safety in cnc manufacturing In addition to specific safety training for CNC machines, employers are required to provide equipment and training to meet the OSHA standard for noise protection and other personal . See more Whether you want shiny metallic silver fabric or glittery metallic gold fabric, we’ve got all the metallic fabrics you’ll need to make your quilt shine bright. One of the best things about metallic fabric is you can use it for, well, nearly anything you want!

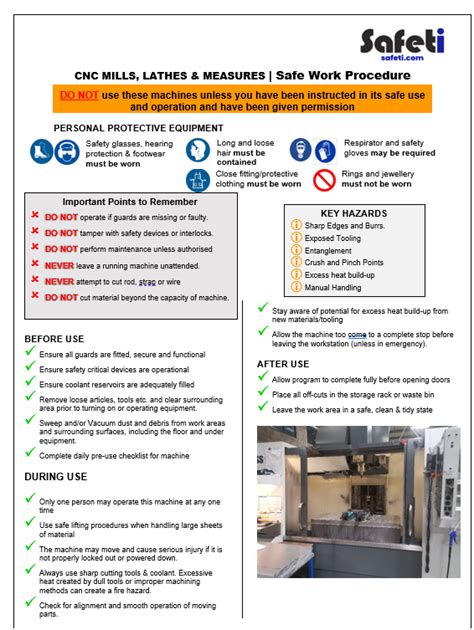

0 · safety glass for cnc machines

1 · osha safety for cnc machining

2 · milling machine safety precautions pdf

3 · milling machine hazards and risks

4 · cnc milling machine safety precautions

5 · cnc machine safety pdf

6 · cnc machine safety checklist

7 · cnc machine safe operating procedure

Nope, you have non grounded cables (two wire), so you don't have a ground. There is no need to cut the grounding wire in the fixture, just wrap it in a ball and place it in the box out of the way of any energized connections. You .

Cutting tools can be very expensive, and operators know that if they use a cheaper tool they can save a little money, Quarato says. But CNC user manuals warn against altering the tooling or working outside the programmatic functions of the machine, he notes, and with good reason. “Alterations of any kind can cause . See moreMost employers know that having a clean machine will not only protect and extend the life of the machine, but also produce higher-quality parts. At the same time, housekeeping and total clean machine policies are mandatory for safe operations of CNC machines, . See moreIn addition to specific safety training for CNC machines, employers are required to provide equipment and training to meet the OSHA standard for noise protection and other personal . See moreAside from the fact that they are powerful enough to cut solid metal, CNC machines are dangerous in the sense that their surfaces can . See more

Discover CNC machine safety, including potential hazards of the CNC machines, their safety features, and guidelines on how to prevent accidents in the workplace. Safety wire holes suck giant monkey balls covered in donkey sweat. How to take a 5 cent nut or bolt and turn it into a 5 dollar nut or bolt. Guy I worked for loved that crap, bushings spacers washers nuts. A lot of safety wire holes, I got to . I was slotting a small block of acetal with a 1/4 extra long carbide end mill. Part slid in the vise a little, then grabbed the end mill and kicked the part out of the vise. Not a big deal to lose 5 dollars of plastic and a 12 dollar end mill, but those tiny . To help you avoid fatalities and ensure a smooth machine operation, here are some vertical machining center safety tips that you must follow to minimize the risk of injury. Ensure proper maintenance and hygiene. .

Manufacturing standards serve as benchmarks, defining the acceptable parameters for quality and safety in CNC machining. Quality testing and inspection play a crucial role in verifying compliance with these standards. By rigorously examining the output of the CNC machining process, manufacturers can ensure that their products meet industry . CNC machining enhances workplace safety by automating production, enclosing dangerous operations, and minimising human contact, significantly lowering the risk of injuries. This automation not only protects workers but also fosters a safer working environment. 6th September 2024. CNC Machining. Rennd; About;Then had to change some other angles because it wouldn't work when installed. For the cammed area and safety detent i used 1/8 and 2mm ball endmills. I also used a bandsaw to remove parts and shape the lever part. I have not test fired the parts yet. If you have a mill or cnc and would like to assist in testing this design, i could use the .

CNC machining significantly enhances safety in manufacturing environments by reducing human interaction with dangerous machinery. With automated processes, operators can oversee multiple machines from a safe distance, minimizing the risk of accidents associated with manual handling and tool changes. These safety features collectively create a secure environment that is imperative for the smooth and safe execution of CNC machining operations. Essential Safety Guidelines for Operating CNC Machines. Safety isn’t just a priority but a mandatory practice that ensures both the well-being of operators and the smooth functioning of the machine. CNC machines have revolutionized manufacturing, enabling an unprecedented level of precision and automation in industries such as automotive, aerospace and general manufacturing. However, as these machines advance in technology and capability, it is also crucial to consider the safety issues surrounding the entire CNC machining process.. In this .

CNC machining has become an integral part of various industries, as it offers precision, efficiency, and versatility when it comes to manufacturing custom parts and components. This manufacturing process has evolved from the numerical control (NC) machining process, which used punched tape cards to control machinery. CNC stands for Computer.In this blog post, we will provide a comprehensive checklist for ensuring safety while operating CNC machines. By following these guidelines, both operators and employers can create a safe working environment and reduce the risk of accidents. . CNC machining is a versatile manufacturing technology that can be used for a wide range of .Essential Safety Measures for CNC Machine Operation . Personnel Training and Competency . Machine Guarding . Regular Maintenance and Inspection . Personal Protective Equipment (PPE) . CNC machining is a versatile manufacturing technology that can be used for a wide range of applications. Common examples include components for the aerospace . CNC machines minimize the need for direct human interaction with dangerous tools and machinery, enhancing safety in the manufacturing environment. . CNC machining plays a vital role in the automotive industry for prototyping, mass production, and customization of parts. CNC machines enable the precise manufacturing of engine components .

safety glass for cnc machines

Introduction. In the realm of manufacturing, CNC (Computer Numerical Control) machines play a pivotal role in automating processes, enhancing precision, and boosting efficiency. However, with the power and complexity of these machines comes a heightened responsibility for ensuring safety in their operation. Neglecting safety protocols can lead to . Learn more about how the Autofacer® increases manufacturing safety. Risk 3: Overriding Door Safety Interlock. Related to Risk 2, a CNC machine’s door safety interlock feature is designed to prevent machinists from . This document gives the safety requirements and measures for numerically controlled (NC/CNC) boring machines, NC/CNC routing machines and NC/CNC combined boring/routing machines (as defined in 3.2 and 3.3), designed for continuous production use,. Citizen A20 dual check safety, safe test over time alarms. Thread starter hodaken; Start date Oct 1, 2021; Replies 7 Views 2,777 H. hodaken Plastic. Joined Jun 21, 2017. Oct 1, 2021 #1 Hey all, . CNC Machining. ABOUT PRACTICAL MACHINIST.

Ensure all personnel who operate or work near CNC machines receive comprehensive safety training. Conduct regular refresher courses to reinforce safe practices and to update employees on any new safety protocols. . CNC machining is a versatile manufacturing technology that can be used for a wide range of applications. Common examples include .

There is no electrical way or a parameter to change for bypassing the safety switch on your Daewoo. The key is there only to enable/disable the lock, disabling it allows you to open the door while your machine is running, but it will cause immediate emergency interveniance , i.o.w. open the door is the same as hitting emergency-or reset button.

As manufacturing processes evolve and new CNC technologies emerge, machinists who stay current with the latest advancements are better equipped to succeed in the industry. Lastly, a strong commitment to safety practices is paramount, as CNC machining involves working with powerful machinery and potentially hazardous materials.Using the right tooling is essential for CNC machine safety and optimal performance. Operators should select the appropriate tools for each machining operation and ensure they are in good condition. . CNC machining is a versatile manufacturing technology that can be used for a wide range of applications. Common examples include components for .

Use safety lines to make absolutely sure your CNC is in the correct mode. Here is an example of a safety line to use at the beginning of a program: O1000 (Start of safety code) G20 G17 G40 (G20 inch, XY plane, cancel cutter compensation) G49 G64 G80 (cancel tool length compensation, normal cutting mode, cancel canned cycles) G90 G94 G98 . I n conclusion, integrating CNC machines and machine safety and machining into modern manufacturing processes necessitates a parallel commitment to safety. The well-being of the workers and the protection of those operating CNC machines and machine safety and equipment are mutually reinforcing objectives. By embracing comprehensive training .

These components often require strict tolerances and high-strength materials, which CNC machining can provide, ensuring safety and performance. 2. Automotive Manufacturing. In the automotive industry, CNC machines are extensively employed to produce engine components, body structures, and interior parts. The high precision and consistency of .

In conclusion, prioritizing safety in CNC machine workshops is not only essential for the well-being of employees but also for the overall success of the manufacturing process. By following the guidelines and implementing the safety measures discussed in this guide, CNC machine operators can create a risk-free environment, reducing accidents .

This online CNC Machinist course will provide you with the knowledge and skills you need to prove competency and begin your career quickly. The course provides an intensive overview of the skills necessary to perform CNC machining, including workholding, math, inspection, safety, metal cutting, materials, quality, and grinding. Learning CNC machining can be challenging at first, but it becomes easier with practice. Several factors determine the complexity of learning CNC machining, including the type of CNC machine, the software used, and the learner’s technical background.. Technical Knowledge: A solid understanding of basic mechanical and electrical principles is beneficial .

1970 ford f100 sheet metal

osha safety for cnc machining

An electrical junction box is a very important part of your electrical wiring system. Without a junction box, you simply cannot have that many different types of electrical outlets , switches, or data hookups in a room.

safety in cnc manufacturing|cnc milling machine safety precautions