cnc numerical control machine In simple terms, CNC stands for "Computer Numerical Control." This technology enables machines to operate with a high degree of precision and automation by following pre . $4,995.00

0 · who invented cnc machine

1 · what is a cnc mill

2 · numerically controlled machine tool

3 · computerized numerical control cnc

4 · computer numerically controlled machine tools

5 · computer numerical control today

6 · computer numerical control cnc programmer

7 · cnc machine full form

Usinagem em torno CNC de peças em Aço Inox, Latão, Aços Ligados, mediantedesenho ou amostra. Traga seu projeto!

CNC movements are based on the X, Y and Z axes. The tool is positioned using stepper or servo motors, which act on the movements based on the code obtained from the original 3D model of the part you want to create – called the G-code. Numerical controls describe how fast to move the spindle (the . See moreBefore CNC existed, there was only NC. This means Numerical Control (without the “C” of Computer), where back in the 1950s punched tape was used to manually input commands on to data cards to describe where to move the machine and tools to cut parts. This was . See moreWithin CNC there are two main file formats that affect the CNC machining process. Most people have heard of G-code, which are used in both . See moreIn simple terms, CNC stands for "Computer Numerical Control." This technology enables machines to operate with a high degree of precision and automation by following pre .

who invented cnc machine

what is a cnc mill

Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce .What is computer numerical control (CNC)? Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is .

A CNC machine is a more advanced version of an NC machine, which can be controlled via computer software (hence why it is called computer numerical control). While NC tools can still serve a purpose, they require more .

3. Introduction • CNC (Computer Numerical Control) is the name received to machines that are able to position a tool without human assistance • To position the tool, CNC machines have an interpreter that translate a series of instructions (G-Code) to electronic orders (for example, step and direction signals)

The CNC (Computer Numerical Control) machine market has witnessed significant growth in recent years. This market revolves around the use of computerized systems to control machine tools and automate manufacturing processes. CNC machines offer higher precision, accuracy, and productivity compared to conventional manual machines. .Computerized Numerical Control machine: This is the core concept where computers are used to control machine tools. Numerical Control System: Refers to the system that converts designs produced by Computer-Aided Design (CAD) software into numbers, which the CNC system can understand to control the movement of the machine. CNC Machine Automation . What Is Computer Numerical Control (CNC)? Computer numerical control (CNC) is a technology that uses computers to control machines in manufacturing processes. With CNC, computers accurately guide the movements of tools and machinery. The machine follows instructions like a person might follow a recipe.

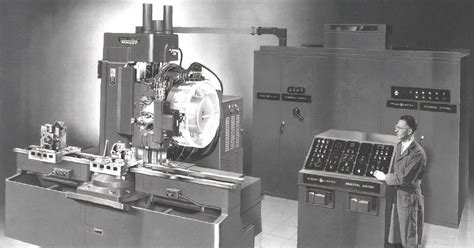

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the .

explanation training and education of lathe and milling machines CNC machining CNC milling machine CNC tuningcnc programming for mechanical engineering basic.CNC system architectures. A computer numerical control (CNC) system consists of three basic components: CNC software that is a program of instructions, a machine control unit, and processing equipment, also called machine tool. The general relationship among these three components is illustrated in Fig. 4.12. (a) CNC software. Both the controller and the computer . The Machine Control Unit is a small computer fitted into the CNC machine. It has two subparts: the Control Loop Unit (CLU) and the Data Processing Unit (DPU). The DPU of the machine control unit handles the movement, software translation, and calculations. The CLU collects the feedback data and forwards it to the machine control unit for .Dublin, Oct. 04, 2024 (GLOBE NEWSWIRE) -- The "Computer Numerical Control (CNC) Machines - A Global Market Overview" report has been added to ResearchAndMarkets.com's offering. The global market .

Numerical Control (NC) A machine tool is operated by a series of coded instructions that include numbers, letters of the alphabet, and symbols that the machine control unit (MCU) can read. These instructions are converted into electrical pulses that the machine’s motors and controls follow to perform manufacturing tasks on a workpiece.While a CNC (Computer Numerical Control) machine can perform certain cutting operations, it cannot completely replace a table saw. Here are some points to consider: 1. Cutting Capabilities: A table saw is specifically designed for straight-line cuts, crosscuts, and rip cuts on various materials, including wood, plastic, and sometimes even metal . CNC MACHINES. Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • CAD (Computer .

numerically controlled machine tool

4. A Definition of NC • Numerical Control is a system in which actions are controlled by the direct insertion of numerical data at some point. • In other words, Programmable automation in which the mechanical actions of a .

A CNC (Computer Numerical Control) machine is essentially a computer-controlled tool designed to produce highly precise and consistent parts. It operates like a sophisticated robot, capable of automatically performing cuts, . The CNC mother machine is the name of a large CNC milling machine designed to produce other smaller machine tools. The CNC mother machine was designed according . Static and dynamic analysis of computer numerical control (CNC) mother machine structure Arif Krisbudiman; Arif Krisbudiman a) 1.

A CNC Machine (Computer Numerical Control) is an electro-mechanical device that uses computer programming inputs to operate machine shop tools. CNC machining is one common way to create prototypes (the other method being 3D printing).

CNC.ppt - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. CNC (computer numerical control) machines are automated machines that are controlled by computer programs to precisely machine parts. There are various types of CNC machines that can perform operations like milling, turning, cutting, and drilling. CNC machining is a manufacturing process in which a computer directs machines using programming codes to make a product. CNC (Computer Numerical Control) machining is a subtractive manufacturing process. This means that the computer program directs these tools (for example, drills, mills, and lathes) to constantly chip away at a workpiece.CNC (Computer Numerical Control) systems are the unsung heroes of manufacturing. They are the driving force behind precision, automation, and consistency. . Understanding the functions of control devices in CNC machine tools is essential for optimizing machine operations and ensuring precision in various tasks. Key Takeaway: Control devices . What is Computer Numerical Control (CNC) Technology? Computer Numerical Control, commonly written as CNC, is a type of control system that can provide automated movement and working of the machine tool. The instructions in CNC technology are written in a .

CNC machines, or Computer Numerical Control machines, offer a range of advanced features that revolutionize manufacturing processes. These machines excel in precision, automation, and versatility, allowing for complex part production with minimal human intervention. Key features include multi-axis capabilities, enabling intricate 3D cuts and .MACHINE SHOP/CNC Los Angeles Pierce College (LAPC) offers the following programs in Numerical Control Programming: . Certificate of Achievement in Numerical Control Programming. The program consists of courses in manual machining (IND TEK 130, 230, 330, 332); CNC (IND TEK 140, 244, 248, 444, 448); CAM (IND TEK 346); and GD&T (IND TEK 105). CNC, which stands for Computer Numerical Control, is a revolutionary technology that has transformed the way machine tools operate. In this guide, we will delve into the meaning, abbreviation, and definition of CNC, as well as explore its significance in various industries.With the introduction of computer numerical control (CNC) technology, woodworking machinery became even more precise and versatile. . CNC machines have become vital in modern woodworking operations, offering unparalleled accuracy and productivity. Today, CMC machinery continues to evolve with cutting-edge technologies such as 3D printing and .

Auto Body Sheet Metal Welding With Different Welders. Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here.

cnc numerical control machine|what is a cnc mill