how to calculate spring back for sheet metal Calculate the required force to bend a piece of sheet metal using V-bending, a . wholesale cnc aluminum milling parts,SLD Precision offers top-quality CNC milling parts for various applications. With our advanced CNC milling capabilities, we deliver precise and .

0 · springback sheet metal bending

1 · spring back factor calculator

2 · spring back calculator sheet metal

3 · spring back calculator ks

4 · spring back angle calculator

5 · metal springback formula

6 · metal springback calculator

7 · how to calculate spring back

One of the most professional manufacturers and suppliers of CNC Auto Parts in China is Huaner. Additionally, Our factory provides customized CNC Auto Parts at a cheap price. We welcome clients to buy our wholesale goods, and we will also provide them with specific discounts.

Calculates the final bend radius and bend angle that occurs from springback when bending a piece of sheet metal.Calculate the required force to bend a piece of sheet metal using V-bending, a .Milling Step-over Distance - Bending Springback Calculator - CustomPart.NetMaterial Usage - Bending Springback Calculator - CustomPart.Net

Calculate the surface roughness for a turning operation based on the tool nose .

Cooling Time - Bending Springback Calculator - CustomPart.Net

Calculate the required force to deep draw a piece of sheet metal based on the .

Calculate the final bend radius and angle of sheet metal after bending, considering the spring back factor, material properties and initial conditions. Enter the material thickness, K-factor, material, initial bend radius and angle, and . To calculate the Springback Factor (SBF), we use the following formula: \ [ SBF = \frac {BDA} {BTA} \] where: SBF is the Springback Factor, BDA is the bending angle in .

Managing spring back presents a unique challenge in many sheet metal forming processes. Understanding how spring back impacts different forming techniques allows us to employ specific strategies that minimize its impact and ensure the . Have you ever wondered why some metal parts spring back after bending? In this article, we’ll explore the fascinating world of bending dies and how to accurately predict springback. You’ll learn practical tips and formulas to .

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations.

Calculating Springback. Accurately calculating springback requires understanding several factors: Modulus of Elasticity (MOE): Also known as Young's modulus, it measures a .Calculating Sheet Metal Bending Springback. The springback phenomenon in sheet metal bending is a crucial factor to consider for achieving accurate final bend angles. Springback .Learn how to calculate and mitigate springback effect in sheet metal fabrication using AutoForm simulation technology. Find out how different material characteristics, bending angles, and forming methods affect springback .

In recent years the spring back calculation of a sheet metal part after forming has achieved a high accuracy. Today we are able to calculate the spring back amount after all forming operations of the part including trimming, piercing and reforming. But the spring back of a single sheet metal part is only the first step to solve the problem. Spring back in Sheet Metals. . Upon completion of sheet metal, deep-drawn and stretch-drawn parts spring back and thereby affect the dimensional accuracy of a finished part. . Degrees of spring back (D): It’s used to calculate bend allowances and bend deductions. D = [Ri / (Mt × 2.1)] × Material factor K. Where, Ri is inside the bend . Hi Friends,In this video you will learn Spring back effects and how to avoid spring back in sheet metal design#mechanicaldesignadda#molddesign#creotutorialMe.

Due to the fact the sheet metal work hardens during forming/drawing, it is desirable to stretch a sheet metal part as much as possible to increase part strength, and thereby increase the rigidness of the part and lessen the effect of springback. Stretch forming is often a more effective solution to springback problems than direct compensation. The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. .Springback is that force that shows up at the end of each bend, a small geometric variation that occurs on the material due to the release that occurs after the tools of our tube bending machine are opened. All this is normal, every material, every thickness, every radius has a different springback. Of course the springback can be calculated and it is very important to do so in .Calculating Spring Back. The spring bacK-Factor, commonly denoted by Ks, is the relation between the initial and final angles. A spring bacK-Factor of Ks=1 means there is no Spring Back, where a value of 0 means total Spring Back. To calculate the spring bacK-Factor ahead of a test piece it is important to understand that the bend radius is .

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. . These properties directly influence the material’s behavior during bending, affecting the spring back phenomenon and the required . In This Tutorials We'll Discuss Spring Back Value and Bend Allowance Press Tool Design. Here We'll Calculate Set back value , Bend Allowance, Bend Deduction,.Metal weight calculator online - free steel weight calculator. Has pre-entered densities for dozens of commonly-used metals and metal alloys like steel, aluminum, nickel, iron, copper, cadmium, gold, silver, etc. Calculate the weight of a steel beam, bar, tube, profiles, channels, or a .The thickness of sheet metal directly impacts the spring back. Thicker materials tend to spring back less than thinner ones. . To calculate the springback angle, subtract the actual bent angle of the part from the intended bend angle. This calculation helps determine the necessary overbending in the next production run to achieve the desired .

Bending Springback Calculator. After a bending operation, residual stresses will cause the sheet metal to spring back slightly. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to acheive the desired bend radius and bend angle. The final bend radius and bend angle can be approximated from the sheet thickness .Abstract In this study mathematical analysis of spring back was done for optimization of sheet metal bending process. The influence of sheet metal thickness, sheet metal type, friction, tool .

After bending, the material tends to spring back slightly, reducing the actual bend angle. To compensate for this springback effect, the bend allowance must be increased. The amount of springback varies depending on the material, the thickness, and the bend angle.

As the majority of the sheet is permanently deformed by plastic stresses and strains, any residual elastic stresses twist and distort the sheet metal shape. Materials with high Yield Strength (e.g. YS = 550MPa) tend to springback in a . Spring backهى ظاهرة إرتداد الشغلة وزيادة Size للاشترك بقناة اليوتيوب بالرابط ده 👇 :http://bit.ly/2srTfzm . This video shows how to evaluate springback defect in metal deformation. The video include how to model metal Deformation in 2D, deformaed and undeformed sha. In sheet metal stamping, springback manifests as a discrepancy between the final part geometry and the intended shape defined by the stamping die’s working surface. This deviation often results in parts falling outside specified tolerance ranges, potentially compromising the assembly precision and overall quality of the final product.

The compressive forces are less than the tensile forces on the outside of the bend, making your metal want to return to its old form. The amount of springback varies based on the piece of coiled metal you use. Springback Compensation Methods. Springback in sheet metal manufacturing is something you can predict to an extent. During the bending production process, due to the elastic recovery of the sheet metal, the deformation angle and radius of curvature of the sheet metal will increase. Therefore, a method of making the deformation degree of the sheet metal in the mold exceed the theoretical deformation degree can be used to reduce springback. Hot bending. Spring back Effect | Definition | Sheet metal | ENGINEERING STUDY MATERIALSSpringback is the geometric change made to a part at the end of the forming proces.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Spring-back-effects-in-sheet-metals Technical Blogs, Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts. Menu. Executive Programs. Workshops. Projects. Blogs. Careers. Student Reviews. For Business. More. Academic Training. Informative Articles. Find Jobs.

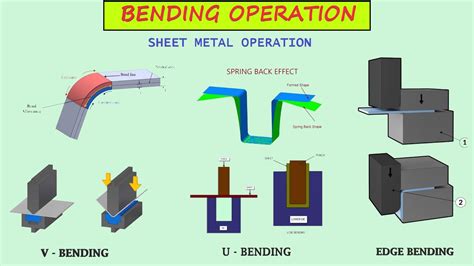

Sheet metal bending refers to the processing of changing the angle of sheet metal. Example, bending the sheet into a V shape, U shape, etc. Generally, there are two ways to sheet metal bending: One method is died bending, which used for sheet metal structures with complex structures, small volumes and mass processing. Regardless of size or power, all sheet metal bending techniques take standard variables into account when planning a job. Sheet metal forming technicians need to calculate metal springback reaction and compensate for metal bend allowance. Calculating sheet metal bend allowance and knowing how to reduce springback takes considerable expertise .

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.

metal enclosures for consumer units

Manufacture brass CNC turned parts, custom-made brass machining components, specializes in the production of custom brass turning parts.

how to calculate spring back for sheet metal|how to calculate spring back