application of cnc machine slideshare This document discusses computer numerical control (CNC) machines. It . Belson Steel offers Scrap Containers and Box Drop-Off and Pick-Up services to cover your project or business in removing scrap metal. Monday – Friday: 8:00 a.m. - 12:00 p.m. and 12:30 p.m. - 3:30 p.m. Saturday: 8:00 a.m. - 12:00 p.m. Sunday: Closed

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Jumbo-size your storage with the model 297-3-02 steel super-side truck box featuring a brite white Armor-tuf® powder coat finish that ensures year of dependability and has a storage capacity of 21.4 Cu. Ft.

CNC machines are computer-controlled machine tools that can be programmed to automatically perform tasks like cutting, drilling, grinding, milling, turning, and others. Key .This document discusses computer numerical control (CNC) machines. It .

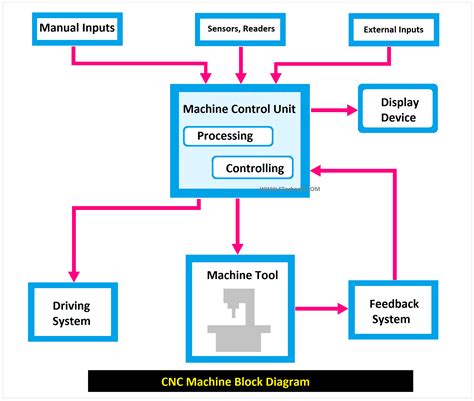

The key elements of a CNC machine are described as the input device, machine .CNC machining uses computer-controlled machine tools to precisely cut metal or . This document discusses computer numerical control (CNC) machines. It begins by defining CNC machines and providing a brief history, noting their development from numerically controlled machines in 1949 to . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation .

CNC Machines • CNC means Computerized Numerical Control machine. In this meaning the world Numerical control is very important, it replace the operator control of machine to the Numerical Control of machine. Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • . The CNC Machining is an Computer Numerical Control (CNC) machines are automated milling devices that make industrial components without direct human assistance. They use coded instructions that are sent to an .

CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine tool, driving system, feedback devices, and .Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining .Introduction CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces FIGURE CNC milling machines can produce complex part surfaces that .By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as .

CNC machines are computer-controlled machine tools that can be programmed to automatically perform tasks like cutting, drilling, grinding, milling, turning, and others. Key elements of a CNC machine include inputs, machine control units, machine tools, drives, feedback devices, and displays. This document discusses computer numerical control (CNC) machines. It begins by defining CNC machines and providing a brief history, noting their development from numerically controlled machines in 1949 to modern CNC machines linked to computers.

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. CNC Machines • CNC means Computerized Numerical Control machine. In this meaning the world Numerical control is very important, it replace the operator control of machine to the Numerical Control of machine. Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs is used in modern CNC machines for end-to-end component design. How CNC Works? • Controlled by G and M . The CNC Machining is an Computer Numerical Control (CNC) machines are automated milling devices that make industrial components without direct human assistance. They use coded instructions that are sent to an internal computer, which allows factories to fabricate parts accurately and quickly.

CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine tool, driving system, feedback devices, and display unit.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher EducationIntroduction CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces FIGURE CNC milling machines can produce complex part surfaces that would be virtually impossible to produce with manual milling machines. Photo courtesy of Haas Automation, Inc.

vintage steel cabinet

By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining.

schematic diagram of cnc machine

CNC machines are computer-controlled machine tools that can be programmed to automatically perform tasks like cutting, drilling, grinding, milling, turning, and others. Key elements of a CNC machine include inputs, machine control units, machine tools, drives, feedback devices, and displays.

This document discusses computer numerical control (CNC) machines. It begins by defining CNC machines and providing a brief history, noting their development from numerically controlled machines in 1949 to modern CNC machines linked to computers. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. CNC Machines • CNC means Computerized Numerical Control machine. In this meaning the world Numerical control is very important, it replace the operator control of machine to the Numerical Control of machine.

vintage round top metal lunch box

Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs is used in modern CNC machines for end-to-end component design. How CNC Works? • Controlled by G and M . The CNC Machining is an Computer Numerical Control (CNC) machines are automated milling devices that make industrial components without direct human assistance. They use coded instructions that are sent to an internal computer, which allows factories to fabricate parts accurately and quickly. CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine tool, driving system, feedback devices, and display unit.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher Education

Introduction CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces FIGURE CNC milling machines can produce complex part surfaces that would be virtually impossible to produce with manual milling machines. Photo courtesy of Haas Automation, Inc.

products made by milling machine

Steel City products are known for simplicity in design and innovation, such as producing the first box offering to standardize combination slotted/phillips screws on all boxes.

application of cnc machine slideshare|industries that use cnc machines