ball screw bearing for cnc machine Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer. The Company offers sheet metal fabrication machines, steel work, ultra clean metal manufacturing, and sub-assembly solutions for transportation, semiconductors, medical devices, pharmaceutical,.

0 · linear rails and ball screws

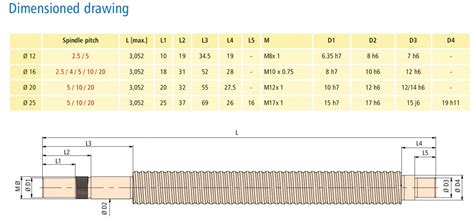

1 · ball screws standard sizes

2 · ball screw size guide

3 · ball screw size chart

4 · ball screw selection guide

5 · ball screw lifting mechanism

6 · anti backlash ball screws

7 · anti backlash ball screw nuts

As of Nov 7, 2024, the average hourly pay for a Sheet Metal Workers Union in the United States is $22.42 an hour. While ZipRecruiter is seeing hourly wages as high as $34.86 and as low as $12.74, the majority of Sheet Metal Workers Union wages currently range between $18.03 (25th percentile) to $25.96 (75th percentile) across the United States.

Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the . The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical . RBS’ Flagship product, the ball screw, consists of a screw that runs on ball bearings. Matching helical grooves on the screw and nut recirculate the bearings, making it an .This video detailed shows, how to replaced ball screw bearings on Vertical Machining Center.

Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer.Reciprocating ball screws are at the heart of many CNC machines, translating rotary motion into precise linear movement with minimal friction. This efficient power transmission mechanism .

Support Bearing. Rotate the ballscrew [5] by hand. If there is resistance or if it binds, the bearings are faulty. Remove the ballscrew [5] and check the support bearings and bearing pack to determine which components . If you’re experiencing these issues, it’s possible that you, your CNC service tech, or your maintenance team is making a mistake with just one component: the ball screw support bearing. Ball screw support bearings look .The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design. The channel is cleared by wipers ahead of time to .Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications.

Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router. How ball screw technology works. To understand ball screw technology, we need to start with two key components: the ball screw and the ball nut. Between these two, there are tiny ball bearings that circulate in tracks. The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical grooves large enough to hold ball bearings. The bearings are preloaded against the grooves of the screw to eliminate backlash. RBS’ Flagship product, the ball screw, consists of a screw that runs on ball bearings. Matching helical grooves on the screw and nut recirculate the bearings, making it an efficient way to convert angular-to-linear motion and vice versa. Ball screws are available in standard and metric sizes.This video detailed shows, how to replaced ball screw bearings on Vertical Machining Center.

Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer.

linear rails and ball screws

ball screws standard sizes

Reciprocating ball screws are at the heart of many CNC machines, translating rotary motion into precise linear movement with minimal friction. This efficient power transmission mechanism allows CNC machines to operate at high speeds without compromising accuracy. Support Bearing. Rotate the ballscrew [5] by hand. If there is resistance or if it binds, the bearings are faulty. Remove the ballscrew [5] and check the support bearings and bearing pack to determine which components need to be replaced.

If you’re experiencing these issues, it’s possible that you, your CNC service tech, or your maintenance team is making a mistake with just one component: the ball screw support bearing. Ball screw support bearings look like any standard ball bearing off the shelf, but they have one not so commonly known feature: operation under preload.

The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design. The channel is cleared by wipers ahead of time to prevent .Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications. Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router. How ball screw technology works. To understand ball screw technology, we need to start with two key components: the ball screw and the ball nut. Between these two, there are tiny ball bearings that circulate in tracks.

The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical grooves large enough to hold ball bearings. The bearings are preloaded against the grooves of the screw to eliminate backlash. RBS’ Flagship product, the ball screw, consists of a screw that runs on ball bearings. Matching helical grooves on the screw and nut recirculate the bearings, making it an efficient way to convert angular-to-linear motion and vice versa. Ball screws are available in standard and metric sizes.This video detailed shows, how to replaced ball screw bearings on Vertical Machining Center.

Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer.Reciprocating ball screws are at the heart of many CNC machines, translating rotary motion into precise linear movement with minimal friction. This efficient power transmission mechanism allows CNC machines to operate at high speeds without compromising accuracy. Support Bearing. Rotate the ballscrew [5] by hand. If there is resistance or if it binds, the bearings are faulty. Remove the ballscrew [5] and check the support bearings and bearing pack to determine which components need to be replaced.

If you’re experiencing these issues, it’s possible that you, your CNC service tech, or your maintenance team is making a mistake with just one component: the ball screw support bearing. Ball screw support bearings look like any standard ball bearing off the shelf, but they have one not so commonly known feature: operation under preload.

ball screw size guide

setup junction box in attic

Established in 1982 United Mechanical and Metal Fabricators, Inc., DBA UMEC, is a .

ball screw bearing for cnc machine|anti backlash ball screw nuts