can cnc machine sumps sit directly on the concrete floor yes, follow manufacturer's specs, or equivalent. If there's good ground under the slab it should be ok. also, i like to make plates, and mount the plates to the floor BEFORE the machine is placed, using the machine layout diagrams. Then I make some 'hockey pucks' for . Walters Sheet Metal, Inc. is proud to provide an array of air conditioning & heating services across Leesville, LA. Contact our AC & heating contractors today for more information! Call Us Today! (337) 239-4579. Call Us Today! (337) 239-4579. Home; Services. Air Conditioning;

0 · concrete slab thickness cnc machine

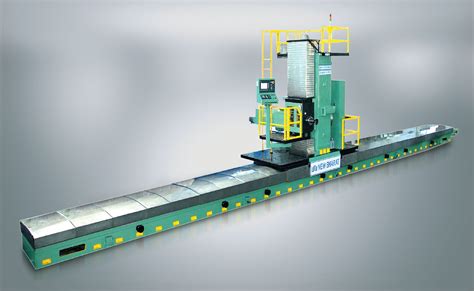

1 · cnc flooring machine

$9.99

concrete slab thickness cnc machine

yes, follow manufacturer's specs, or equivalent. If there's good ground under the slab it should be ok. also, i like to make plates, and mount the plates to the floor BEFORE the machine is placed, using the machine layout diagrams. Then I make some 'hockey pucks' for . Having a contractor chop a hole in the floor and pour two feet on concrete isn't that expensive. The machine will probably be fine if the floor is old, and you anchor it nicely. The .

If a machine is just sitting on the floor, then as the floor shifts, and they all do, the machine will shift. If it is not properly anchored then you take your chances how it shifts. From .

sheet metal norfolk va

I am building a shed for my cnc machine because I need more shop space. Planning to build onto of a current 3" slab of concrete and build simple floor with joist and 3/4 ply on top. Joist will be .For the CNC machines we have I designed concrete pads of appropriate masses and thicknesses that are isolated from the rest of the shop. For example I think I had a 36-40” nominal .The concrete floor is planned to be 4" thick but for only the cost of materials I can make it 6" if that is necessary. I also have the choice between fiber reinforced concrete or the use of re-bar or . yes, follow manufacturer's specs, or equivalent. If there's good ground under the slab it should be ok. also, i like to make plates, and mount the plates to the floor BEFORE the machine is placed, using the machine layout diagrams. Then I make some 'hockey pucks' for the leveling adjustment, then weld it all together when in place.

How big are the pads the machine is sitting on? If the problem continues, set the machine on some 1/2" or 3/4" thick steel plates and epoxy the plates to the floor. This will distriblute the load over a larger area and may help with settling. Having a contractor chop a hole in the floor and pour two feet on concrete isn't that expensive. The machine will probably be fine if the floor is old, and you anchor it nicely. The issue will be the poor little Haas Mini-mill (or any other machine) that's sitting next to it, trying to cut a finish pass when that 60,000lb Okuma is changing pallets.

If a machine is just sitting on the floor, then as the floor shifts, and they all do, the machine will shift. If it is not properly anchored then you take your chances how it shifts. From my experience bolting down is much better and easier to maintain machine geomerty. It also depends on what type of machines you are installing. Some machines only have 3 leveling feet (even some pretty big ones) and do not rely on the floor for additional rigidity or geometric accuracy.

I am building a shed for my cnc machine because I need more shop space. Planning to build onto of a current 3" slab of concrete and build simple floor with joist and 3/4 ply on top. Joist will be directly on the concrete slab. For the CNC machines we have I designed concrete pads of appropriate masses and thicknesses that are isolated from the rest of the shop. For example I think I had a 36-40” nominal thickness pad poured for the VF3, then anchored the machine to the pad. So I am going to get rid of the adjustable feet and make a concrete base/stand. I have seen some steel stands on casters and such, but I want something heavy, rigid and "at one with the floor". Has anyone built such a base?The concrete floor is planned to be 4" thick but for only the cost of materials I can make it 6" if that is necessary. I also have the choice between fiber reinforced concrete or the use of re-bar or road mesh for reinforcement.

a 25K VMC should be fine on 6" or more of concrete. I have 4 29k HMC's running on a 6-8" concrete floor with no special prep. will they be more accurate on a stiffer base - well maybe over time, but 2 of them lasered +/-3 microns in a 20 x 16 x 16 work envelope as they sit. yes, follow manufacturer's specs, or equivalent. If there's good ground under the slab it should be ok. also, i like to make plates, and mount the plates to the floor BEFORE the machine is placed, using the machine layout diagrams. Then I make some 'hockey pucks' for the leveling adjustment, then weld it all together when in place.

How big are the pads the machine is sitting on? If the problem continues, set the machine on some 1/2" or 3/4" thick steel plates and epoxy the plates to the floor. This will distriblute the load over a larger area and may help with settling.

Having a contractor chop a hole in the floor and pour two feet on concrete isn't that expensive. The machine will probably be fine if the floor is old, and you anchor it nicely. The issue will be the poor little Haas Mini-mill (or any other machine) that's sitting next to it, trying to cut a finish pass when that 60,000lb Okuma is changing pallets.

If a machine is just sitting on the floor, then as the floor shifts, and they all do, the machine will shift. If it is not properly anchored then you take your chances how it shifts. From my experience bolting down is much better and easier to maintain machine geomerty. It also depends on what type of machines you are installing. Some machines only have 3 leveling feet (even some pretty big ones) and do not rely on the floor for additional rigidity or geometric accuracy. I am building a shed for my cnc machine because I need more shop space. Planning to build onto of a current 3" slab of concrete and build simple floor with joist and 3/4 ply on top. Joist will be directly on the concrete slab. For the CNC machines we have I designed concrete pads of appropriate masses and thicknesses that are isolated from the rest of the shop. For example I think I had a 36-40” nominal thickness pad poured for the VF3, then anchored the machine to the pad.

So I am going to get rid of the adjustable feet and make a concrete base/stand. I have seen some steel stands on casters and such, but I want something heavy, rigid and "at one with the floor". Has anyone built such a base?The concrete floor is planned to be 4" thick but for only the cost of materials I can make it 6" if that is necessary. I also have the choice between fiber reinforced concrete or the use of re-bar or road mesh for reinforcement.

sheet metal paint processing

Explore a wide range of our Wasp Golgotha selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy returns!

can cnc machine sumps sit directly on the concrete floor|concrete slab thickness cnc machine