sheet metal 90 elbow layout Learn how to make a hole sheet metal elbow.To understand it more easy, it´s good to have a 3D vision. want to know the pilot hole drill bit size chart based on screw size, gauge or material? Check this to find the pilot hole size for 1/4 lag screw & others.

0 · tapered cut 90 degrees elbow

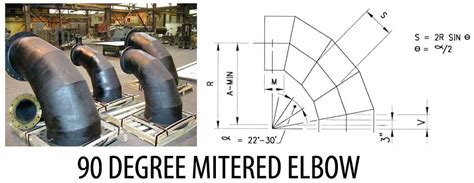

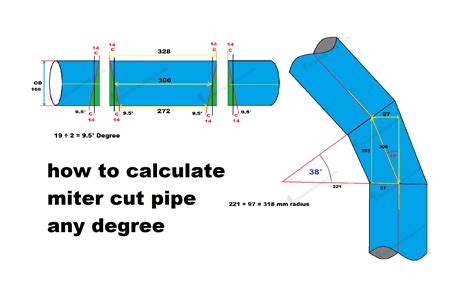

1 · pipe miter layout calculator

2 · mitered 90 degree elbow

3 · miter elbow calculation

4 · flat pattern bend calculator online

5 · 90 degree elbow wiring diagram

6 · 90 degree elbow cutting calculator

7 · 3 piece 90 degree layout

Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction

This video will show you how to layout a round elbow 90 degrees duct using a compass, t square, set square and others.Song Used:De0rbit - https://www.youtube. Our Transitional elbow will be offset from one side only. Here you will layout a 90 Deg. elbow 8/12 to 8/10 keeping one side straight. Draw your flat side pattern and bisect the heel and throat curves, establishing points 3 & 6.Round Elbow. For this example we will use a 6″ diameter-6″ throat radius-4pc-90°. Use the elbow rule (# of pcs × 2 − 2) to find the number of gores. For our example, it is 4 × 2 − 2 = 6. Each . Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.

Learn how to make a hole sheet metal elbow.To understand it more easy, it´s good to have a 3D vision.3 Piece 90°. Three piece turn-. We know that when building a two piece 90° turn we needed to cut two pieces at 45°. When making a three piece turn we will need to add one more piece of pipe and thus change the angle we need to cut. The .

Label the 6 points on the flat cheek A-F along with the actual amount of drop at that point. Draw in element lines, connecting the labeling. Create a True Length Diagram with ½ drop on the .

Large Round Elbow. When elbows or other round fittings, get too large, 12 divisions is no longer appropriate for the stretch-out. More divisions are required because the spacing of 12 .This book has been prepared as a text for use in Heat and Frost Insulator apprenticeship classes. It explains basic methods of drawing patterns for developing sheet metal and other types of .Full-bodied fittings, couplings, reducers, elbows, and taps are available with EASTERN TIGHT in even and odd sizes from 3” through 10” in diameter, and even sizes up to 36” in diameter. . 90° elbow x 300 in diameter, galvanized metal material.. Making 90° elbow was base on company standard process.._____hope y.

Make sure the fitting is sized correctly. Remember some of the sizing rules for y-branches: the crotch height must be ¾ of the base diameter (or 1.5x the radius), the small openings must equal the large- A2 + B2 = C2 can be used to size . Welcome to solid edge tutorial channel - Create a Sheetmetal Elbow for HVAC Application -This channel is dealing with everything about Solid edge Beginners T.Miter Bend Calculator is used to generate Flat Pattern Layout Marking or Fabrication layout of Miter Bend, Segment Bend, Cut Bend or Fabricated Bend. . 90 etc.) No. of Parts : Nos. (e.g 3, 4, 5 etc.) No. of Development Lines : Nos. (e.g 12, 24, 48 etc.) Calculate Clear. . Sheet Metal Manufacturing Industry, Insulation Industry.Use the standard elbow rule for the miter angle. The 2 end gores for any tapering elbow are always drawn using parallel line. Connect the end goes to create the middle gore. Notice that all the size change occurs through the heel section. Draw profiles on both end gores, complete with element lines and labeling

need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. . I hated these fittings. Layout AND assembly. They have their purpose but I get nightmares. . (what I call "Chicago bulls logo 90's") to cover up those corner spots for when you boys do them light .

Transfer this distance from the outside of the heel on the large end. It must be transferred from the outside, inwards to create a “square” for the heel section. From this new point, set you dividers to the heel and swing a 90° heel arc . Calculate the heel length by using the small end radius, plus the straight section.Available in E-Z Flange Jr. 6”- 24” diameter and E-Z Flange 26″- 120″ diameter sizes. 52” and larger in diameter 90 degree full sweep (1.5 x CL) elbows are fabricated using two 45 degree angles connected with a E-Z Flange and Barrel Clamp unless otherwise specified. 90 degree welded gored elbows are fabricated from 20-gauge galvanized material.Draw an elevation view of the flat radius throat radius heel (RTRH) cheek.; Bisect the heel and throat. Label the elevation view, starting from A-B and ending with E-F.; Draw in element lines connecting 4 triangles as shown.; At each point, we want to sub-label with the amount of drop at that point. So both A and B are 0%, C and D are 50% of the drop and E and F are the 100% of . Designing elbow is easy but when it came to joining practically its little bit tough if the segments are different in dimension , here is a small attempt to .

Her we will convert a 3D Solid body into sheet metal and divide the body in multiple number of part later convert into sheet metal format and saved as 2D fil. This tutorial show how to create sheet metal elbow and also demonstrate how to get the flat pattern for each section of the sheet metal elbow.It's bit tricky.Elbow Butterfly - Video - PDF . Video - PDF instructions Unequal Tee - Video - PDF instructions . The following videos can also be found on the Metal Layouts Vol. 2 flashdrive provided to each JATC from the IIIATF. Creating an Ellipse - Video Segmented 90 - Video Segmenting Equal Parts - Video Unequal Lateral Y - Video Tank Head Gores - Video .Sheet Metal Connectors, Inc. manufactures 90 degree square duct elbow fittings in a range of sizes and configurations. Square throat radius heel elbows are produced using state-of-the-art fabrication equipment in our yellow label union shops. . v corners, etc.) installed. 90 degree square duct elbows are also available knocked down to .

Fittings are fittings. I don't think much has changed on manual layout over the years. The old guy in the shop might have a few tricks, but an elbow 40 years ago is still and elbow today. As long as you size the duct properly it shouldn't matter.The ELBOW software module is for the development and layout of a multi-gored bend between two ducts in sheet and plate. TYPICAL APPLICATIONS Fabricated metal shapes used in Bulk Materials Handling - chutes Fluids Conveying - .

Layout of 90 elbow Layout of segments elbowLayout of 2 pcs elbow Layout of bendLayout of L type elbowLayout of cladding elbowLayout of sheet metal elbowLayou.

#90degelbow#development#layout

More divisions are required because the spacing of 12 becomes too great. Try and choose a number of divisions which keeps the spacing around 2”, so accuracy remains. We will layout using a quarter circle since the same quarter repeats in the pattern. Calculate the seam height and rise radius of the elbow . Calculate the blank size for the elbow

To fabricate an elbow from sheet metal, you will need the following tools and materials: . This information is essential for calculating the necessary dimensions and layout of the sheet metal. The angle of the elbow is typically measured in degrees, while the radius refers to the curvature of the bend. . a 90-degree elbow with a 6-inch .FLAT OVAL 90 DEGREE ELBOW. Part of our complete line of HVAC products, Flat Oval 90 Degree Welded Elbows from Sheet Metal Connectors, Inc. come assembled with fully welded seams and have been fabricated using state-of-the-art equipment in our yellow-label union shop. Flat oval duct has been designed for restricted space conditions that cannot accept round .

#ductwork #hvac #sheetmetal #ventilation #triangulation

metal pole barn shop houses inside pics

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .These elbows can be adjusted by twisting individual gores to change the angle of the fitting. 90 degree adjustable elbows may be used for angles from zero to 90 degrees to fit your application. Contact our team to get a quote or learn more about our .Equal Diameter 90 Degree Tee 45 16. Unequal Diameter 90 Degree Tee-Shop Method 49 17. Off Centre 90 Degree Tee 53 18. Oblique Tee 57 19. Round Elbow 61 Part III. Radial Line Pattern Development 20. Right Cone 69 21. Pyramid 73 . Sheet Metal Level 1. and • . • . About BCcampus Open Education . Pattern Development: Sheet Metal Level 1 . Pattern making for a round to round transition piece with an offset top and bottom. generally used in sheet metal fabrication for HVAC, food processing, etc..

tapered cut 90 degrees elbow

Elbow degree 90° Elbow Radius L R 1.5 D. 18 center line Pipe size 6″ / 8″ Pipe thickens stranded size. Elbow degree 90° Elbow Radius L R 1.5 D. 24 center line Pipe size. 10″ / 12″ miter cut elbow marking demo. पाइप के ऊपर सेंटर लाइन मार्किंग करने के लिए

pipe miter layout calculator

The choice between 0.8 mm and 0.9 mm MIG wire depends on the thickness of the metal being welded. 0.8 mm wire is suitable for welding thin metal sheets up to 3 mm thick, while 0.9 mm wire is better suited for thicker metals up to 6 mm thick.

sheet metal 90 elbow layout|3 piece 90 degree layout