build wood cnc machine Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress . Buy Glue Gone 10 oz Adhesive Remover - Versatile, Gentle Solution for Stubborn Residue like Wax, Grease, Gum, Labels, Decals, and More - Works on Wood, Plastic, Glass, Metal, and Other Surfaces: Adhesive Removers - Amazon.com FREE DELIVERY possible on eligible purchases

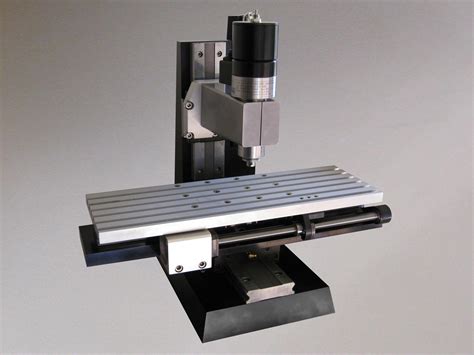

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge Size Chart PDF. (Click here) How many mm is 8 gauge? For different materials of steel, the same gauge will also correspond to different mm. What is 10 gauge in mm? What is 16 gauge thickness in mm?

A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" .DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be .

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or . A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years old and .DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try. Adding CNC to your shop doesn’t have to cost a small fortune; you can build a sturdy and accurate three-axis CNC router for about 00, and that price tag will get you most of the features you’ll find in commercial models selling for 00-00.

A chop saw, wood lathe, drill and a drill press, and finally a table saw — nothing fancy, but now with the CNC router he has a world of possibilities for projects!Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can choose to . A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years old and .

little metal bracket for back of wall clock

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

make your own cnc mill

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.

Adding CNC to your shop doesn’t have to cost a small fortune; you can build a sturdy and accurate three-axis CNC router for about 00, and that price tag will get you most of the features you’ll find in commercial models selling for 00-00. A chop saw, wood lathe, drill and a drill press, and finally a table saw — nothing fancy, but now with the CNC router he has a world of possibilities for projects!

litter-robot 3 connect self-cleaning electric cat litter box

make your own cnc machine

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.

build wood cnc machine|make your own cnc machine