electrical box behind light Electrical box installation is regarded as easy work—more like carpentry than electrical wiring. But there are still some common errors that do-it-yourselfers frequently make. Follow these easy tips to make sure your . Sheet Metal teaches you how to build sheet metal parts using SOLIDWORKS mechanical design automation software. Building standalone sheet metal parts, and converting conventional parts to sheet metal, including in assembly context, are covered.

0 · types of metal electrical boxes

1 · standard size electrical boxes

2 · size of electrical outlet box

3 · residential electrical work boxes

4 · residential electrical outlet boxes

5 · plastic electrical outlet boxes types

6 · lowe's electrical outlet boxes

7 · electrical box size chart

Springback is always a difficult problem when bending sheet metal parts. What is it? Why does spring back occur in bending operation? How to reduce? The following is a detailed explanation. 1. What is springback in sheet metal bending? We all know that springback occurs during sheet metal forming.

Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole . Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. . An old work (retrofit) electrical box is a type of electrical box for outlets, light switches, and other devices that is installed after drywall has already been put in place. This allows you to retrofit an existing wall or ceiling without . With the variety of different electrical boxes available at home centers, how do you know what to buy? Don’t worry, it’s not that complicated. We’ll whittle it down to about a dozen boxes to cover almost every situation.

Electrical box installation is regarded as easy work—more like carpentry than electrical wiring. But there are still some common errors that do-it-yourselfers frequently make. Follow these easy tips to make sure your .

Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are .Crafted from durable pre-galvanized steel, these boxes are designed to house wiring devices such as switches or outlets. With RACO's Switch Electrical Boxes, convenience is key. The .

types of metal electrical boxes

Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole in your siding and mount a retrofit light box into the wall cavity.

These boxes allow you to add new electrical devices without affecting your drywall. Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available in both plastic and metal.

Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box. Add an outdoor electrical box to get power to where you need it, especially for holiday lights. Do it safely and easily. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. Lightweight fixtures can hold up on plaster or drywall if you have a remodel electrical box. An old work (retrofit) electrical box is a type of electrical box for outlets, light switches, and other devices that is installed after drywall has already been put in place. This allows you to retrofit an existing wall or ceiling without going through the hassle of removing drywall and plaster.

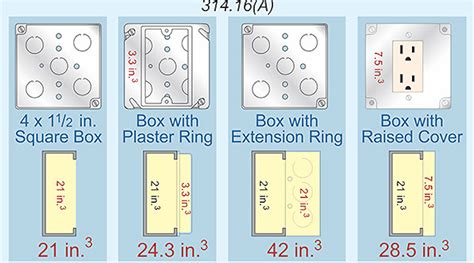

With the variety of different electrical boxes available at home centers, how do you know what to buy? Don’t worry, it’s not that complicated. We’ll whittle it down to about a dozen boxes to cover almost every situation. Electrical box installation is regarded as easy work—more like carpentry than electrical wiring. But there are still some common errors that do-it-yourselfers frequently make. Follow these easy tips to make sure your electrical box installation looks professional and meets code requirements. Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold.Crafted from durable pre-galvanized steel, these boxes are designed to house wiring devices such as switches or outlets. With RACO's Switch Electrical Boxes, convenience is key. The .

Electrical code requires that all junctions be accessible in a box, so you definitely need one here. You have two choices (that I know of at least): cut a large hole in your siding and mount a retrofit light box into the wall cavity. These boxes allow you to add new electrical devices without affecting your drywall. Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available in both plastic and metal. Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box. Add an outdoor electrical box to get power to where you need it, especially for holiday lights. Do it safely and easily.

Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. Lightweight fixtures can hold up on plaster or drywall if you have a remodel electrical box.

An old work (retrofit) electrical box is a type of electrical box for outlets, light switches, and other devices that is installed after drywall has already been put in place. This allows you to retrofit an existing wall or ceiling without going through the hassle of removing drywall and plaster.

With the variety of different electrical boxes available at home centers, how do you know what to buy? Don’t worry, it’s not that complicated. We’ll whittle it down to about a dozen boxes to cover almost every situation. Electrical box installation is regarded as easy work—more like carpentry than electrical wiring. But there are still some common errors that do-it-yourselfers frequently make. Follow these easy tips to make sure your electrical box installation looks professional and meets code requirements. Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold.

satin stainless steel cabinet handles

schematic model of sheet metal process

Metal roofs are made of strong metals, including tin, aluminum, zinc, copper, and steel. They’re more durable than asphalt shingles, so they have longer life spans. Metal roofs can withstand extreme weather, such as heavy snow and radiant summer heat, and winds of .

electrical box behind light|residential electrical outlet boxes