cnc machine preventive maintenance schedule This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be . Steel braced design is typically either non-proprietary or proprietary “clip and bridging” bracing, or “flat strap and blocking” bracing periodically spaced along the height of the wall stud.

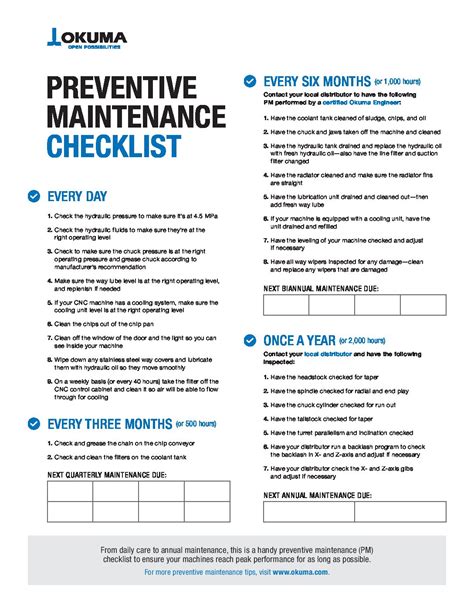

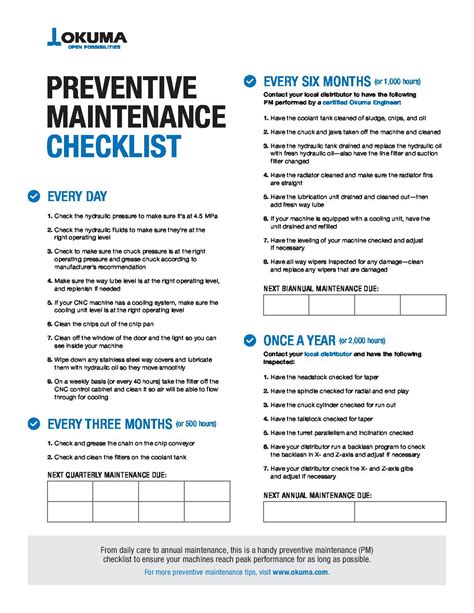

0 · preventive maintenance checklist pdf

1 · okuma preventive maintenance checklist

2 · okuma mechanical maintenance checklist

3 · okuma cnc machine maintenance checklist

4 · okuma cnc machine maintenance

5 · okuma cnc lathe maintenance

6 · mill maintenance checklist pdf

7 · cnc lathe maintenance checklist

MetalsCut4U offers custom fabricated u channel metal online in Florida, USA. Buy steel U channel sheet for sale in mild steel, stainless steel or aluminum.

In this comprehensive CNC machine preventive maintenance checklist, we have covered the importance of regular maintenance, provided detailed checklists for daily, weekly, monthly, quarterly, and annual tasks, and shared troubleshooting tips for common issues.In this blog post, we will provide you with a detailed preventive maintenance .This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be .

Your Preventive Maintenance Checklist (Schedule regular maintenance or servicing sessions, and maintain documentation of service/maintenance. Also, have a specific area for your employees to report issues.)

In this comprehensive CNC machine preventive maintenance checklist, we have covered the importance of regular maintenance, provided detailed checklists for daily, weekly, monthly, quarterly, and annual tasks, and shared troubleshooting tips for common issues.Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be achieved. Run spindle warm-up program. We recommend you put a tool holder in the spindle while running.

Your Preventive Maintenance Checklist (Schedule regular maintenance or servicing sessions, and maintain documentation of service/maintenance. Also, have a specific area for your employees to report issues.)In this blog post, we will provide you with a detailed preventive maintenance checklist specifically designed for CNC machines. And to facilitate your maintenance journey, we offer an Excel guide that simplifies the tracking and scheduling of maintenance tasks.It’s much easier to schedule preventive maintenance on all machines shop-wide every day or month or year. The following is not a comprehensive list, but it covers the majority of what needs to be done at different intervals.HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine level

Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.

preventive maintenance checklist pdf

Developing a comprehensive maintenance plan is the first step in effective preventive maintenance. Your plan should include: Scheduling: Determine how often you’ll perform maintenance tasks (daily, weekly, monthly, etc.). Task List: Create a list of specific tasks to be performed during each maintenance session.CNC DAILY MAINTENANCE CHECKLIST.xlsx - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides a daily preventive maintenance check list for a CNC machine.

vinyl fence with existing metal posts brackets

In this comprehensive CNC machine preventive maintenance checklist, we have covered the importance of regular maintenance, provided detailed checklists for daily, weekly, monthly, quarterly, and annual tasks, and shared troubleshooting tips for common issues.Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime.This document provides a list of tasks that are recommended to be completed on a daily and weekly basis to ensure the proper maintenance and performance of a Haas mill can be achieved. Run spindle warm-up program. We recommend you put a tool holder in the spindle while running.

Your Preventive Maintenance Checklist (Schedule regular maintenance or servicing sessions, and maintain documentation of service/maintenance. Also, have a specific area for your employees to report issues.)In this blog post, we will provide you with a detailed preventive maintenance checklist specifically designed for CNC machines. And to facilitate your maintenance journey, we offer an Excel guide that simplifies the tracking and scheduling of maintenance tasks.It’s much easier to schedule preventive maintenance on all machines shop-wide every day or month or year. The following is not a comprehensive list, but it covers the majority of what needs to be done at different intervals.

okuma preventive maintenance checklist

HAAS CNC MACHINE TOOL PREVENTIVE MAINTENANCE CHECKLIST © 2021 Haas Automation, Inc. | www.HaasCNC.com | 805-278-1800 MECHANICAL SYSTEM Verify machine levelEnsure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical.

Developing a comprehensive maintenance plan is the first step in effective preventive maintenance. Your plan should include: Scheduling: Determine how often you’ll perform maintenance tasks (daily, weekly, monthly, etc.). Task List: Create a list of specific tasks to be performed during each maintenance session.

okuma mechanical maintenance checklist

vinyl fence metal brackets

vintage silver metal soap box

Metal Works, Inc. has delivered high-quality precision sheet metal fabrication, finishing, and assembly services for over 35 years. Learn more.

cnc machine preventive maintenance schedule|okuma preventive maintenance checklist