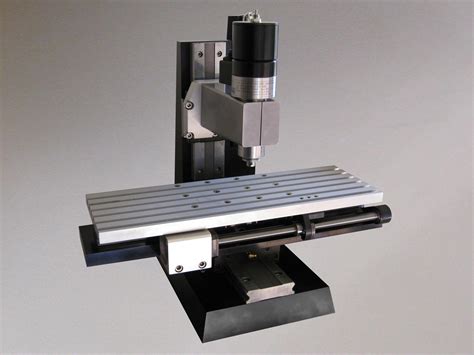

diy cnc milling machine This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

"Keep your workshop or garage organized with a Stack-On, two-shelf wall cabinet. This welded steel cabinet comes mostly assembled. The door handles can be mounted in minutes. Cabinet has two fixed shelves that can hold up to 65 lbs. each. Doors close with double enforced powerful magnetic strip that holds the cabinet door securely closed.

0 · make your own cnc mill

1 · machine to make your own

2 · home built cnc milling machine

3 · do it yourself cnc machine

4 · diy cnc mill kit cost

5 · cnc ready to run projects

6 · build your own milling machine

7 · build your own cnc mill

It is imperative you consider the shielding gas, welding process, and electrode before welding 20-gauge sheet metals. In the US sheet metal is designated through the gauge, the larger the number the thinner the metal. Typically, the gauges run from 7 to 30 gauge.

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal .

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill .

In this chapter, we will guide you through designing and fabricating a sturdy and precise frame for your DIY CNC milling machine. We will cover essential considerations such as rigidity, .

In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill .A DIY CNC milling machine may be just what you need. With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In .This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow .

Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get.In this chapter, we will guide you through designing and fabricating a sturdy and precise frame for your DIY CNC milling machine. We will cover essential considerations such as rigidity, stability, and vibration damping, ensuring optimal performance.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.

A DIY CNC milling machine may be just what you need. With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In this guide, we'll walk you through the process of building your own CNC milling machine from scratch.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.

2 metal balls in a box

Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing? AMAZING! DIY CNC Milling Machine - Homemade Machine Cutting Multi MaterialReference documents: https://drive.google.com/drive/folders/1DaekM507D3JfVYbGtjfVHP.

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get.

2 insulated metal roofing sheets suppliers

In this chapter, we will guide you through designing and fabricating a sturdy and precise frame for your DIY CNC milling machine. We will cover essential considerations such as rigidity, stability, and vibration damping, ensuring optimal performance.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic.A DIY CNC milling machine may be just what you need. With the right tools, materials, and know-how, anyone can build a custom CNC mill that can cut metal with precision and efficiency. In this guide, we'll walk you through the process of building your own CNC milling machine from scratch.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin. Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?

make your own cnc mill

machine to make your own

2 section basket fabric metal

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

diy cnc milling machine|do it yourself cnc machine