tig welding auto sheet metal Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. Quotes - UNITED CNC MACHINING

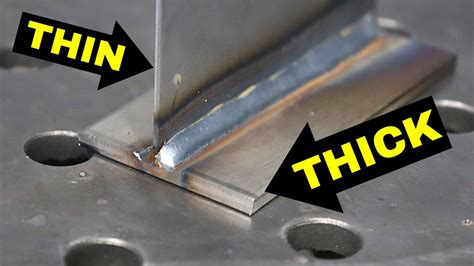

0 · welding thin to thick metal

1 · welding stainless steel sheet metal

2 · welding sheet metal without warping

3 · welding 14 gauge sheet metal

4 · tig welding stainless sheet metal

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

Proyectos - Estructuras Metálicas Con Uniones Atornilladas | Sistema .

Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. See more Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .

Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. I have tried autogenous approach on 18Ga using pulse and get some very good looking results, but find penetration an issue. Winding up peak current or peak on-time gets the penetration but the welds end up a lot . These panels are your usual automotive type, sheet metal, mild steel, 18 gauge, etc. These two panels in particular will be butt-welded. With the material being rather thin, you .

TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise .

On this episode of Make It Kustom I show you how to butt weld thin sheet metal body panels using tig welding.

When welding sheet metal with MIG or TIG, achieving precision and control is crucial to avoid warping and distortion. The following tips will guide you through the important aspects of welding techniques and material choices . The question often comes up about which method is better for the task – MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas). The short answer is that MIG welding and TIG welding .

Since it uses TIG welding, this is one of the best welders for automotive sheet metal out there. The machine uses plasma cutter technology, which is how you can weld without hazardous gasses. However, keep in mind . Wonder why factory seams tend to rust out? I personally was taught the mentality that when doing fabrication, bodywork, painting, or pretty much anything on a car that if your end results weren't better than factory then you are doing a shit job unless you are doing factory accurate restoration, which is cool to look at but very pointless in my opinion. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo.

welding thin to thick metal

I've done quite a bit of body repair honestly all processes make to much heat and you get warpage even spot welds if done in a row will warp gas brazing seems way too hot and I've found mig welding the whole seem is a nightmare to grind cause the weld will be much harder than the sheet metal I've had some success with Tig no filler but its only ideal for all new .

welding stainless steel sheet metal

When working with sheet metal, it’s important to consider the material’s thickness and composition. Thin sheet metals are highly susceptible to warping and burn-through if the welding settings are not properly dialed in. Achieving the perfect balance of amperage, voltage, tungsten size, and gas flow rate is the key to successful TIG welding on sheet metal.TIG Welding: 24 gauge to 1/4 inch TIG Welding: 24 gauge to 1/4 inch TIG Welding: (aluminum and steel) 16 gauge to 3/8 inch DC Stick Welding (steel) Pros. It has five welding processes and can deliver high amperage ranges with a duty cycle of up to 60%; Ideal for metal fabricators and welders that require versatility in their applications TIG welding is often used for auto body welds involving aluminum and stainless-steel parts. It is also used when welding thin metal sheets together, as it produces a strong and clean weld. . If so, keep these few tips in mind when welding the automotive sheet metal. Wear all Safety Equipment. Safety should be your priority. When welding auto . MIG vs. TIG Welding: Key Differences. MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular welding methods, each with distinct advantages: Weld Speed: MIG welding is faster, ideal for production settings, due to its automatic wire feed and broader arc. TIG welding is slower, requiring manual filler rod feeding and .

Mastering TIG Welding Techniques for Sheet Metal. TIG welding sheet metal demands precision and skill. Let’s explore the techniques that will elevate your welding game. Key Principles of TIG Welding Sheet Metal. Success in TIG welding sheet metal hinges on several core principles: Maintain a short arc length, typically 1/8 inch or less.

That’s gotta he a record, 5 replies, counting mine, and in 100% agreement. Hot fast “tacks” will impart less heat into the sheet metal than a continuous bead, even low amperage TIG welds. For a machine that you can use for both MIG and TIG weld auto-body work, we highly recommend this small multi-process welder. It’s low-priced, and while it doesn’t have the same TIG settings as the PRIMEWELD TIG225X 225 Amp TIG Welder, it’s excellent for beginners and experienced welders alike.. It’s particularly easy to learn on or develop new .

For most rust repair jobs, MIG welding is just fine and more straightforward for a novice metal worker. Oxy acetylene would be my third choice, and arc welding would be my fourth choice. As with welding on any metal, shrinkage and warping will happen. The thicker the metal, the less noticeable the effect.

Our Friends from @CrucibleCoachworks stopped by to show us the BEST way to reduce or eliminate warping on sheet metal! Welder: https://www.eastwood.com/eastw. We have the Eastwood MP140i which can do Flux, MIG, TIG or Stick welding. Here’s a comparison chart with all the different Eastwood welders currently available: WELDER COMPARISIONS. . What you’ll find with sheet . In general, though, TIG welding sheet metal can be done like TIG welding any other metal. Get your amps going, stick to a consistent travel speed and dab, dab, dab. If the fit-up is tight (and thin) enough, you don’t even need .

For automotive sheet metal, we recommend the Hobart 500559 Handler 140 MIG Welding Machine. It’s a great all-around welder that’s easy to use and reasonably priced. If you need a more heavy-duty welder, the LOTOS MIG175 175AMP MIG Welder is a great option. Welding Sheet Metal Overview. When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, commonly used in automotive and HVAC applications. MIG Welding Sheet Metal

steel storage cabinets with wheels

Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. MIG Welding (GMAW) MIG welding works fine for thin materials .

steel tool box for trailer

I get asked a lot of questions about Mig welding and Tig welding and so I decided to make a comparison video showing the pros and cons of both welding method. If you’re doing welding work on cars and need the diversity of a MIG and TIG welder, the Weldpro 200 Amp Multi-Process Machine is the best machine for automotive sheet metal. It’s one of the most technologically advanced multi-process welders available in .

On this video we are working on new body panels on a 72 Challenger where the Owner wants to shave down the door handles and marker lights front and rear. I g.If the black is mill scale you can weld through. Typically I remove it when I weld structural stuff. It only comes on my heavier plate, I've never seen it on gauged sheet metal, just on 1/8" and up. It can be removed with muriatic acid, but that's the nastiest stuff.

If you feel that you would like to help support Trev’s Blog channel please consider making a donation, money raised from donations will be used to buy tools . Spot welding is efficient for joining sheet metal, replicating factory welds, and preserving the original look of the vehicle. It’s less invasive, reducing the risk of warping and other damage. . What is the best welding technique for thin auto-body panels? A: TIG welding is generally the best option for thin panels due to its precision and . Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. . selection of welding parameters, such as current, voltage, and welding speed, based on the characteristics of the metal being welded. For TIG welding, . In the automotive industry, butt welding is commonly used for joining body . How to Prep Car Metal for TIG Welding. In welding, preparing the metal to be welded is one of the most important aspects of the welding job, despite the fact that it is one step often overlooked by novice or shoddy metalworkers. . Practice .

welding sheet metal without warping

Chapman Electric Supply carries underground enclosures, access boxes and covers in a wide range of sizes to meet your needs. They are ideal for telecommunications, underground utility. .

tig welding auto sheet metal|welding 14 gauge sheet metal