what size hole for plug weld sheet metal Testing plug weld hole sizes to see which is best on sheetmetal .more. How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes.

0 · welding symbol for plug weld

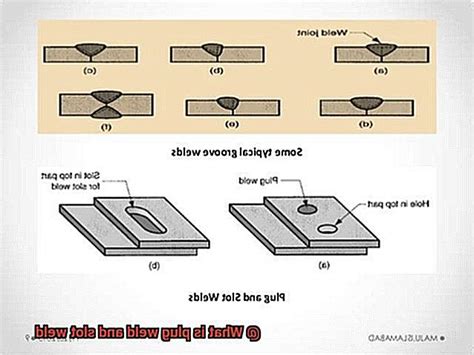

1 · types of plug welds

2 · plug weld vs spot

3 · plug weld vs fillet

4 · plug weld size chart

5 · plug weld not completely filled

6 · plug weld hole size chart

7 · how to plug weld holes

The textbook answer is the MF marked Wagobox must be used with Wago connectors specified in the box’s instructions for the junction to comply with the reg for maintenance free use.

I use 1/4" holes for sheet metal and usually 5/16-3/8 holes for light plate. There actually is a chart that can be found online for structural rosette welds. I have one in one of my . I see the tools avaliable for making holes are 5mm dia. Some people recommended hole size should be 7.5 mm. I notice that some drill through the hole and . Testing plug weld hole sizes to see which is best on sheetmetal .more. Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

A plug weld, or rosette weld, is a welding method that joins overlapping metal sheets by filling pre-cut circular holes with molten metal, creating strong, discreet joints. Widely used in automotive and construction . Plug welding involves joining two overlapping sheets of metal by welding through the top sheet to the bottom sheet, creating a strong and concealed bond. This method is commonly used in automotive and sheet .

Hole Creation: Mark the location for the plug weld and carefully drill a hole of the specified diameter in the first workpiece. The size of the hole should be in accordance with the welding requirements and the thickness of the base .These 14-gauge welding discs are designed to fill the holes left over from shaving body trim, smoothing firewalls, or even that little rust spot in a body panel. This 29-piece kit includes sheet metal patches in several conventional hole sizes. . Plug welds are complete; I used a 5/16 in. hole. Some of the plugs turned out ok; the others didn't turn out quite like I would have hoped. Even with sheet metal screws in place to draw the two pieces of metal tight together, I experienced some separation when I . Get the 2 pieces as close together as possible with clamps, vice grips, sheet metal screws or even dent it if you have to. Cut the mig wire flush with the nozzle every time before you start, I like to start the weld on the frame rail in the centre .

What size plug weld should be used for 1/8" steel? . On car body sheet metal I've used 1/8" holes and they work out very well. Dave J. . Lots of nice holes already stamped out to plug weld at multiple locations. I was just talking to him earlier tonight to fix another truck.this one a 10 year old Suburban 2500 with the rear bumper/frame .Plug welding. Start off by drilling 7.5mm holes in the front sheet of metal at a spacing of normally 25mm to 40mm (or whatever the original spot weld spacing was). Then clamp this sheet onto the back sheet. 7.5mm is a reasonably good hole size for 0.8 or 1.0mm sheet. Thicker sheet might require a slightly larger hole size. Sounds like you are confusing the restriction on the fillet weld size for a lap joint with a plug weld. The minimum diameter of the hole for a plug weld (per D1.1) is the thickness of the part plus 5/16 inch. The strength of the plug weld is based on the area in shear, i.e., the area of the hole at the faying surface. Put it behind the hole and start welding around the periphery of the hole. Weld in a circle and move to the center as you finish up. The back side of the weld will be flat. If the hole you want to weld up is any bigger a good approach is to make a plug of sheet metal the size of the hole. Then just weld the plug into the hole, using tack welds.

As far as the plug weld and hole size, even melt cheese holds the bread together when it cools. But if a guy can't figure out how to get the pan hot it kind of defeats the grilling purpose. Steel Spot And Plug Weld Nugget Size: UPDATE (i-car.com)

welding symbol for plug weld

types of plug welds

Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW. Unlike MIG and TIG, stick welding doesn’t require a shielding gas. . If you blow holes in the metal, you’ve gone further in the wrong direction. Some excessive heat warps the metal sheet, but too much burns it away . 3/16 or 5/16 holes for sheet metal plug welds 11-01-2006, 07:46 PM. Looking at getting an air flange/punch tool and just wondering what sized punch works better for sheetmetal. . one welding truck trailblazer 301g w/ spool/mig/plasma/drill press/ band saw/ and all the other stuff to do this/and air compresser. Comment. Post Cancel. Hotfoot.

What is the consensus for the size of the drill hole in the sheet metal when preparing for a plug weld. I have seen posts of 1/4 and others say 3/16 and I have seen others. This is for the upper/lower cowl and battery apron replacement. Also what is the proper spacing for the plug welds across the cowl.

Hi Chris, Sorry a bit late to your show. check out this video from a high-end e-type coach builder guy. He attaches panels with sheet metal screws and then fills the small 1/8" hole followed by the 1/4" flange hole to make a strong plug weld. Monocoque Metalworks Around the 1:30 mark or so. Comprehensive 29-Piece Kit: The kit includes a total of 29 sheet metal patches in multiple conventional hole sizes, ensuring you have the right size for your specific hole-filling needs. Strong and Durable Construction: Made from 14-gauge steel (approximately 0.0747" or 5/64" thickness), these welding discs offer robustness and durability to . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

Plug weld kit: https://www.eastwood.com/eastwood-sheet-metal-plug-kit.html?utm_source=youtube&utm_medium=annotation+&utm_campaign=2022 . Per AWS D1.1 The minimum diameter of the hole for the plug shall be no less than the thickness of the part containing it plus 5/16(8mm) preferably rounded to the next greater odd 1/16". The maximum width shall equal the minimum width plus 1/8"(3mm) or 2-1/4 times the thickness of the member,which ever is greater. For slotted holes it is the same as above . Plug Welding. Honda does not indicate a specific plug weld nugget size in their collision repair information. Per the Honda/Acura Body Repair Basic manual, MAG Welding - Plug Welding - Body Basic: "This section provides a chart on what size hole will need to be drilled depending on the metal thickness. To determine the thickness of the parts .

Plug Welding. Plug welding, also known as hole welding, involves joining two metal pieces by filling a hole in the top piece with weld material, which then fuses with the bottom piece. This method creates a strong, durable bond and is commonly used in automotive and manufacturing applications. Spot WeldingFree Shipping - Bob Drake Weld-In Hole Repair Kits with qualifying orders of 9. Shop Patch Panels at Summit Racing. Off 0 / Off 0 / Off 00 - Use Promo Code: CYBER. Vehicle/Engine Search Vehicle/Engine Search Make/Model Search Make/Engine Search Departments; Brands; Savings Central . Weld Symbol: A small circle or dot is placed at the intersection of the reference line to indicate the location of the puddle weld. Weld Size: The size or diameter of the puddle weld is indicated by placing a dimension value alongside the weld symbol.This value specifies the desired size of the weld in inches or millimeters. Additional Specifications: Additional .

Your other option is to plug weld. You can drill 1 inch holes on one side of the tube and a 1/4 in holes on the side of tube to mate to the sheet. With the mig gun you can plug weld the 1/4 in hole to the sheet. Both methods will yield a clean face of . All MetalShaping > General Metal Shaping Discussion > Basic questions and answers: Rosette (Plug) Welds On Sheet MetalThese 11-gauge welding discs are designed to fill the holes in the heavier gauge metal areas of a car, such as the frame. This 29-piece kit includes sheet metal patches in several conventional hole sizes. The patch itself is slightly undersized to allow it to fit cleanly into the hole, however, the real icing on the cake is the tabs surrounding each circle. The tabs along the perimeter center . For thicker parts, plug welding, or rosette welding, is recommended. This technique is a specialised type of spot welding performed by TIG welders, where holes are cut into one sheet, and the metal is melted to fill the hole and fuse the parts together. . the spot weld to ensure a tight fit and strong weld. For thin sheet metal, a drill bit .

Plug Weld Hole Size Calculation-Example: 1/4″ steel would be equivalent to .25″ . You can also drill small holes through both pieces of sheet metal and use blind hole panel holders for a precise fit-up. Frame stretch; A frame stretch is where you cut the frame in half. Add a section of frame in between the cut to lengthen the wheelbase.

These 12-gauge welding discs are designed to fill the holes in the heavier gauge metal areas of a car, including the frame and any weight-bearing floor ; This 29-piece kit includes sheet metal patches in several conventional hole sizes ; 12-gauge steel (approximately 0.1046" or 7/64") Tabs around disc allow for strong butt-weld What is the best technique for joining long lengths of 24 gauge sheet metal with O/A? The project outlined using a MIG welder, by doing what the author called button hole welds. He drilled holes on one piece and then over lapped the second piece, and I assume migged inside the hole. Does this technique work similarly using OA with or without a filler?

plug weld vs spot

customized aluminium cnc milling machining service

Experience quick and hassle-free magnetic charging with the UAG wireless charging pad. Integrated magnets align to deliver charging speeds up to 15 .

what size hole for plug weld sheet metal|plug weld vs spot