high speed machining cnc Minimizing Chatter via Spindle Speed and Other Tricks. Most machinist’s first . In order to install an electrical outlet and circuit from scratch you need a roll of 14-2 or 12-2 Romex® cable (depending on how much load you need from the outlet) and either a .

0 · high speed milling stainless steel

1 · high speed milling machine manufacturers

2 · high speed machining techniques

3 · high speed cnc drilling machine

4 · high precision cnc milling machine

5 · haas high speed machining parameter

6 · haas high speed machining option

7 · haas high speed machining code

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

high speed milling stainless steel

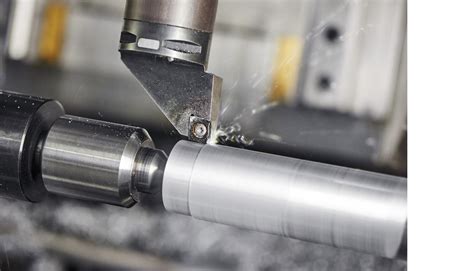

High speed machining (HSM)–also called trochoidal milling, adaptive clearing, volumill, and more–is a milling technique that can increase material removal rates, reduce .Minimizing Chatter via Spindle Speed and Other Tricks. Most machinist’s first .Consider this amazing chart from Dr Herbert Schulz’s, “History of High Speed . How fast can a #CNC machine go? Check it out! High-speed machining (HSM) typically relies on making light #milling passes at a high spindle speed and feed rate to achieve a high metal removal.

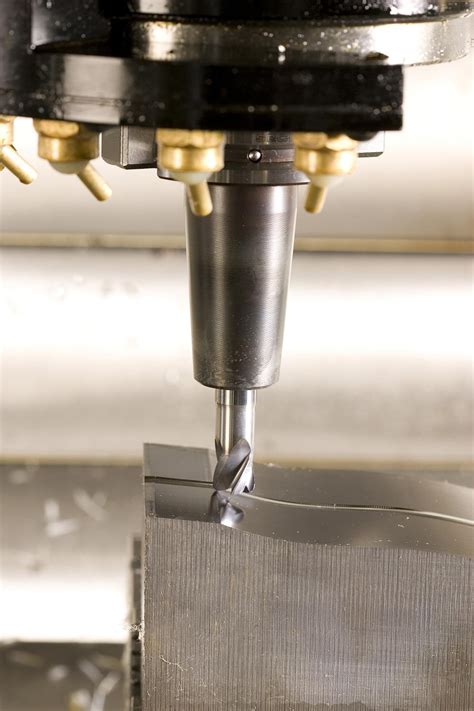

When referring to CNC machine tools, the term high speed machining (HSM) usually means making products or prototypes rapidly by using milling machines at higher spindle rates with lighter, shallower cuts to achieve .High Speed Machining is a machining methodology that focuses on extremely fast but light, low pressure cuts. . I've managed a machine shop with multiaxis CNC machines for aerospace and medical prototyping and contract manufacturing. I also have done a lot of welding/fabrication, along with special processes. Now I run a consulting company to . These requirements include: 1) high speed/high power spindles, 2) proper spindle speed selection based on the system dynamics, 3) machining parameter definition based on tool wear, 4) high feed/high acceleration machine drives, 5) intelligent path generation, and 6) pre-process verification of arbitrary three-dimensional CNC part paths.

High-speed machining was once a niche technology, known only to aerospace shops making large airframe components. No more. High-speed machining (HSM) use is now widespread. So are its counterparts high-feed (HFM) and high-efficiency (HEM) machining. All are now common in shops of all sizes and specialties. That said, shops wishing to pursue a more .Hannover has been focusing on the CNC machine tool industry for 20 years. Its main products include vertical machining centers, high-speed machining centers, inclined bed CNC lathes, flat bed CNC lathes, etc. It can customize special CNC machine tools and product manipulators according to customer needs. This paper introduces a high speed machining algorithm based on a look-ahead interpolation technique for the machining of 3D surface obtained by a CAD/CAM system. Generally, specification of CNC system for high speed machining requires an additional hardware and it burdens end users with additional cost. The purpose of this research is to develop the . Barry uses the Kennametal KOR5 Tool to explain the 8 most important things to consider when High Speed Machining.Help us fund FREE Education by purchasing to.

CNC Working High Speed Milling - iMachining Cutting Metal - CNC Machine ProcessSolidCAM - CHICK OneLOK 1550 - brother speedio 450SolidCAM iMachining: https:/. The recent advances in machining technology are the practice of high-speed machining (HSM). HSM is a metal cutting process that emphasizes rapid speed and feed rates to enhance productivity and surface quality. . It can simulate all types of CNC machine tools and can be utilized for training program without using real machine tools and costly .The high-speed, high precision KENT USA® KVP Vertical Machining Center integrates proven machine design with cutting-edge control and manufacturing technology. Renowned for their reliability and stability, these machines are a top choice for demanding job shops and in-house production facilities.

Excerpts from CNC Machining, a Haas Automation publication. Issue 34, Winter. "Dear Applications: . We are investigating the purchase of a Haas VMC with the High-Speed Machining option. Are special G codes needed for HSM, i.e., G05, G06, G06.1 as used in a GE control for NURBS interpolation? HSM hardware is typically faster, i.e., speeds .High Speed Engineering offers a comprehensive range of Engineering Services including Research and Development, Design, Laser Scanning, 3D Printing, CNC Milling, CNC Turning, CNC Wirecutting, Spark Eroding, Welding, Fabrication, Plasma Cutting, Punch and Die Sharpening, Gear Hobbing, Isotropic Polishing and more all under one roof.

Here is the way I have always done it on our Fanuc's (both an 18i & 30i)..Basically you want to turn your high speed on before you call your tool offset & you want to turn it off after you cancel your tool offset..otherwise toolchange problems are likely to occur. Example: N1 T1 M6 G0 G90 G54 G17 X-10. Y8. S700 M3 G5.1 Q1 (HIGH SPEED ON .

The recent advances in machining technology are the practice of High-speed machining (HSM). HSM is a metal cutting process that emphasizes rapid speed and feed rates to enhance productivity and .

High-speed machining, specifically milling, has the same variables as traditional milling. There are speeds and feeds to set and a depth of cut to be determined. However, in a high-speed machining operation, slow, heavy cuts are replaced .

High Speed Routing, LLC specializes in fast, high quality CNC routing & CNC drilling of plastic, paper and soft metal products to match all fabrication needs. Toggle navigation. Home; . Specializing in the machining of flat stock plastic, .The high-speed CNC machining center tool is the tool material of a high-speed CNC machining center, not the type of tool. It centers commonly utilize materials such as polycrystalline diamonds, cubic boron nitride, and hard coating tools.The Hurco VMXHSi high speed machining centers are equipped with the necessary components for speed, accuracy, and repeatability. The VMXHSi includes ABEC-7 ceramic hybrid bearings and an 18k base speed spindle, which gives you the speed you need and manages the thermal issues associated with high speed machining. The air over oil spindle . I used to "high speed machine" steel up to 60 Rc.. This was P-20, H-13, D-2, M-2, and M-6 mostly. The secret is low depth of cut, high feed rates. High Rpm's isn't exactly high RPM's as you would think. Use normal SFM out of the book or maybe a little higher.

Equipped with Fanuc 0i-MF Control featuring a 10.4″ color LCD and Manual Guide i, the New-Style Horizontal Machining Center boasts a 15,000 RPM built-in spindle with air/oil mist lubrication and cooler, Big Plus CAT-40, 60-tool arm-type ATC, full B-axis with 0.001-degree precision, 2-pallet APC, preparation for field tool setter installation, 400 psi CTS, and an integrated dual .

high speed milling machine manufacturers

High-Speed Machining for Haas Mills. Check out this quick overview of the High-Speed Machining (HSM) option that's available for all Haas VMC and HMC models. HSM lets your mill cut at maximum feed rate where possible, while slowing just enough where necessary, to make sure complex part geometry is maintained.Haas DC Series drill centers that combine high-speed capabilities and space-saving footprints to create versatile vertical machining centers suitable for producing high-precision 2D and 3D parts, such as those found in the communications, aerospace, medical, and automotive industries.

Optimize 3D CNC machining with SolidCAM's HSR/HSM module. Advanced high-speed strategies ensure smooth toolpaths, extended tool life, exceptional surface finish. . High Speed Machining is a must in today‘s machine shops to handle demands for ever-shorter lead and production times, lower costs and improved quality;First there was the giant sucking sound of most of the high-volume machining business rushing offshore. Second there was the post-911 recession that took building vacancies in the valley from only 1,000,000 sq ft to nearly 100,000,000 sq ft in less than a year. . CA’s High Speed CNC, Inc.—a job shop specializing in producing highly . High-speed machining can also create new challenges for machine shops, which must factor material selection, spindle power, acceptable workpiece geometries, available shop floor space, parts complexity, CNC machines (you want those rated for high-speed operations) and operator training into their successful operations.It also sheds light on some of the strategies used in high-speed machining, the physics involved, required CNC machine dynamics and the available technology. Additionally, specific examples are included that provide tooling types along with the feeds and speeds used to achieve exceptional results.

(HC-548EX) Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II – A “NANO CNC System” with Intelligent Velocity Control, NANO Interpolation, and NANO Smoothing Super PC III Function (3-Mode Operation) “Machining Condition Selection,” which allows a range of 1-3 for speed/accuracy settings

how to service a cnc machine

The National Electrical Code (NEC) includes many specific requirements for installation of outdoor circuits and equipment. With outdoor wiring, the primary safety concerns involve shielding against moisture and corrosion, preventing physical damage, and managing issues related to underground burial.

high speed machining cnc|haas high speed machining option