in less-than-ideal shape, and, in many cases, there's not much you can do to fix it back up.

Machine zero is a fundamental concept in CNC machining that establishes the reference point for all operations. This blog post has provided an in-depth exploration of machine zero, its importance, the process of setting it up accurately, common challenges, best practices, and its .The machine zero point refers to the origin of the coordinate system on a CNC .Mastering the art of CNC machine zero point manufacturing involves .In this blog post, we will delve deep into the world of CNC machine zero points, .

The machine zero point refers to the origin of the coordinate system on a CNC machine. It is the point from which the machine determines the positions of all tools and workpieces. Setting the .Mastering the art of CNC machine zero point manufacturing involves understanding the importance of the zero point, employing the most effective techniques for setting it, and . After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool. By understanding and precisely setting Part Zero, operators ensure that the CNC router operates at its best, transforming digital designs into flawless real-world components. Here are seven ways to determine and .

The ability of a control system to return a cutting tool from any position to the machine reference position is a critical feature of all modern CNC systems. Programmers and operators . In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining. For CNC purposes, this origin point is commonly called the program zero point (also called work zero, part zero, or program origin). Typically, the program zero point is chosen as the point where all dimensions begin.

“Zero-Point” really refers to the positional origin of the workpiece, used mainly for programming. Programming utilizing the zero-point of the workpiece is more efficient than using the corner or perimeter when incorporating a center of .In this blog post, we will delve deep into the world of CNC machine zero points, explore their importance, methods of setting them up correctly, and the benefits they bring to the .Machine zero is a fundamental concept in CNC machining that establishes the reference point for all operations. This blog post has provided an in-depth exploration of machine zero, its importance, the process of setting it up accurately, common challenges, best practices, and its impact on precision machining.

The machine zero point refers to the origin of the coordinate system on a CNC machine. It is the point from which the machine determines the positions of all tools and workpieces. Setting the zero point correctly is crucial for accurate machining, reducing .Mastering the art of CNC machine zero point manufacturing involves understanding the importance of the zero point, employing the most effective techniques for setting it, and diligently maintaining calibration. After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool. By understanding and precisely setting Part Zero, operators ensure that the CNC router operates at its best, transforming digital designs into flawless real-world components. Here are seven ways to determine and effectively set the part zero position.

machine zero point definition

The ability of a control system to return a cutting tool from any position to the machine reference position is a critical feature of all modern CNC systems. Programmers and operators understand the term machine reference position as synonymous with . In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining. For CNC purposes, this origin point is commonly called the program zero point (also called work zero, part zero, or program origin). Typically, the program zero point is chosen as the point where all dimensions begin.“Zero-Point” really refers to the positional origin of the workpiece, used mainly for programming. Programming utilizing the zero-point of the workpiece is more efficient than using the corner or perimeter when incorporating a center of rotation, such as in 4 and 5 axis machining applications.

In this blog post, we will delve deep into the world of CNC machine zero points, explore their importance, methods of setting them up correctly, and the benefits they bring to the manufacturing process.

Machine zero is a fundamental concept in CNC machining that establishes the reference point for all operations. This blog post has provided an in-depth exploration of machine zero, its importance, the process of setting it up accurately, common challenges, best practices, and its impact on precision machining.

The machine zero point refers to the origin of the coordinate system on a CNC machine. It is the point from which the machine determines the positions of all tools and workpieces. Setting the zero point correctly is crucial for accurate machining, reducing .Mastering the art of CNC machine zero point manufacturing involves understanding the importance of the zero point, employing the most effective techniques for setting it, and diligently maintaining calibration.

After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool. By understanding and precisely setting Part Zero, operators ensure that the CNC router operates at its best, transforming digital designs into flawless real-world components. Here are seven ways to determine and effectively set the part zero position.

The ability of a control system to return a cutting tool from any position to the machine reference position is a critical feature of all modern CNC systems. Programmers and operators understand the term machine reference position as synonymous with .

In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining.

For CNC purposes, this origin point is commonly called the program zero point (also called work zero, part zero, or program origin). Typically, the program zero point is chosen as the point where all dimensions begin.“Zero-Point” really refers to the positional origin of the workpiece, used mainly for programming. Programming utilizing the zero-point of the workpiece is more efficient than using the corner or perimeter when incorporating a center of rotation, such as in 4 and 5 axis machining applications.

junction box lvzub054

cnc reference hole value

So, with different type of tin available and each containing different combinations of booster packs and accessories, here’s each one in turn, listed from largest to smallest, with details of what we think the advantages and .

cnc concept of machine zero|cnc reference hole