sheet metal design for welding During the design phase, sheet metal design guidelines focus on the following 5 parameters. Material Selection. During the process, the material characteristics play an important role in determining the suitable process for the specific material. Consider the example of Aluminum and Steel to understand this better. . Mistake 8: Designing .

In this series of Videos Vinny will teach you not just the same Basic rehash that you've seen again and again, but how to understand the basic concepts and planning, that go into every project in.

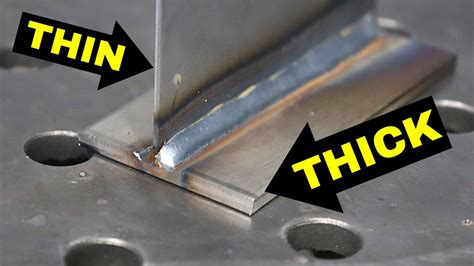

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

$14.99

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and characteristics.Have you ever wondered what type of welding is best for your precision sheet . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Search Now. . Welding Head Access: The design must .What factors should be considered for sheet metal welding design? When designing for sheet metal welding, factors to consider include joint type and geometry, material thickness and type, welding technique selection, accessibility for welding, and the desired strength and aesthetics of the welded joint. Consulting with experienced welders or .

Fixture design for laser welding; Tube part design; Fixture design for arc welding; United States | EN. Contact . cheaper, or more functional: How would you like your parts? When sheet metal parts have a well-thought-out design, this allows your machines for laser cutting, punching, or bending to reach their full potential – while saving on . During the design phase, sheet metal design guidelines focus on the following 5 parameters. Material Selection. During the process, the material characteristics play an important role in determining the suitable process for the specific material. Consider the example of Aluminum and Steel to understand this better. . Mistake 8: Designing .Consolidated Machine and Welding in conjunction with CK Power is looking for a Sheet Metal Design Engineer at our Hannibal, MO facility. The Sheet Metal Design Engineer will work directly with customers and suppliers to confirm compliance with manufacturer guidelines and make suggested improvements.Continuing in our series on Design for Manufacturing, this time we’re taking a look at sheet metal design.As the name implies, this involves designing components and assemblies using formed sheets of thin metal. Sheet metal is my favourite construction material as a designer, and I like to think of it as engineering origami.

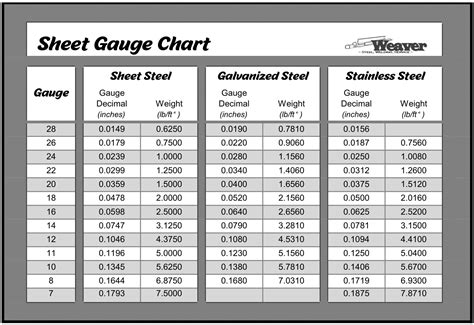

Sheet Metal and Welding Quiz. What happens to the thickness of sheet metal as you go from 8 gauge to 22 gauge? Identify 2 methods of showing sheet metal parts on a mechanical drawing. Identify 2 methods of dimensioning features on a sheet metal part. Define bend allowance and identify 3 factors that impact the amount of bend allowance presence.Our sheet metal design for manufacturing eBook is an essential guide for anyone looking to design parts that can be manufactured faster with less back and forth. . of best practices in sheet metal design of features and common design elements, including hems, offset, notches & tabs, welding, corners, uniform thickness, and more. If you're a .

welding thin to thick metal

- 4 - Forming Near Holes – When a bend is made too close to a hole, the hole may become deformed. Figure "A" shows a hole that has become teardrop shaped because of this problem. To save the cost of punching or drilling in a secondary operation the following formulas can be Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. . Sheet Metal Design Guidelines: Optimizing for Manufacturability. Nov 8, 2024. Sheet Metal Design Guidelines ensure efficient production. Therefore, sheet metal welding is an important aspect of metal fabrication. There are different sheet metal welding techniques, but do you know which is best for your industrial applications? This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications. How to design bend reliefs in SolidWorks. In SolidWorks you have a few different places you can include bend relief. The first is in the initial Sheet-Metal feature that is created when your part is made using the sheet metal tools (or converted to sheet metal). From here you can select to have relief added automatically on bends that require it.

Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge . 20 Welding, Riveting, and Assemblies 21 Resources at Xometry Table of .Sheet Metal Welding Guide • Third Edition iii FOREWORD Sheet metal contractors know that joining metal is a very labor−intense part of their business. Many hours are spent welding the various parts together that make up the total sheet metal system. Managing the welding operation of the contractors business is a vital part of the total .

KSM Industries has full sheet metal welding capabilities including MIG, TIG, Flux Core and Pulse arc welding on mild steel, stainless steels, and aluminum. . Services. Custom Metal Fabrication; Fabricated Enclosures and Sheet Metal . 2 7 Things to Know About Spot Welding 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Spot Welding FAQ. 4.0.1 What is the difference between spot welding and seam welding, and when . 3.0.3 What problems can arise when welding sheet metal parts? 3.0.4 How can interlocking tabs help solve welding-related issues? . Why You Need to Bring Your Manufacturer In During Part Design. Precision sheet metal .

In the original design, the sheet metal required two separate bending processes. However, in the improved design, the sheet metal only needs one bending process to form the two sides at the same time. It is important to keep in mind that the more complex the bending process for the sheet metal, the higher the amount of material waste that may . In sheet metal welding, this surface appears to be the simplest and easiest to work with because of the flat position. The welding is performed from the upper surface and the molten floe is assisted by gravity. . Sheet Metal Design Guidelines ensure efficient production. read more. A Complete Guide To Aluminum Stamping Process. Oct 12, 2024.High-quality sheet metal welding services are provided by Dynamic Design & Manufacturing, with a focus on MIG and TIG welding. Give us a call right now to learn more! Go to Navigation Go to Content. . Sheet Metal Welding Services. Dynamic Design and Manufacturing, Inc., provides precision and sheet metal welding services as part of our full .

The accuracy of surface finish and texturing details in sheet metal design is typically measured and specified during the drawing stage using various parameters and standards. This process is crucial for ensuring the functionality, aesthetics, and durability of the final product. . AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code: This .Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . MIG welding and TIG welding are ideal when dealing with sheet metal, although other processes also work .

welding 14 gauge sheet metal

Additionally, it also can apply welding, riveting, and adhesive bonding to securely join the sheet metal components, ensuring the stability and safety of the vehicle’s structure. Custom Sheet Metal Fabrication Services at Runsom. Runsom Precision offers custom sheet metal fabrication services to meet a variety of design and manufacturing .

As per the survey by American automotive weld quality of the sheet metal assembly process, around 73 percent of the variance problems from pre-production to production were due to fixture based problems. This exertion introduces a new technique of fixture design for the process of sheet metal spot welding.

Manufacturers often have to fit several parts to make a whole during fabrication. Sheet metal welding is a crucial manufacturing process that helps join and assemble metal structures. However, it’s a relatively complex process that requires technical skill to ensure your fabrication meets industrial standards. This article introduces you to welding sheet metal, . 2 Approved Sheet Metal’s Proven Approach to Corner Construction; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Metal Fabrication Corner Construction FAQ. 4.0.1 Why is proper corner construction crucial in sheet metal fabrications? 4.0.2 How does Approved Sheet Metal ensure high-quality corners in every fabrication? 1 Welding vs. Fastening for Sheet Metal Fabrication 1.0.1 Use case #1: Designing a sheet metal fabrication quickly and easily. 1.0.2 Use case #2: Adding strength and durability to a sheet metal fabrication. 1.0.3 Use case #3: Taking apart and reattaching assemblies. 1.0.4 Use case #4: Making a sheet metal fabrication watertight.

welder settings for sheet metal

welded sheet metal manufacturing

$25.00

sheet metal design for welding|welding thin to thick metal