onshape flatten sheet metal Finishing the sheet metal deactivates the selected sheet metal model and causes . Ultimate Tube Bender Parts Plus, Inc. can provide quality spare parts at an AFFORDABLE PRICE for most of your Pines Bender needs. We also provide on-site tubing bender service work, machine evaluations & inspections, bender refurbishing & rebuilding, buy & sell used equipment, and outsourcing your bending and fabricating requirements if necessary.

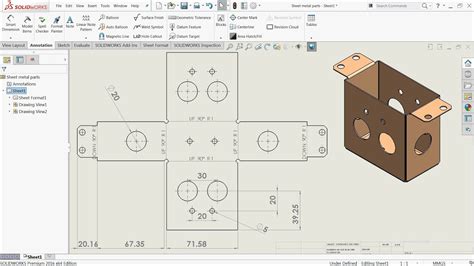

0 · simple sheet metal drawings

1 · sheet metal flat pattern layout

2 · sheet metal flat pattern

3 · sheet metal bending drawing

4 · onshape unfold sheet metal

5 · onshape sheet metal model

6 · onshape sheet metal flat pattern

7 · flat pattern sheet metal drawing

Tuckey Metal Fabricators, Inc. Take advantage of our full-service fabrication and welding for expert solutions to your OEM and custom fabrication challenges.

The Sheet metal table and flat view is where you can edit an existing sheet metal model’s bends, rips, and joints, in addition to viewing the sheet metal flat pattern. Click the .Finishing the sheet metal deactivates the selected sheet metal model and causes .

Modify Joint - Sheet Metal Table and Flat View - Onshape

Flange - Sheet Metal Table and Flat View - OnshapeThe Hem feature allows you to create one or more hems on existing sheet metal .Corner - Sheet Metal Table and Flat View - Onshape

Bend Relief - Sheet Metal Table and Flat View - Onshape

Flange - Create a wall for each edge selected, connected to the selected .

TAB - Sheet Metal Table and Flat View - OnshapeJust looking for a link to a tutorial on how to create a flat pattern for a sheetmetal .

One of the biggest benefits of Onshape’s Simultaneous Sheet Metal features is the ability to see the flat pattern update in real time as you make changes to . Sheet Metal Model. Create sheet metal parts by converting existing parts, extruding sketch curves (including arcs and splines to create rolled sheet metal), or thickening faces or sketches.In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing . Just looking for a link to a tutorial on how to create a flat pattern for a sheetmetal part and to create a flat pattern drawing view.

simple sheet metal drawings

I'm trying to stretch the boundaries for sheet metal flattening. A couple of years ago I was schooled in ruled based surfaces and what it means to flatten these things out. I've read the OS sheet metal manual and can make a .

sheet metal flat pattern layout

There is a sheet metal tab on the right side of your screen. When open you'll see the flat part and bend table. From there you can select the flat surface to sketch on. When you hit extrude it will default to remove. How to create a SHEET METAL cylinder and NET/FLATTENED part. Step by step. - YouTube. TEACHING THE NEXT GENERATIONTUTORIAL . Learn about Onshape's new filter for sheet metal flat patterns.Thanks for watching. Visit http://ptc.co/EGJc50G6nE2 to request your trial today! This webinar focused on all the tips you need to know to work with sheet metal flat patterns in Onshape. Topics covered included creating features in the sheet metal flat pattern, .

This webinar focuses on tips you need to know to work with sheet metal flat patterns in Onshape, including: creating features, exporting to DXF/DWG, and more. Resource Center > Videos > Tips for Working with Sheet Metal Flat Patterns . VIDEO DURATION: 29:17 June 26, 2018. .

No.1 for me is the ability to Flatten. Without any other sheet metal functionality this could be used to flatten both imported parts (originally modelled in another sheet metal package) and parts modelled in Onshape part studio as if they are .One highly requested feature that was recently added to Onshape is the ability to sketch in the Sheet Metal Flat View. This new feature allows you to create cuts in your sheet metal parts without the typical unfold/fold process that is required in older CAD systems.

Click to close the Sheet metal feature; the Finish sheet metal model feature is listed in the Feature list, has a flat pattern and a sheet metal table listing the bends and joints: When using an arc or spline to define a rolled wall, the sheet metal table and the flat pattern is .

Sheet metal is a great way to express your designs. The material is fairly affordable, and finding a local fabrication shop is just a Google search away. Additionally, with PTC’s Onshape, designing with sheet metal is even easier.The cloud-native CAD and PDM platform is improving the approach to sheet metal design and setting a new standard for streamlined manufacturing .Is there a way we can add an option to not include bend tangents on flat sheet metal parts? It is a major pain to program sheet metal in mastercam with all of these unnecessary intersections. When selecting an outside edge for example, mastercam will automatically trace around the part until it comes across an intersection.I Know this isn't 100% Onshape related but I have drawn a thin extrude item in Onshape and tried to flatten it in Solidworks.

Not as of yet, no. OS does not currently have the capability to deal with lofted sheet metal and similar shapes. You can make approximations with many small bends, but that's about the extent of it, for now.To access your flat view, simply left-click the sheet metal table and flat view icon on the righthand side of Onshape. This will launch the sheet metal table and flat view. From here, you can see a table with all the relevant bend information as well as a view of the sheet metal flat. To export your sheet metal flat view as DXF, right-click the .

cnc routing machine price

OMG! We need sheet metal lofts. I've been working on this simple transition most of the afternoon in Onshape. Finally got something close, but it would need to be welded instead of formed. I got a working flat pattern in Inventor in 5 minutes. ONSHAPE NEEDS SHEET METAL LOFTS! This should be the easiest thing, not the most frustrating thing.

cnc scroll saw machine

With a true sheet metal function this bend allowance is easily handled with bend deductions or k-factors resulting in dead-on flat patterns. Many bends are done with the inside bend radius less than the material thickness and a k-factor of less than .35.I noticed that the flat view tab is sometimes not available, after I open or switch to a part studio tab with a sheet metal model in it. Everything looks as usual, only the small tab with the unfolded icon on the right side of the model window isn't there.

I also work with sheet metal and would love to see an 'UNROLL' feature as well as a 'FLATTEN' feature. These tools are essential for this type of work. For OnShape to offer the ability to create a 3d shape then deconstruct it to be cut from sheet and then formed would really make this format my got-to product.Generating bends after converting a solid. 6. Variable Studios for Thickness Configurations. Onshape's Variable Studios can be used to drive sheet metal parameters like material thickness and bend data, which are typically tracked in gauge and bend tables.By mapping these values to global variables within Variable Studio, you can store them in a library document for easy reuse.

I have a model that contains 3 parts. they are all simple sheet metal flat parts. when I choose the Sheet Metal Flat View I can only see the first part usually "part 1" I dont need to see them all at once, but how do I choose which part ie: part 1, part 2, part 3, is displayed in the sheet metal view?@john_mcclary are you going through Mastercam to get a dxf profile for laser cutter? Seem like an unwanted extra step to me however whatever it takes to guarantee a 1:1. Come to think of it the Trumpf TruTops laser package has a . Click to close the Sheet metal feature; the Finish sheet metal model feature is listed in the Feature list, has a flat pattern and a sheet metal table listing the bends and joints: When using an arc or spline to define a rolled wall, the .Thank you, I have first drawn sketch , then gon to sheet metal, thickend it 2mm . Opened flat pattern, then opened new sketch on pattern and tried to

After creating the loft surface I then used the sheet metal command to convert the loft to sheet metal solid. It will create a part for each polygon segment. Use the add bend command to add bends where each segment connect.@kevin_ward365 You can insert your flat patterns in an Assembly and lay them out there (possibly by also bringing in a layout sketch). If you really want the flats in a Part Studio, you can first bring them into an assembly, then create a new Part Studio in-context of that assembly and use the Transform feature with copy-in-place to make the flats movable.

Using the Finish Sheet Metal Model feature turns off the Sheet Metal features for the part. Any features added after the Finish Sheet Metal Model feature do not appear in the flat view. This is useful if there are features that should appear in the folded view, but not the flat view, such as Form Tools or Rework Operations.

When you convert sheet metal components from legacy systems you often need different sheet metal bend geometry. Onshape uses a unique approach to bent and flattened states of a component that allows you to modify the design in both states. . Modifying the 3D and Flat Pattern. In the following example, we have a sheet metal model that requires .I have a sheet metal part, and would like to add a bend somewhere in the middle of an existing flat area. I can find how to add a bend by adding material on a free edge, but no way to bend a flat zone along a given line without adding material. The bending line could be defined by a segment in a sketch drawn on the face. Someone can help please?

Now you can either loft a solid between the sketches and convert to sheet metal. Or, loft faces and turn each facet fact into sheet metal. You'll need to indicate in the SM feature which facets are formed. The flat pattern will be perfect if you have your K factor right.The tutorials all show a sheet metal tab that is used to view the "simultaneous" flat view and table view. This icon is not visible for me. I have an Education Enterprise version of Onshape. I have attached a screenshot of my exercise from the tutorials and no .

+1 for me with sheet metal. I absolutely need this and would like to think it's on Onshape's list of additions. However at the moment I think there are higher priorities. I f sheet metal is 1-2 years away not sure what I am going to do to fill the gap while waiting.

sheet metal flat pattern

The Tuf-tite 4HD2 4-Hole Distribution Box comes complete with a lid. The Lid is 11" x 11". The Box is 15-1/2" tall and there is a 2" drop between inlet and outlets. The Distribution box is Used with 4" Pipe. About this item: The 4 hole distribution box includes the following; 3 - S-35 seal (Yellow) for thin-wall 4; 1 - P-10 plug (Orange) for .

onshape flatten sheet metal|sheet metal bending drawing