part programme of cnc machine G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27. Consider your cabinet's construction and door type—whether overlay or inset doors, face frame, or frameless—before delving into hinge options. This guide delineates the ideal hinge choices for each setup, ensuring .

0 · manual programming cnc

1 · manual cnc programming for beginners

2 · how to write cnc code

3 · cnc programming for beginners pdf

4 · cnc programming examples

5 · cnc machine tool programming

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

$99.00

Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the .G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27.

MANUAL PART PROGRAMMING. To prepare a part program using a manual method, the programmer writes the machining instructions on a special format called part programming manuscript. The programmer first prepares the .Computer Numerical Control (CNC) is a method of automating control of machine tools through the use of software embedded in a microcomputer attached to the tool.With CNC, each object to be manufactured gets a custom computer .

Efficiency is key in any programming task, and 5-axis CNC machine programming is no exception. In this section, we will share best practices and tips to enhance efficiency in programming. From selecting appropriate tooling and fixturing to utilizing cutting strategies and optimizing toolpaths, we will provide practical recommendations to . 4. HISTORY 1955 - US Air Force define a need to develop a machine tool capable of machining complex and close tolerance aircraft parts. 1959 - MIT is the contractor and builds the machine for the project. MIT announces Automatic Programmed Tools (APT) programming language 1960 - Direct Numerical Control (DNC). This eliminates paper tape and allows . Leading CNC machines and manufacturing solutions provider Mazak has been leading the way with its automation tools for part programming. In this article, we explore how Mazak’s automation solutions are changing the way parts are programmed, and how these technologies can be used in small to medium machine shops. 2. Introduction to Computer Aided Manufacturing - CAM Computer Aided Manufacturing involves the use of computer programs specifically designed to create the geometry and tool paths needed for parts to be machined. These tool paths can then be automatically processed into a program specific for the CNC machine to be used.

Deliverable: Hand Written G-Code Part Program. Drilldown on the link to see our Free Tutorial on Hand Writing G-Code Programs. One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual Machine. If you already know manual machining on a mill or lathe, you can be doing exactly the same kinds of things quickly on a CNC too.

CNC (Computer Numerical Control) part programming involves creating a set of instructions that guide a CNC machine to perform specific operations on a workpiece. These instructions, often written .

CNC Part Programming for Milling Component.Name of Faculty- Vivek SurveM.E- Advanced Manufacturing Systems Storage of more than one part program - CNC machine can store multiple programs. It can be used again and again. 2. Various forms of program input - Multiple data entry capabilities such as magnetic tape, floppy discs, manual data input, communication ports, etc. 3. Program editing at the machine tool - Helps in testing and correcting a program .The earliest NC machines performed limited functions and movements controlled by punched tape or punch cards. As the technology evolved, the machines were equiped with increasingly powerful microprocessors (computers) with the addition of these computers, NC machines become CNC machines. CNC machines have far more capability than their predecessor. For more complex parts, however, some shops choose to use CAM (computer-aided manufacturing) software to program cutting toolpaths and generate G-code that controls CNC machines operations. In fact, you’ll find that many shops have dedicated CAM departments. The decision on whether to use CAM software or not is usually driven by part complexity.

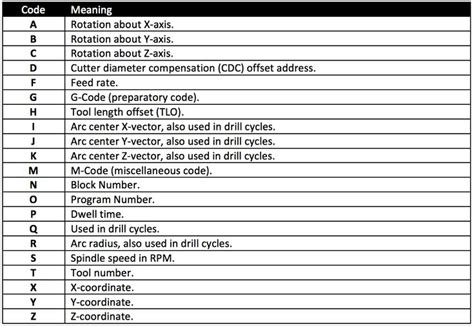

The component of the CNC machine that reads and executes a part program is called: The machine control unit. Which statement about the demands of modern manufacturing is true? T-codes: These codes help machines understand what type of tool is needed for specific areas of a part. Writing Your Own CNC Code. . Below is an image of a 3-axis CNC machine, which is one example of a tool that uses . This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of .As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically a detailed step-by-step procedure that gives the necessary instructions to the various parts of a CNC machine tool, to produce the part. Thus, the actual utilization of the .

A Comparative Study of CNC Part Programming Addressing Energy Consumption and Productivity . To generate a NC part program in the machine controller, the authors looked for the easiest way, as technicians normally do. Nested cycles with sub-routines that include the M97 code were used. The most complex geometry was the surface N with an .Study with Quizlet and memorize flashcards containing terms like What part of a CNC system reads and executes the machining instructions in the part program?, What is the purpose of a CNC machining center? Machining centers enable a single machine to:, Which of the following is an advantage of CNC systems? CNC systems: and more. 1.3 Theory of CNC Milling Machine 1.3.1 Characteristics of CNC Milling Machine Tools Work part machining on CNC machine tools requires controllable and adjustable infeed axes which are run by . or a real value (e.g. X+60 : Approaching the target coordinate X=60). Example of part program: N110 F95 S850 M03 N115 G00 X+ 25 Y+30 .

11. • By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining. • All CNC machining begins with a part program, which is a sequential instructions or coded . Computer Numerical Controlled (CNC) machine programming: . Produces quality parts within a short period of time. Anything can be created by using comprehensive electronics and PCB design tools. Fusion 360 with Power Mill. Provides expert CNC programming for complex 3 and 5-axis manufacturing. Nc part programming - Download as a PDF or view online for free . The manuscript is a listing of the positions of the tool relative to the workpiece that the machine must follow in order to perform the processing. The listing may also include other commands such as speeds, feeds, tooling, and so on. A punched tape is then prepared directly .

3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component .CNC | CNC part program, CNC programming | Introduction of part program | G code | M code #lecture 2In this video you will learn about part program which is u.

manual programming cnc

manual cnc programming for beginners

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a .

The order of the part program is 1. Preparatory function, 2.Feed function, 3.Tool function, 4.End of block. 26. What is meant by manual part programming? Manual part programming is a process of writing programs which consist of a set of instructions to carry out the machining of the work. 27. Write the disadvantages of manual part programming.

how to write cnc code

cnc programming for beginners pdf

cnc programming examples

$9.99

part programme of cnc machine|manual programming cnc