how to make cnc machine step by step pdf How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as . A sheet metal worker specializes in working with thin metal sheets to fabricate, install, and maintain various products and systems. They use blueprints and technical drawings to measure, cut, shape, and join metal sheets using methods like welding, soldering, or riveting.

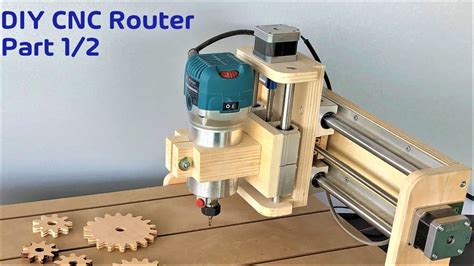

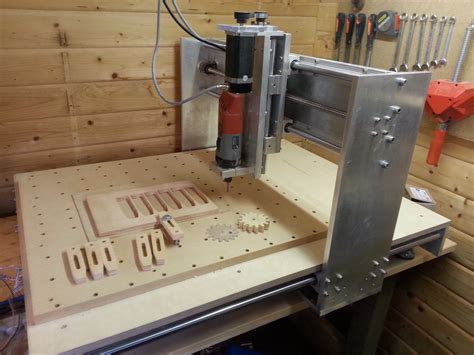

0 · homemade cnc router machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · building your own cnc router

4 · building my own cnc machine

5 · build your own cnc mill

6 · build your own cnc machine

7 · build your own cnc

The options available for potential welding and fabrication businesses are many, so we have chosen the top 10 ideas for starting a successful business to make a profit.

homemade cnc router machine

The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different .This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. You can use it as a drilling machine, a router, a saw, a mill, and even as a lathe.

homemade cnc machine plans

Step-by-Step Guide to Downloading and Using CNC Machine Plans\ To help you get started, we've prepared a step-by-step guide on how to download and use CNC machine plans. Follow .

How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as .

With this page, we’re going to bring together links to articles that cover all the basics you’ll need to use a CNC machine or to get started with the planning to buy or make a CNC machine. If you go through these articles, .

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

Getting Started. Now that you’re aware of the factors to consider let’s dive into the steps to create your CNC machine: Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or .End mill anatomy and tip shapes explained. Cutting techniques for improved eficiency. A deep dive into the G-codes used to control router motion. Discover the new Maker possibilities that .

Step 4: Creating and Loading the CNC Program. CAD/CAM Software. Design the Part: Use Computer-Aided Design (CAD) software to create a digital model of the part. Generate G-Code: Use Computer-Aided .

do it yourself cnc machine

Xcarve CNC Machine: How to safely use the Carve CNC machine to make a cut and pocket engrave. . Accepted formats are (.dxf, *.eps, *.ai, *.pdf, *skp and *svg) Step 5: Make Vector. You can also make vectors directly in VCarve with .This document provides step-by-step instructions to build a mini CNC machine using recycled computer parts like old DVD writers. The CNC machine can be used to draw logos and write text. Key components include stepper motors .CNC machines have revolutionized the manufacturing industry with their precision and efficiency. In this beginner's guide, we will explore the world of CNC machines and how to operate them effectively.Whether new to CNC machining or looking to enhance your skills, this guide will provide valuable insights and step-by-step instructions. Here are 9 easy-to-follow steps to operate a CNC milling machine with ease, whether you are a beginner or a professional. CNC Milling Machine Operating Steps. Step 1. Turn back to the reference point. Step 2. Move the machine table to the middle of the machine (press the negative key, otherwise it will overtravel), and place the workpiece on .

The included step-by-step CNC projects are for both practical and decorative items that will allow you to practice various techniques and specific skills in digital wood joinery and 2-1/2 D carving. . The general principles and instructions detailed are applicable to a wide range of software and CNC machine brands, making this must-have .I then used the CNC machine itself to cut out all of the sides and the base. I made a lid with a piece of plexiglas in the middle. . Step 16: CNC Software. To control a CNC router, you need 3 different types of software. A CAD program, to create a drawing. A CAM program to create the toolpaths and output the G-code. And a controller program .Step 6: EMC2 & Google Setchup to G-gode. This is a quick intro on what software to use to make the CNC machine do something. The software used to produce the DXF and g-code works on Windows Linux Or Mac. The Software used to operate the stepper motors is EMC2 which, is a turnkey linux distro with EMC2 CNC application set up and ready to go. .

This CNC machine is powered by using two stepper motors and one servo motor. That is, it acts across the X, Y, and Z axes. Also, all of these motors are activated using the L293D motor drive shield and Arduino UNO board. If we want to draw a character through this CNC machine, its G-code must be obtained. The Inkscape software has been used for .

The circuit diagram used in this project is shown here, start by connecting the motor drivers to the CNC shield. Followed by connecting the enabling pins together, Now connect the stepper motors to the CNC shield, The laser diode has to be connected to the power supply via IRFZ44N Mosfet and a couple of resistors.

This is a digital download containing the files and complete step-by-step directions on how to make this salad set on a wood CNC router machine, including a salad fork and a matching salad spoon. This includes a detailed PDF with all the steps I go through to make the set, including the solid wood inlay. Cautions. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine.There are three stepping motors and one spindle motor on the machine. Therefore, the current of the CNC machine is very large in the process .In this beginner-friendly tutorial, you'll learn how to create your own maze game in Scratch, complete with multiple levels and fun challenges. Follow along .This is the digital download containing the files and directions on how to make this “Shallow Flow Bowl” on a wood CNC router machine. . Included: Detailed step-by-step directions PDF on how to make this bowl. The directions list all required bits and materials. In general, you will need at least a 1/4″ spiral up cut bit, and a 1/4 .

This video shows the beginner how to make an easy CNC router project from scratch using any CNC router design software. It also lets the beginner know they d.This is the digital download containing the files and directions on how to make this “Shallow Flow Bowl” on a wood CNC router machine. . Included: Detailed step-by-step directions PDF on how to make this bowl. The directions list all .

Deliverable: Hand Written G-Code Part Program. Drilldown on the link to see our Free Tutorial on Hand Writing G-Code Programs. One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual .In this comprehensive guide, we will explore the step-by-step process of creating a CNC router machine from scratch. Get ready to embark on an exciting journey of craftsmanship and innovation! 1. Understanding CNC Router Machine Basics: What is a CNC router machine? Components of a CNC router machine . Different types of CNC router machines Big Picture: Step-By-Step Guide to Making CNC Parts. There are 9 steps to make a CNC part described below. Click on the title of any to drill down and see details for each step. 1. . Tooling consists of the mechanical things we use with our CNC Machine to make parts. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood. . Parts List CNC - Timber.pdf File size: 112.5 KB Views: 2,248. Parts list. Qty Part Name Part Link Comments ; 1 .

60 amp electrical panel box

Mini CNC Milling Machine: Hi friends! In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic. . Step 29: CNC Control Software. To connect my computer to the printer .

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.set expectations so high that you never take the first step. It’s relatively easy to achieve a goal of making 00 and, like that CNC machine cranking out parts, if you can do ,000, you can do ,000 or more. . Many users have accidentally ended up making money with their CNC machines. They make something that they want and show it to .

Building a CNC machine allows you to create your own amazing products. So, . Step 1: Design Your CNC Machine. Image Credits: buildyourcnc.com. When building your own machine, you must create a design for it. Basically, this step is intended to provide a clear structural idea of the finished product.

building your own cnc router

DIY Arduino CNC Drawing Machine: Hello Guys, In this instructable I'm going to show you how to make an Arduino CNC plotter from old DVD writers. . Templates.pdf. . Step 3: Making the Base. In this step, I'm going to make the base for my CNC plotter. So follow the step carefully. First, apply super glue on one piece of acrylic then attach .In this comprehensive guide, we will walk you through the step-by-step process of leveling a CNC machine, sharing valuable tips and techniques along the way. Whether you are a beginner or an experienced CNC machine operator, mastering the art of leveling will undoubtedly contribute to your success in the field. So, let's get started!

building my own cnc machine

The software then generates G-code, the programming language that directs the CNC machine’s movements. CAM software often includes features for optimizing toolpaths to reduce machining time and improve finish quality. Step 4: Milling or Machining Process. In this step, you physically set up your CNC machine.

build your own cnc mill

Corrugate profile is cost effective and versatile, able to handle a wide range of roofing and wall cladding applications. Corrugate profile can also be bullnose curved. Corrugate is available in Zincalume®, Galvsteel®, COLORSTEEL® Maxam™.

how to make cnc machine step by step pdf|do it yourself cnc machine