cnc laser cutting machine programming factory Three software techniques to increase your laser-cutting efficiency include heat avoidance for thicker material, programming to cut parts with open profile geometry, and automatically applying different cutting conditions and .

HOW DO YOU WELD SHEET METAL WITH A STICK WELDER? Before you begin the process of welding a very thin sheet, there are a few things you must have. The first is a DC welder which can go .

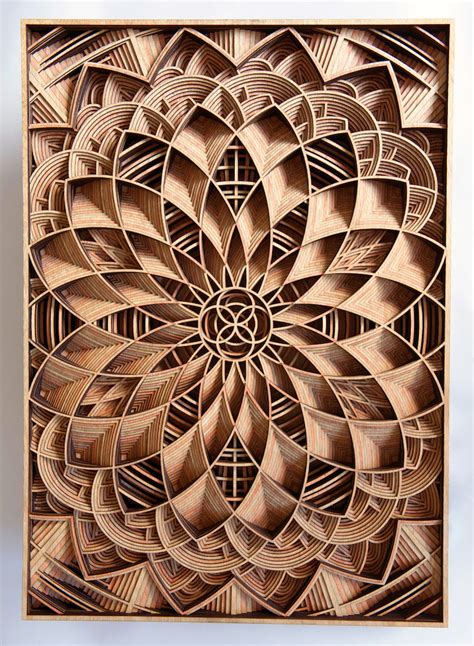

0 · lasercut works

1 · laser cutting requirements

2 · laser cutting guide

3 · laser cutter how it works

4 · laser cutter drawing

5 · how to make laser cutter

6 · cnc laser cutting machine near me

7 · cnc co2 laser cutting machine

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

From creating complex 3D geometries to optimizing machine travel paths for improved cutting time, we will explore advanced programming concepts that push the limits of what CNC laser .However, harnessing the full potential of a CNC laser cutting machine requires the .In this comprehensive guide, we'll dive deep into the world of CNC laser cutting machine programming, exploring its benefits, applications, and tips for mastering the art of .

We prepare technical drawings, CAD data and assemblies for sheet metal processing and create precisely fitting production models for your machines. We create NC programs for your laser, .However, harnessing the full potential of a CNC laser cutting machine requires the mastery of programming techniques. In this comprehensive guide, we will explore the intricacies of CNC . Three software techniques to increase your laser-cutting efficiency include heat avoidance for thicker material, programming to cut parts with open profile geometry, and automatically applying different cutting conditions and .

Instantly create an easy operational program for 3D cutting of tube or pipe. Utilizing automatic nesting results in increased yield and reduces material waste. The production status can be checked at a single glance with the scheduling . How to use CAD/CAM software to design laser engraving drawings, generate machine-readable AI, PDF, SVG, DXF, PLT, PNG, JPG, GIF, BMP file formats, and finally produce laser engraved projects. The 4 easy-to-follow .

Choose between these five free and six paid choices to find the perfect software for your laser cutting machine. Like any CNC machine, there’s a bit of a learning curve. CNC programming refers to a process of automatically creating a CNC machining program with the assist of a computer, CAD drawing & designing software, and CAM modeling & manufacturing software to control a CNC .From creating complex 3D geometries to optimizing machine travel paths for improved cutting time, we will explore advanced programming concepts that push the limits of what CNC laser cutting machines can achieve.

lasercut works

In this comprehensive guide, we'll dive deep into the world of CNC laser cutting machine programming, exploring its benefits, applications, and tips for mastering the art of programming these powerful machines. Here's our top ranked laser engraving and cutting software, based on hundreds of tests and an in-depth feature comparison. Check out our screenshots of each tool.We prepare technical drawings, CAD data and assemblies for sheet metal processing and create precisely fitting production models for your machines. We create NC programs for your laser, punching and bending machines and other technologies.However, harnessing the full potential of a CNC laser cutting machine requires the mastery of programming techniques. In this comprehensive guide, we will explore the intricacies of CNC laser cutting machine programming, providing you with the knowledge needed to .

Three software techniques to increase your laser-cutting efficiency include heat avoidance for thicker material, programming to cut parts with open profile geometry, and automatically applying different cutting conditions and speeds for different materials.Instantly create an easy operational program for 3D cutting of tube or pipe. Utilizing automatic nesting results in increased yield and reduces material waste. The production status can be checked at a single glance with the scheduling function. Automatic batch mode significantly reduces work time.

How to use CAD/CAM software to design laser engraving drawings, generate machine-readable AI, PDF, SVG, DXF, PLT, PNG, JPG, GIF, BMP file formats, and finally produce laser engraved projects. The 4 easy-to-follow steps are listed below:

Choose between these five free and six paid choices to find the perfect software for your laser cutting machine. Like any CNC machine, there’s a bit of a learning curve. CNC programming refers to a process of automatically creating a CNC machining program with the assist of a computer, CAD drawing & designing software, and CAM modeling & manufacturing software to control a CNC machine to work.From creating complex 3D geometries to optimizing machine travel paths for improved cutting time, we will explore advanced programming concepts that push the limits of what CNC laser cutting machines can achieve.

In this comprehensive guide, we'll dive deep into the world of CNC laser cutting machine programming, exploring its benefits, applications, and tips for mastering the art of programming these powerful machines. Here's our top ranked laser engraving and cutting software, based on hundreds of tests and an in-depth feature comparison. Check out our screenshots of each tool.

We prepare technical drawings, CAD data and assemblies for sheet metal processing and create precisely fitting production models for your machines. We create NC programs for your laser, punching and bending machines and other technologies.However, harnessing the full potential of a CNC laser cutting machine requires the mastery of programming techniques. In this comprehensive guide, we will explore the intricacies of CNC laser cutting machine programming, providing you with the knowledge needed to .

laser cutting requirements

Three software techniques to increase your laser-cutting efficiency include heat avoidance for thicker material, programming to cut parts with open profile geometry, and automatically applying different cutting conditions and speeds for different materials.Instantly create an easy operational program for 3D cutting of tube or pipe. Utilizing automatic nesting results in increased yield and reduces material waste. The production status can be checked at a single glance with the scheduling function. Automatic batch mode significantly reduces work time. How to use CAD/CAM software to design laser engraving drawings, generate machine-readable AI, PDF, SVG, DXF, PLT, PNG, JPG, GIF, BMP file formats, and finally produce laser engraved projects. The 4 easy-to-follow steps are listed below: Choose between these five free and six paid choices to find the perfect software for your laser cutting machine. Like any CNC machine, there’s a bit of a learning curve.

custom cnc carbon fiber manufacturing

custom cabinet manufacturing parts list

Start at switch box and run 14-3 or 12-3 wire from switch to junction box that you have a constant hot and neutral. In that box (lets call it box #1) new wire black goes to hot, white to neutral. Red will become your hot for all the lights.

cnc laser cutting machine programming factory|laser cutter drawing